Polyisocyanate composition and two-package type coating composition using the same

A technology of polyisocyanate and isocyanurate, applied in the field of polyisocyanate composition and two-component type coating composition, to achieve the effects of excellent recoatability, excellent solubility and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

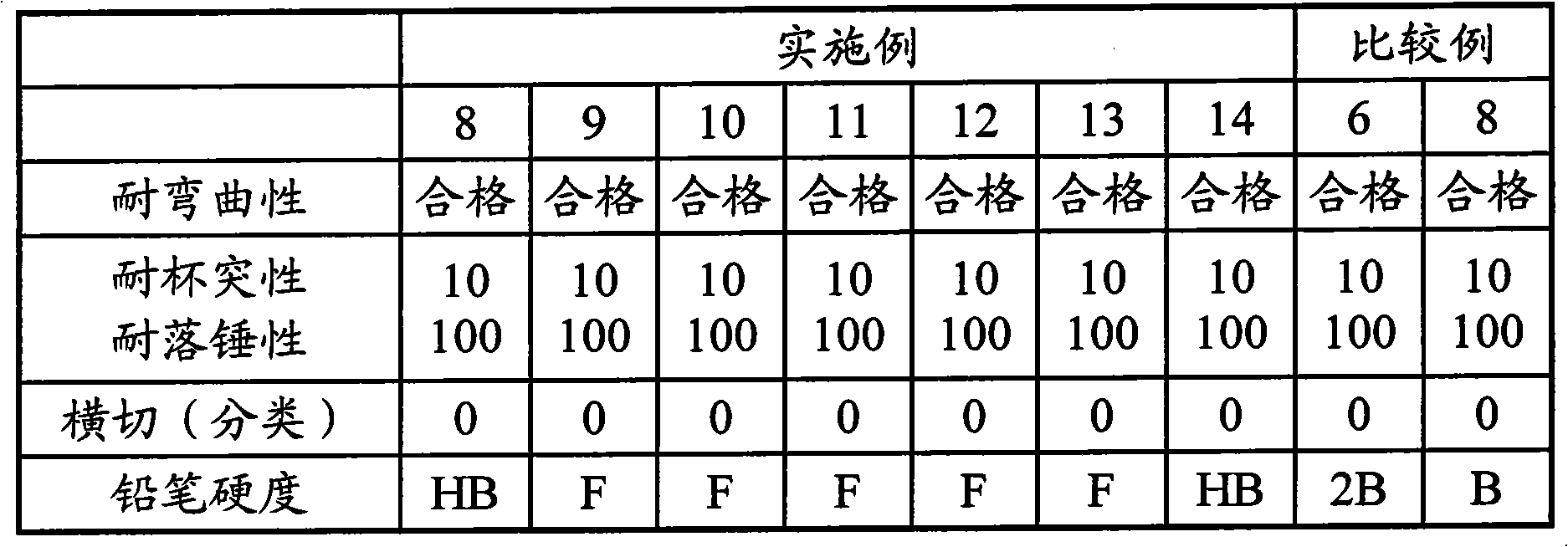

Examples

Embodiment 1

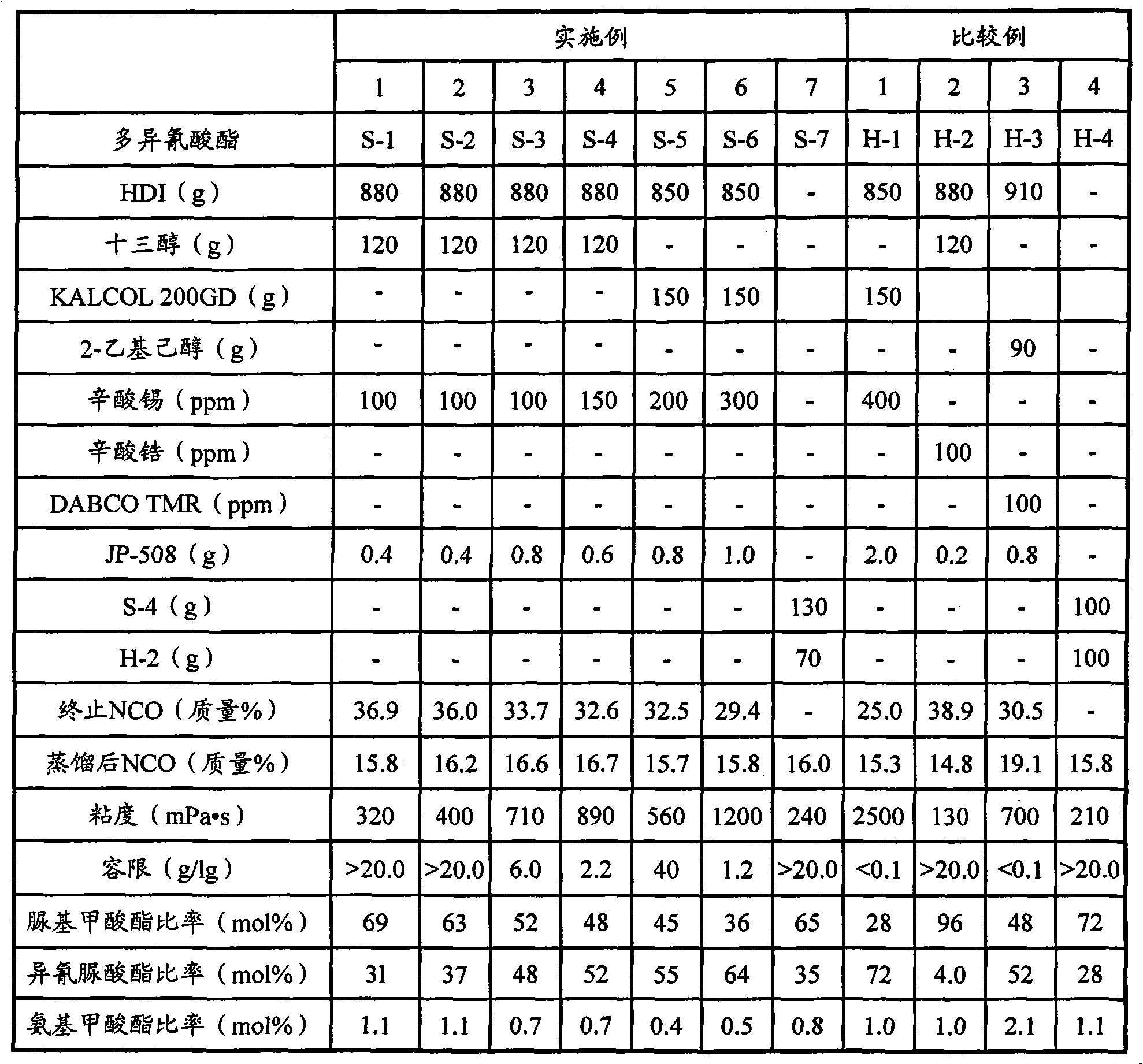

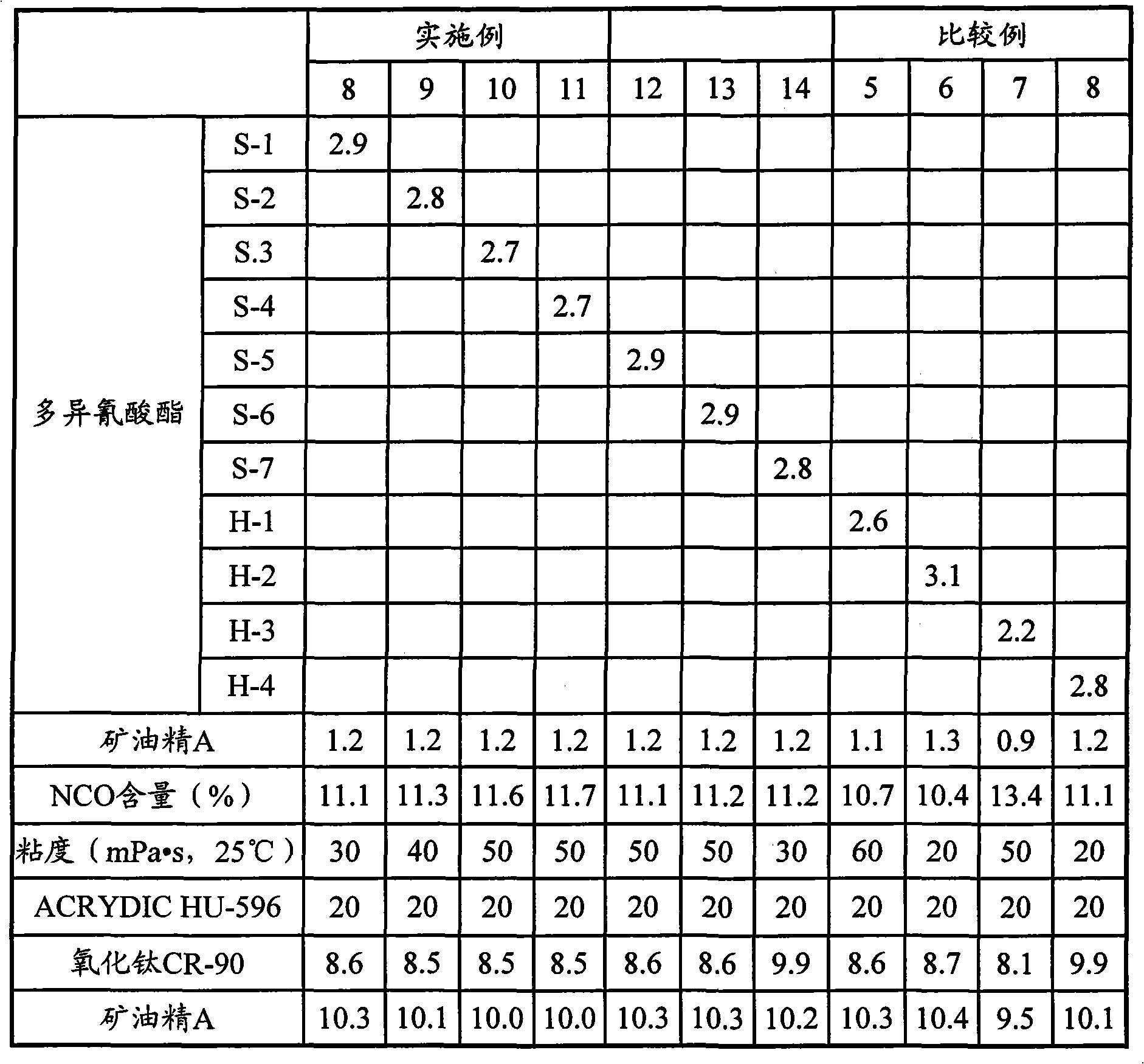

[0075] In a four-neck flask with a capacity of 1 liter equipped with a stirrer, a thermometer, a condenser tube, and a nitrogen gas introduction tube, 880 g of hexamethylene diisocyanate (manufactured by Nippon Polyurethane Industry Co., Ltd., NCO content: 49.9% by mass, hereinafter referred to as HDI ) and 120 g of tridecanol (manufactured by Kyowa Hakko Kogyo Co., Ltd.), were heated to 85° C. while stirring them, and a carbamate reaction was performed for 3 hours.

[0076] Thereafter, 0.1 g of tin octoate (manufactured by Nippon Kagaku Sangyo Co., Ltd.), which is a catalyst for allophanation and isocyanuration, was added to the reaction solution, and the reaction was carried out at 110° C. until the specified NCO content was reached. Then, 0.4 g of acid phosphate ester (JP-508, manufactured by Seonghoku Chemical Industry Co., Ltd.) as a reaction terminator was added, and the reaction was terminated at 50° C. for 1 hour.

[0077] The reaction product was removed by thin film ...

Embodiment 2~4

[0079] Modified polyisocyanates S-2 to S-4 were obtained in the same procedure as in Example 1 except that, as shown in Table 1, the charged amount of the catalyst and the like and the NCO content were changed.

Embodiment 5

[0081] In a four-neck flask with a capacity of 1 liter equipped with a stirrer, a thermometer, a condenser, and a nitrogen inlet pipe, 850 g of HDI (manufactured by Nippon Polyurethane Industry Co., Ltd., NCO content: 49.9% by mass) and 150 g of KALCOL 200GD (2-octyl Diodecanol, manufactured by Kao Co., Ltd.) was heated to 85° C. while stirring them, and a urethanization reaction was performed for 3 hours.

[0082] Thereafter, 0.2 g of tin octoate (manufactured by Nippon Kagaku Sangyo Co., Ltd.), which is a catalyst for allophanation and isocyanuration, was added to the reaction solution, and the reaction was carried out at 110° C. until a predetermined NCO content was reached. Then, 0.8 g of acid phosphate (JP-508, manufactured by Seonghoku Chemical Industry Co., Ltd.) as a reaction terminator was added, and the reaction was terminated at 50° C. for 1 hour.

[0083] The reaction product was removed by thin film distillation (conditions: 140°C, 0.04kPa) to remove excess HDI to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com