Multistage depressed collector structure of traveling wave tube and traveling wave tube

A collector and traveling wave tube technology, which is applied in the field of vacuum microwave electronic devices, can solve the problems of poor secondary electron suppression of backflow, easy formation of backflow, and low collector efficiency, so as to avoid processing and assembly and improve recovery efficiency , The effect of high collection and recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

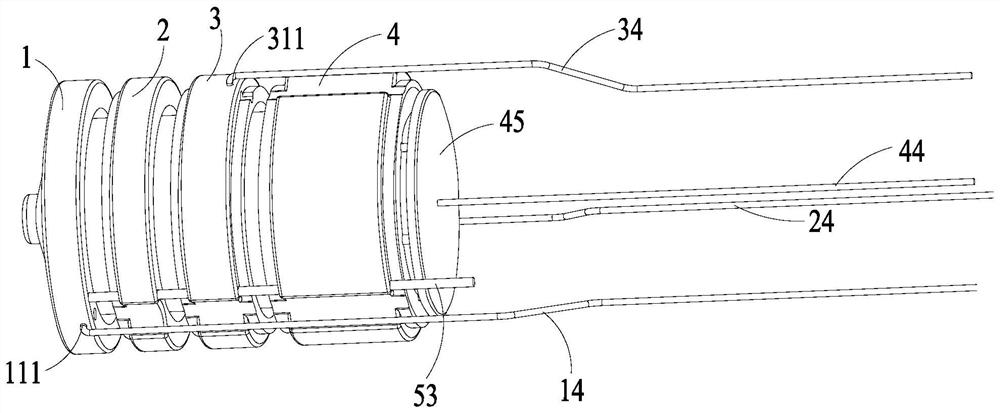

Embodiment 1

[0055] The invention provides a traveling wave tube multi-stage step-down collector structure, such as Figure 1-Figure 4 As shown, the collector structure includes an outer cylinder 5 having a housing chamber 51, a first collector assembly 1 and a second collector assembly arranged in the housing chamber 51 and sequentially distributed along the axial direction of the outer cylinder 5 2. The third collector assembly 3 and the fourth collector assembly 4, the collector structure also includes a plurality of insulating ceramics 52 arranged along the inner wall of the outer cylinder 5, and the inner wall of the insulating ceramics 52 is provided with The limiting part 521 cooperates with the first collector assembly 1 , the second collector assembly 2 , the third collector assembly 3 and the fourth collector assembly 4 . The first collector assembly 1 , the second collector assembly 2 , the third collector assembly 3 and the fourth collector assembly 4 respectively have a first ...

Embodiment 2

[0076] The present invention also provides a traveling wave tube (not shown in the figure), which includes the collector structure described in Embodiment 1, and also includes an emitter structure, a radio frequency input structure, a radio frequency output structure, for connecting the emitter structure and the slow wave structure of the collector structure, and a tube body for accommodating the emitter structure, the collector structure, the radio frequency input structure, the radio frequency output structure and the slow wave structure;

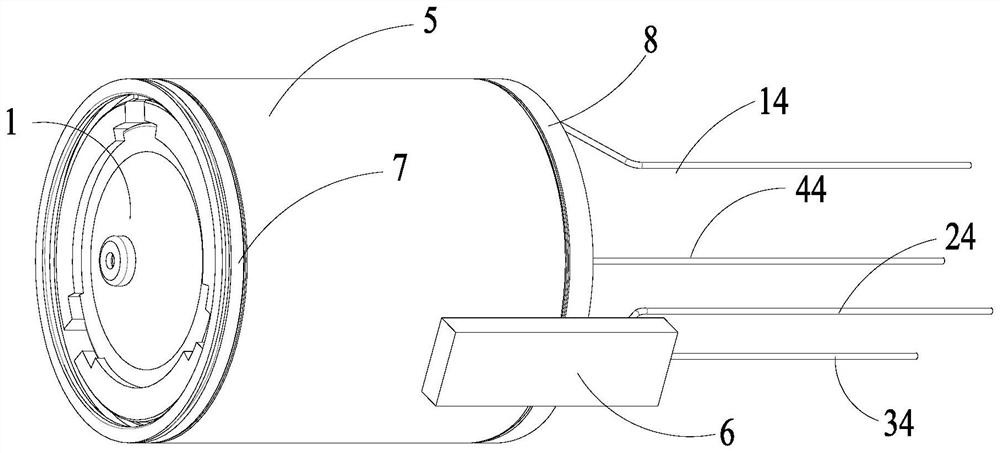

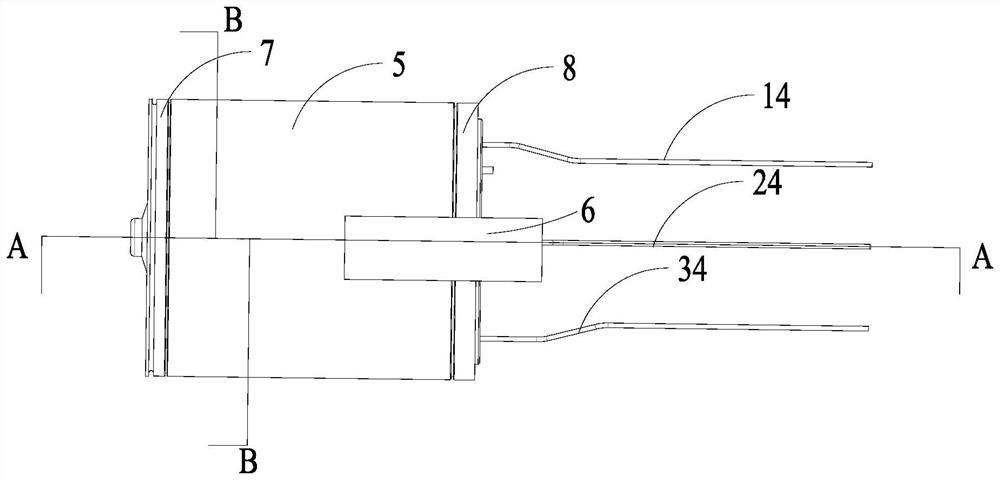

[0077] Among them, such as figure 1 , figure 2 As shown, the collector structure also includes a first sealing member 7 and a second sealing member 8 arranged at both ends of the outer cylinder 5, so as to realize the connection between the collector structure and the tube body and the slow wave structure. between the seals.

[0078] The places not mentioned in the present invention can be realized by adopting or referring to the prior...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com