Highly crosslinkable low-viscosity polyisocyanate composition and coating composition containing same

A polyisocyanate and diisocyanate technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of limited use, low crosslinking, and increased monomer concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

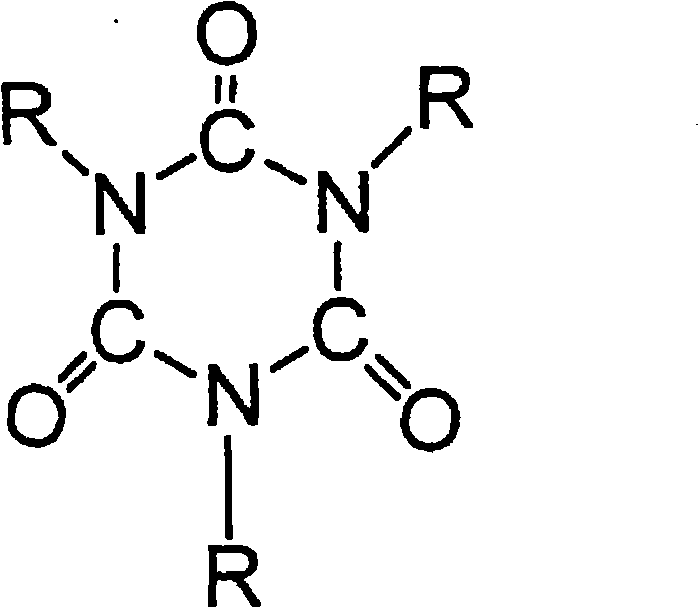

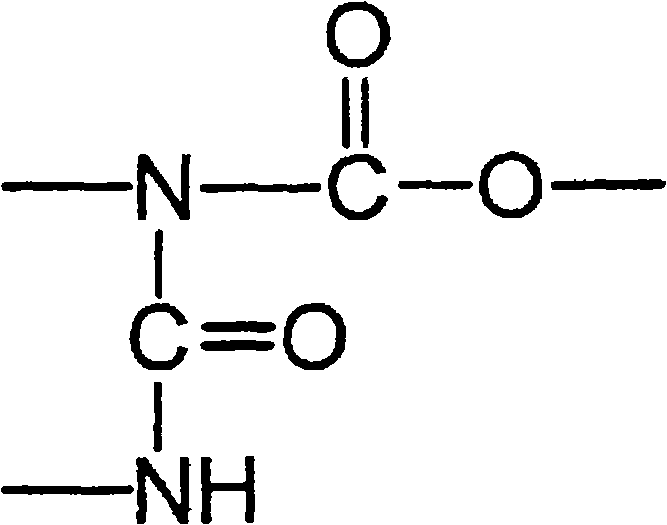

Method used

Image

Examples

Embodiment 1

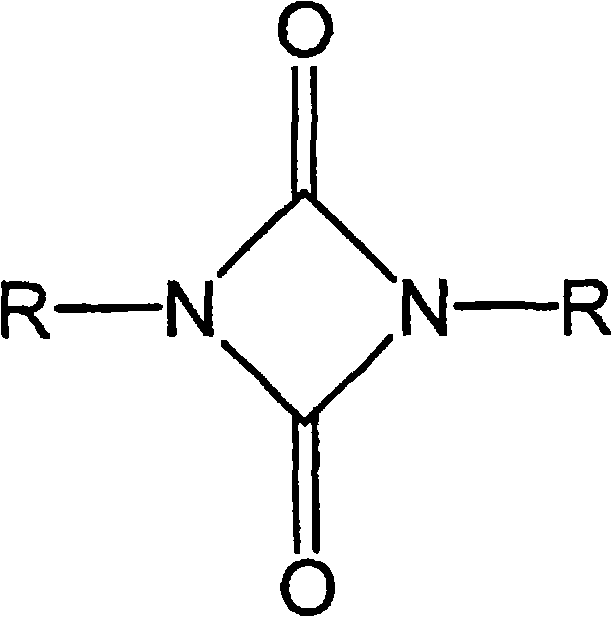

[0131] (Example 1) (manufacture of polyisocyanate composition)

[0132] Make the interior of the four-necked flask equipped with a stirrer, a thermometer, a reflux condenser, a nitrogen blowing tube, and a dropping funnel into a nitrogen atmosphere, and put in 600 parts of HDI and 0.6 parts of isobutanol, and keep the temperature in the reactor at 80 °C under stirring. 2 hours. After that, an isocyanurate catalyst tetramethylammonium caprate was added to carry out isocyanurate reaction, and when the conversion rate reached 20%, phosphoric acid was added to stop the reaction. The mass concentration of uretdione dimer increased in this reaction is below 1%. The reaction liquid was further kept at 160° C. for 1 hour. Polyisocyanate containing uretdione groups is produced by heating. The reaction solution was filtered after cooling, and then unreacted HDI was removed using a thin film evaporator. Table 1 shows the characteristics of the obtained polyisocyanate composition.

Embodiment 2

[0134] It carried out similarly to Example 1 except having set the conversion rate of the isocyanuration reaction to 13%. The results are shown in Table 1.

Embodiment 3

[0136] It carried out similarly to Example 1 except having set the conversion rate of the isocyanuration reaction to 8%. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com