Combustion control device for an engine

A control device and engine technology, applied in the direction of engine control, automatic control, automatic control, etc., can solve problems such as reduction, cost increase, and fuel consumption rate reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

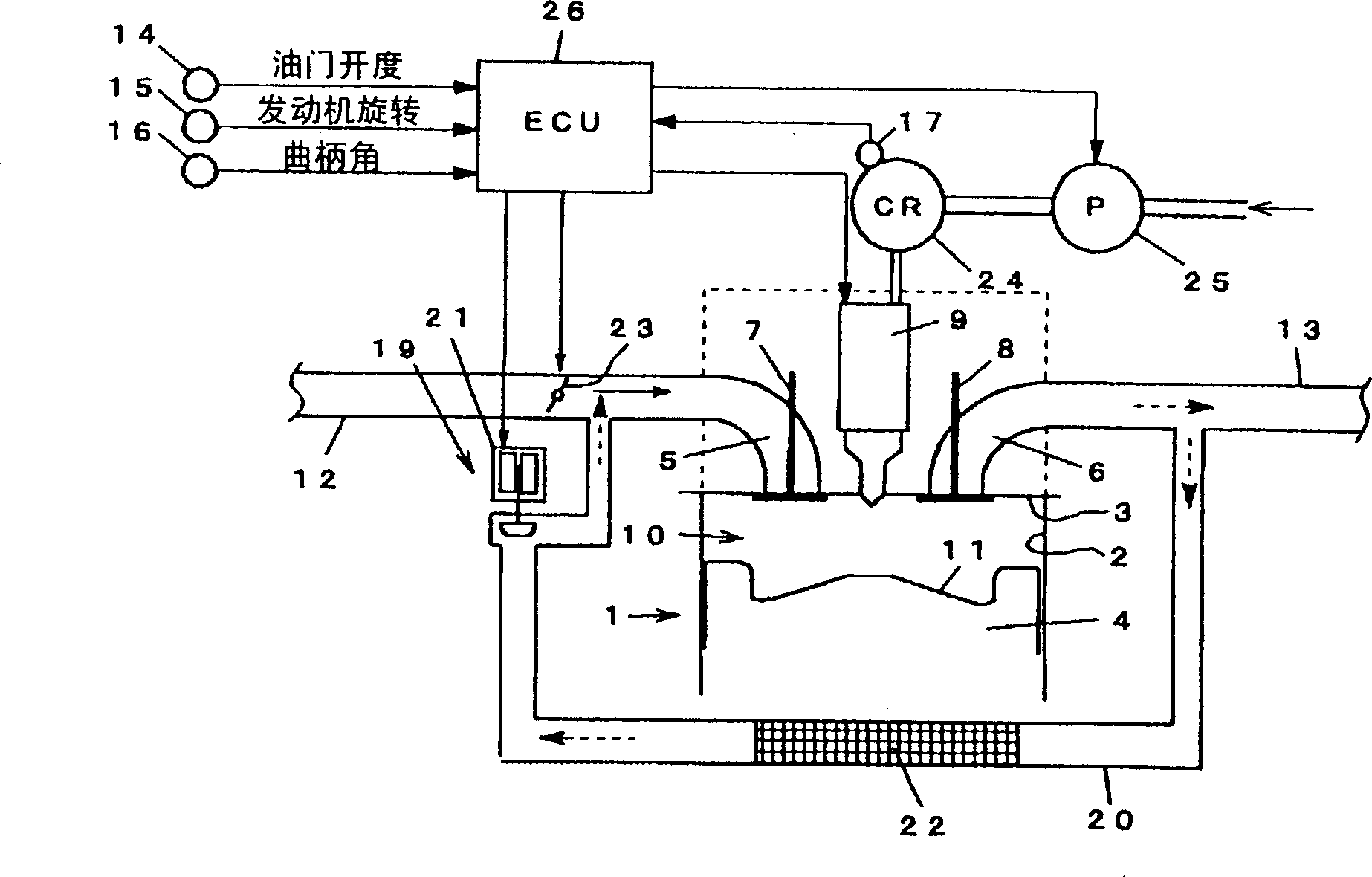

[0037] This embodiment is suitable for common rail direct injection diesel engines, refer to figure 1 The schematic structure will be described. figure 1 Only one cylinder is shown in , of course, there may be multiple cylinders.

[0038]Among the figure, 1 is engine body, is made of cylinder 2, cylinder head 3, piston 4, suction port 5, exhaust port 6, suction valve 7, exhaust valve 8, injector 9 etc. In the space between the cylinder 2 and the cylinder head 3, a combustion chamber 10 is formed. Fuel is directly injected into the combustion chamber 10 from the injector (combustion injection valve) 9 . A cavity 11 is formed at the top of the piston 4 as a part of the combustion chamber 10 . The cavity 11 is formed in the form of a concave combustion chamber with a raised bottom center. The injector 9 is arranged substantially coaxially with the cylinder 2, and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com