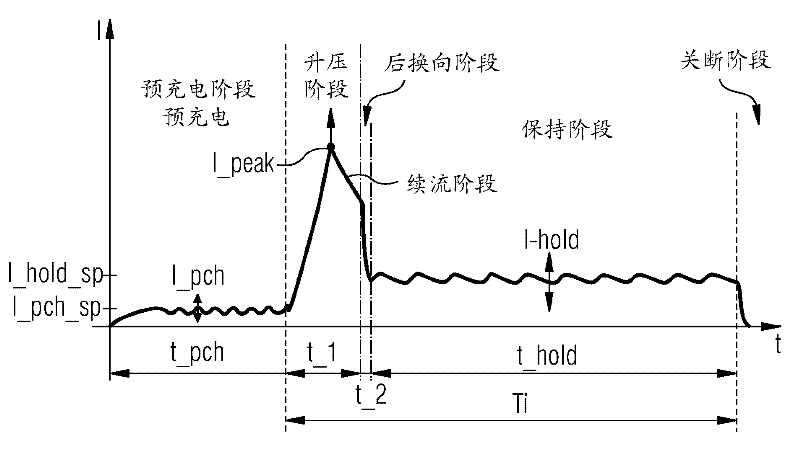

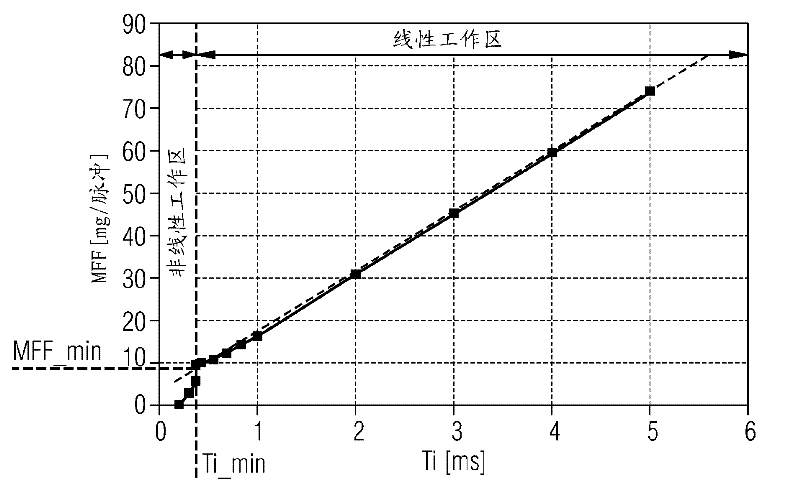

Use current integration to control the current flowing through the valve's coil drive

A coil drive, current integration technology, applied in electrical control, engine control, fuel injection control and other directions, can solve problems such as large deviation of injected fuel amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

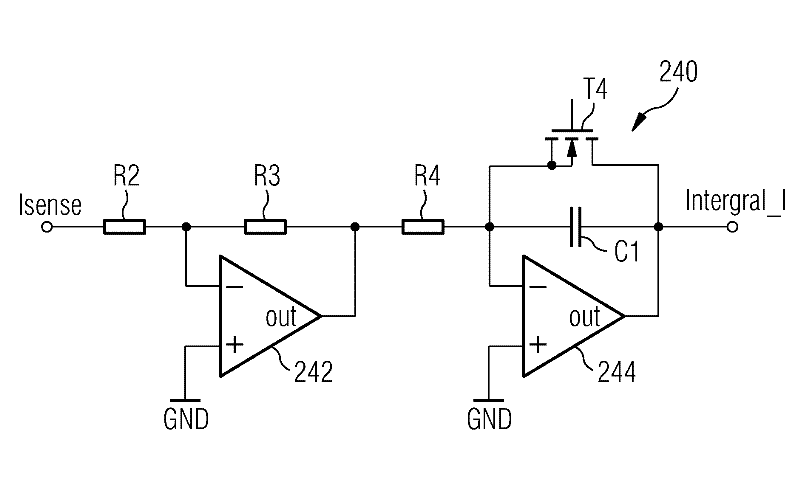

[0060] figure 1 An apparatus 100 for regulating current flow through a coil drive 110 of a direct injection valve is shown. The direct injection valve is not shown for reasons of clarity.

[0061] The regulating device 100 may be coupled to two voltage sources, wherein a first voltage source provides a first supply voltage Vbat and a second voltage source provides a second supply voltage Vboost. According to the exemplary embodiment shown here, the first supply voltage Vbat corresponds to the on-board voltage or the battery voltage of the motor vehicle. The second supply voltage Vboost is an amplified or boosted voltage, which is generated from the first supply voltage Vbat, for example by means of conventional DC-DC conversion.

[0062] The line segment driver 110 can be coupled to the first supply voltage Vbat via a first switching element T1 embodied as a transistor and to the second supply voltage Vboost via a second switching element T2 also embodied as a transistor. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com