Method for actuating a solenoid valve and associated device

A solenoid valve, current technology, applied in the direction of valve operation/release device, valve device, magnet, etc., can solve the problem of delaying the actual switching process of the solenoid valve, delaying the switching of the solenoid valve, unable to correct the delay, etc., to achieve a small injection volume, The effect of reducing electrical delay and shortening delay time

Inactive Publication Date: 2010-08-18

CONTINENTAL AUTOMOTIVE GMBH

View PDF4 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The problem with this usual actuation is that, due to the inductance of the magnetic coil, the actuating current is maintained for a certain time interval after the moment of switching off, thus delaying the actual switching process of the solenoid valve (Schaltvorgang)

Furthermore, in conventional injectors there is the problem that eddy currents are induced in the magnetic coil after the switch-off moment due to the rapid change of the actuating current, which counteract the cancellation of the magnetic field, which in turn delays the switching of the solenoid valve (Schalten)

This electrical delay due to eddy currents is particularly problematic when very small injection quantities and thus very short solenoid valve opening times are desired, since the aforementioned delay cannot be corrected

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

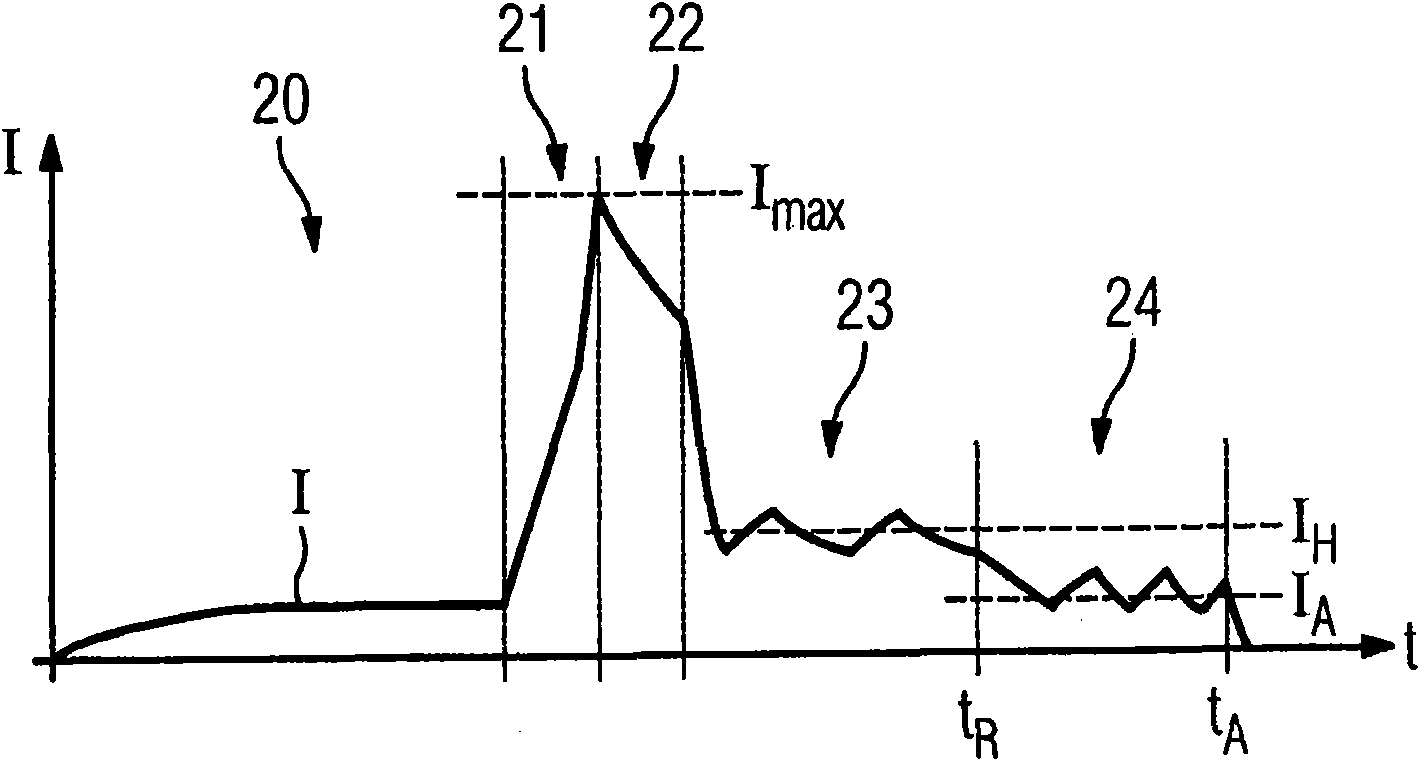

The invention relates to a method for actuating a solenoid valve (4) for generating precise opening and closing times of the solenoid valve (4). To this end, an actuating current (I) provided for actuating the solenoid valve (4) and applied to an actuating coil (5) of the solenoid valve (4) is already reducing in a reduction phase (24) prior to a switch-off point in time (tA) of the solenoid valve (4) relative to a maintained level (IH) of the actuating current (I), at which the solenoid valve (4) is reliably held in an actuating position (16).

Description

technical field The invention relates to a method for actuating a solenoid valve for high-pressure injection in a motor vehicle. The invention also relates to a device for carrying out the method. Background technique Controlled solenoid valves are often used to inject fuel directly into the motor vehicle engine. A defined (ie neither too little nor too much) injection quantity is thus desired, which can be achieved by precisely controlling the opening and closing times of the solenoid valves. Solenoid valves are usually actuated via a solenoid coil loaded with an actuating current. Typically, a yoke in the magnet coil is magnetized by the induced magnetic field. The actuating element acting as an armature is moved by the generated magnetic force against the spring force toward the yoke into the actuating position. In current actuation methods, the actuation current is generally controlled in such a way that the actuation current is increased in the precharging phase t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F02D41/20F02D41/40

CPCF02D41/40H01F7/1805F16K31/0675F02D2041/2058F02D41/20Y10T137/0318

Inventor C·哈根米勒A·迈耶-迪克

Owner CONTINENTAL AUTOMOTIVE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com