IC engine with oxygen jet in cylinder and oxygen-enriched combustion control

An internal combustion engine and engine technology, applied in the direction of engine control, engine components, fuel injection control, etc., to achieve the effects of easy control of the amount of oxygen injection, reduced cost, and flexible and diverse injection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

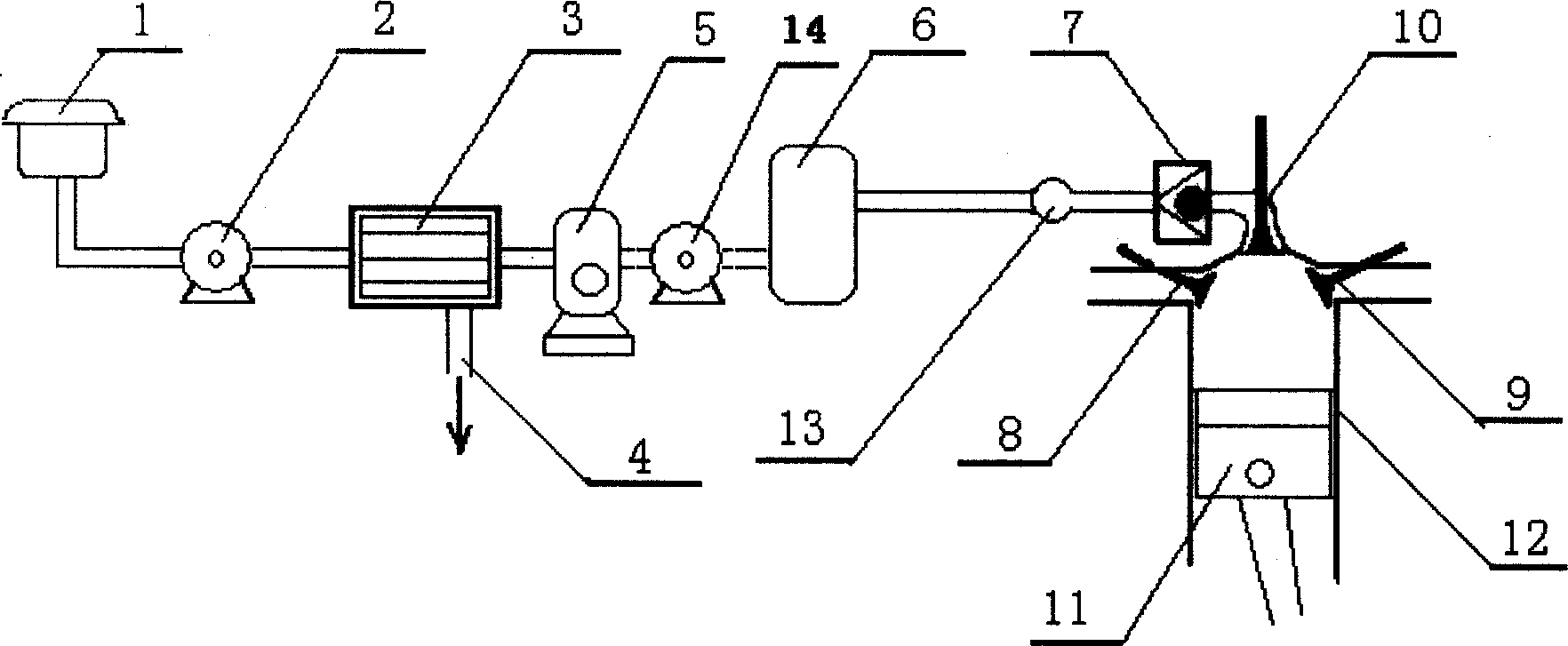

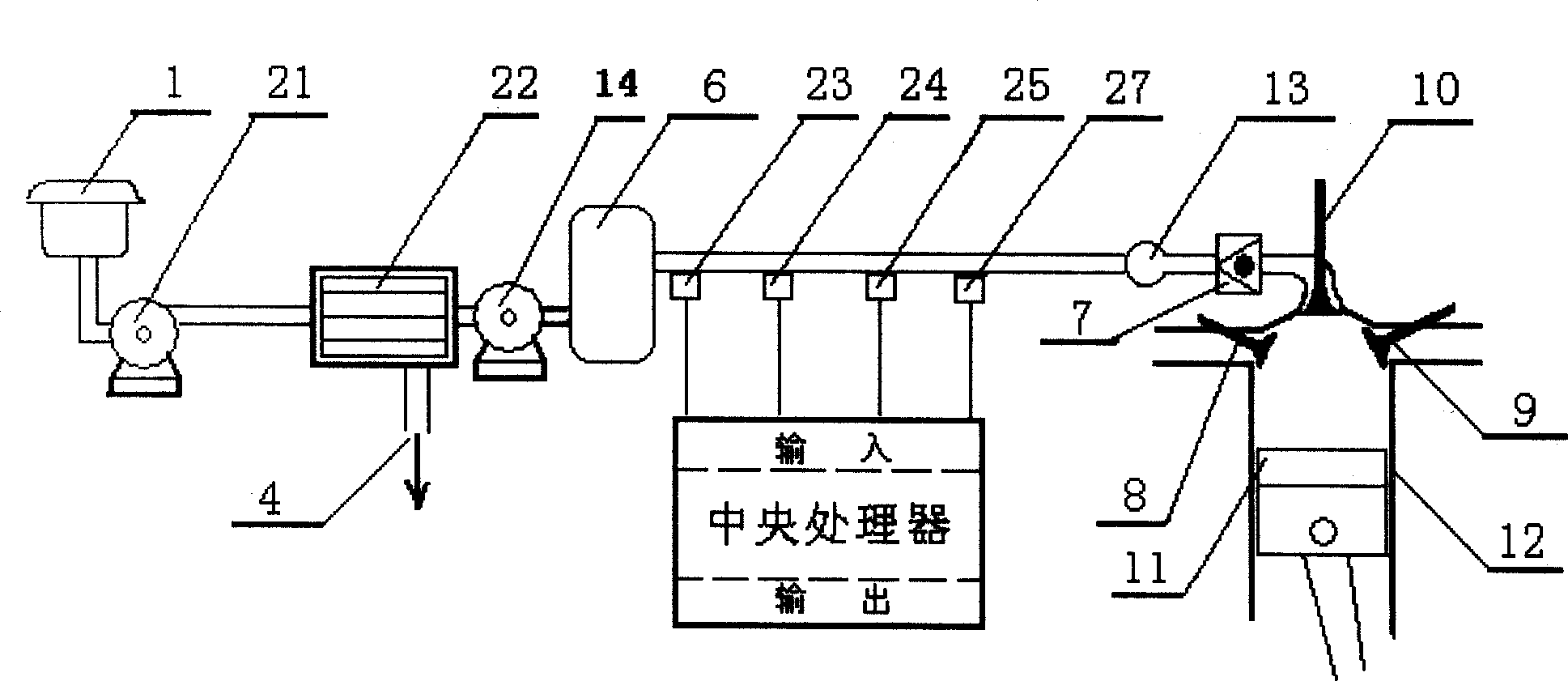

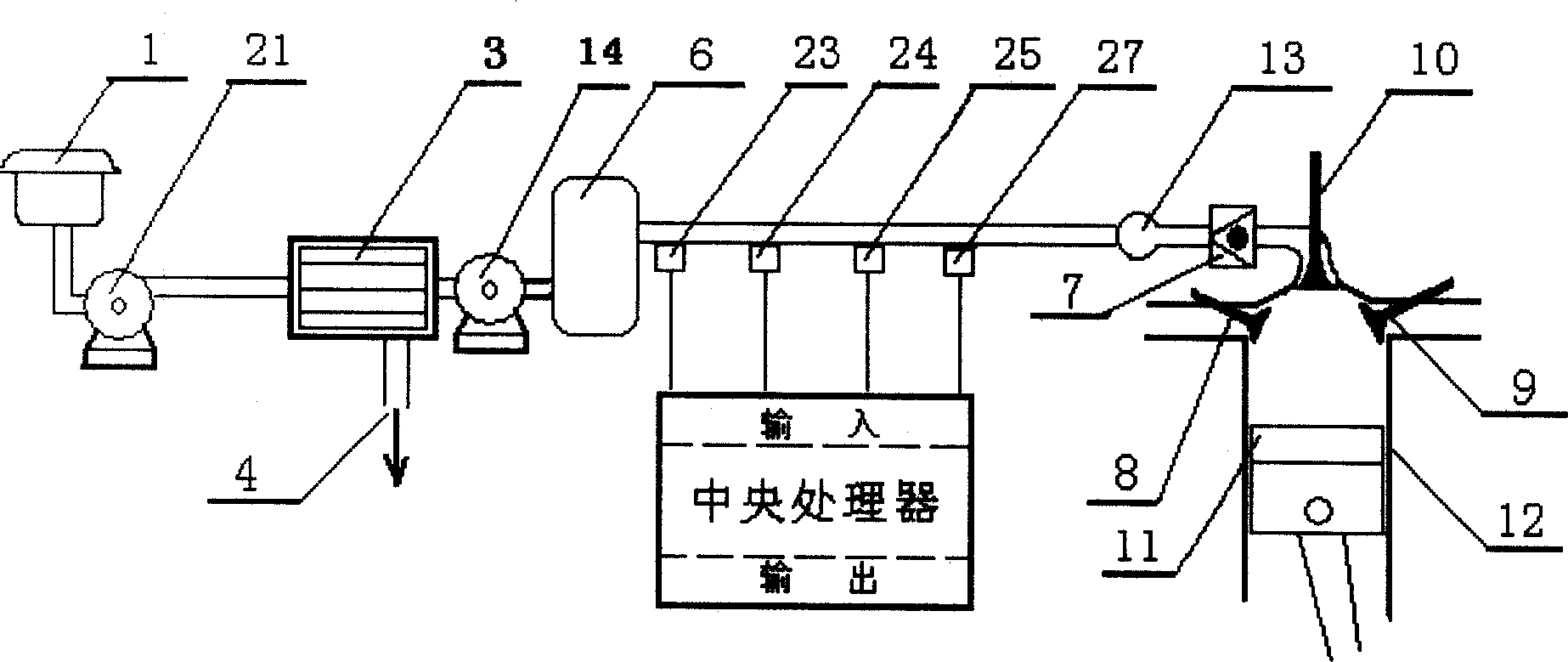

[0017] The technical scheme of the present invention is described in three parts according to the method of injecting oxygen in the cylinder, the internal combustion engine with oxygen injection in the cylinder, and the control method of oxygen-enriched combustion of the internal combustion engine.

[0018] In-cylinder oxygen injection method: a method for injecting oxygen-enriched gas into the cylinder of an internal combustion engine. On each cylinder combustion chamber of an existing internal combustion engine, at least one intake valve (can be an intake valve of the prior art, or But electromagnetic valve or electronic valve), the outlet of the added intake valve is communicated with the interior of the combustion chamber, equipped with oxygen-generating equipment to supply oxygen-enriched gas to the added intake valve, through the opening and closing control of the intake valve, Oxygen-enriched gas is injected into the combustion chamber during a certain period of time dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com