Friction coefficient forecasting and setting method for cold-continuous-rolling high-speed rolling process

A technology of friction coefficient and rolling process, which is applied in the field of cold rolling production process, can solve the problems that have not made obvious progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

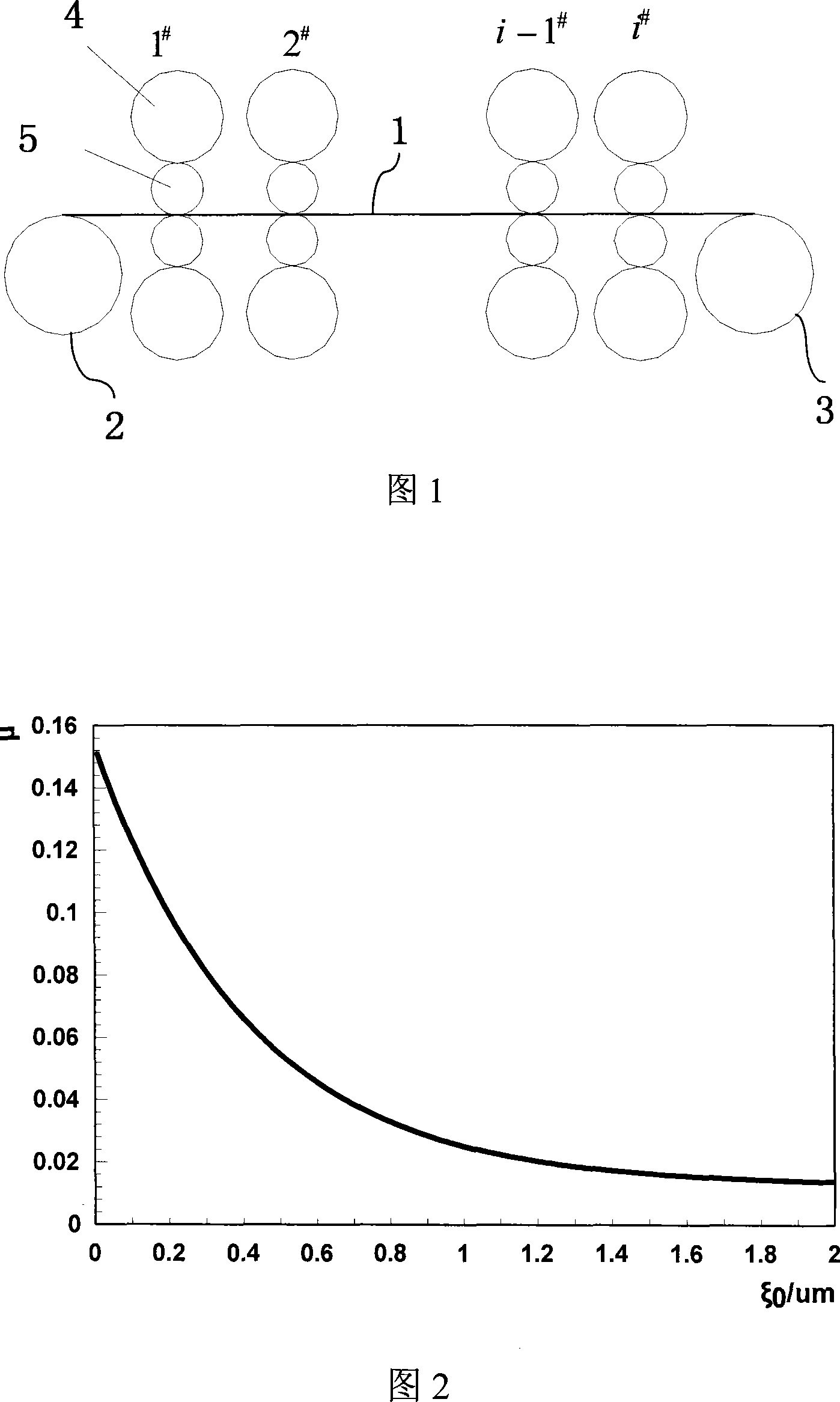

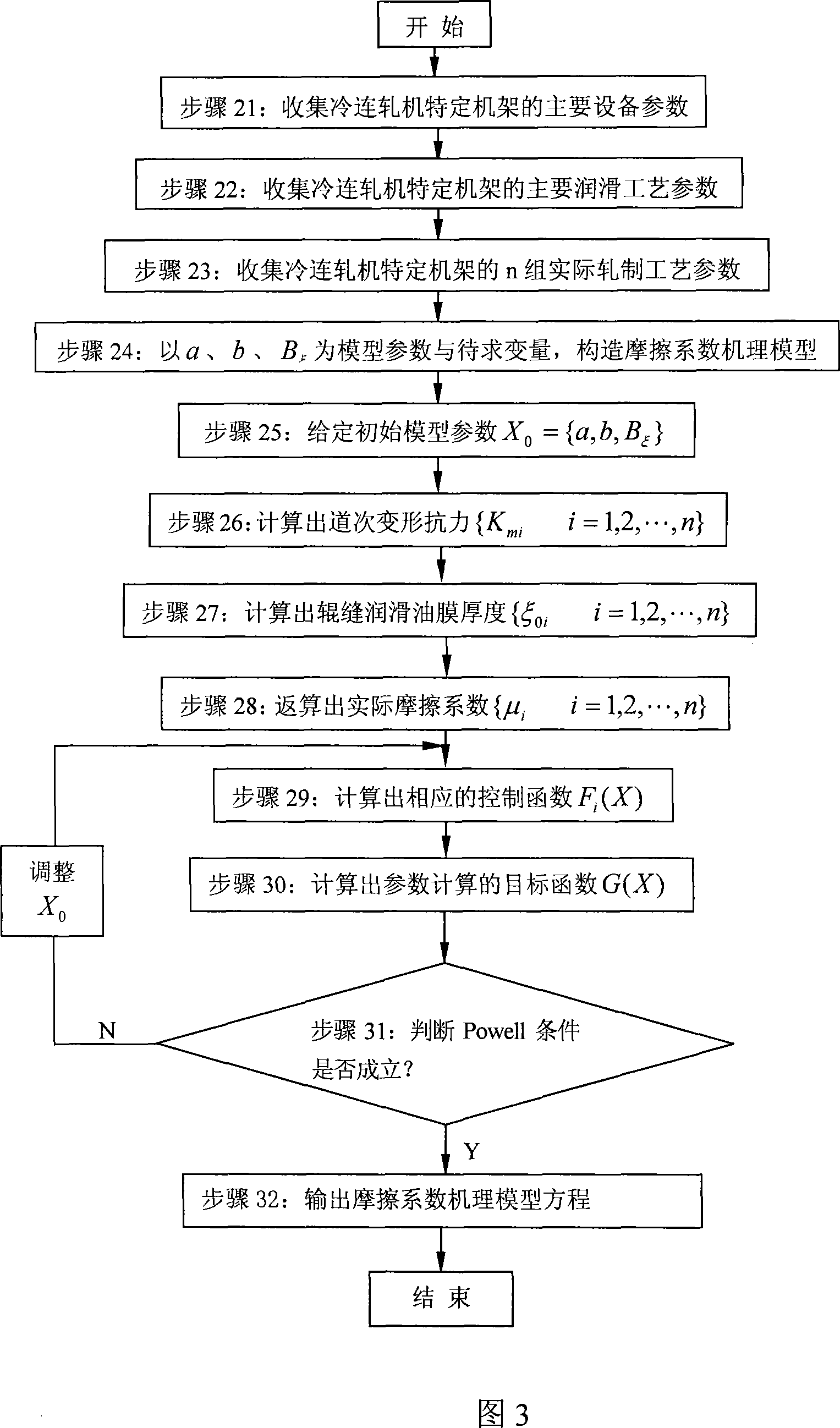

[0078] According to field experience, in the process of continuous cold rolling, in order to reduce the surface temperature of the roll and the strip, reduce the friction coefficient and friction force on the contact arc surface of the deformation zone, prevent the metal from sticking to the roll surface and reduce the wear of the roll, It is often necessary to spray a large amount of emulsion on the surface of the roll and the strip. In this way, in the high-speed rolling process of the cold tandem mill, the strip and the roll are not in direct contact, but through a certain thickness of lubricating oil film as a medium, so the value of the friction coefficient during the rolling process is almost completely determined by the contact surface According to the thickness of the lubricating layer, the state of the friction in the rolling deformation zone and the change trend of the friction coefficient can be simply judged. For example, as the thickness of the lubricating layer i...

Embodiment 2

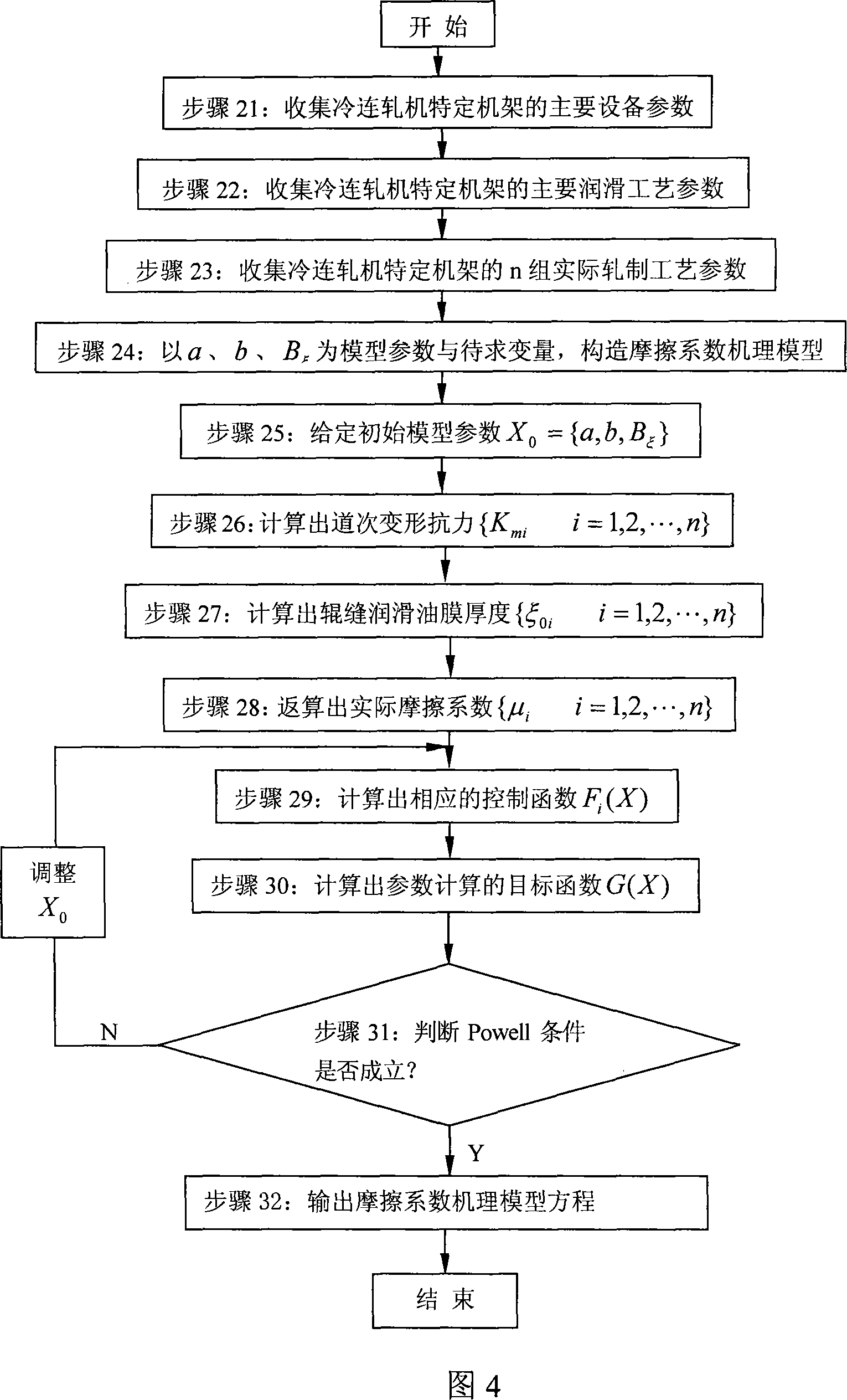

[0125] Generally speaking, for the high-speed rolling process of cold tandem rolling, one of the purposes of establishing the friction coefficient mechanism model is to realize the online prediction of the friction coefficient in the roll gap according to the known rolling process parameters and lubrication process parameters .

[0126] Fig. 3 is a flow chart of on-line forecasting and setting calculation of the friction coefficient of the tandem cold rolling mill in a preferred embodiment. This embodiment is used for online prediction and setting of the friction coefficient in the roll gap in the high-speed rolling process of cold tandem rolling.

[0127] First, in step 41, the main equipment parameters of the stand to be predicted in the tandem cold rolling mill are collected, including the radius R of the work roll, the original roughness Ra of the work roll r0 , Work roll roughness attenuation coefficient B L , embossing rate K rs and other parameters;

[0128] Subsequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com