Soft polyurethane foam and its manufacture method

A kind of soft polyurethane, the technology of manufacturing method, applied in the direction of packaged food, packaged item types, bandages, etc., can solve the problems of uneven pore state, discoloration, low reaction stability, etc., and achieve excellent discoloration resistance and good compression permanent deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

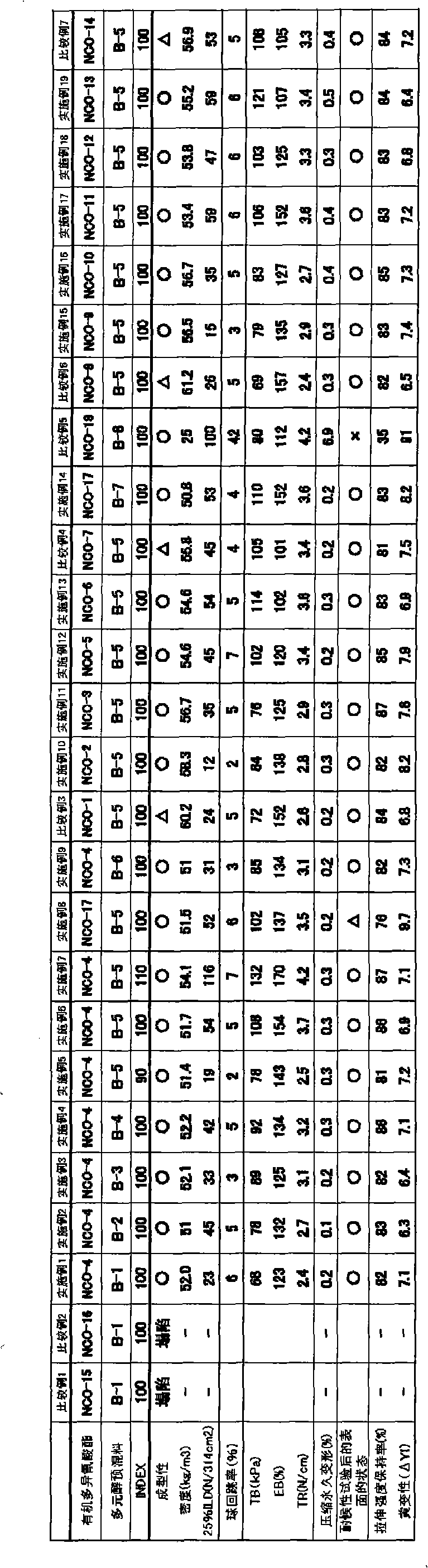

[0062] Hereinafter, specific examples of the present invention will be further described. Of course, the present invention is not limited to the examples.

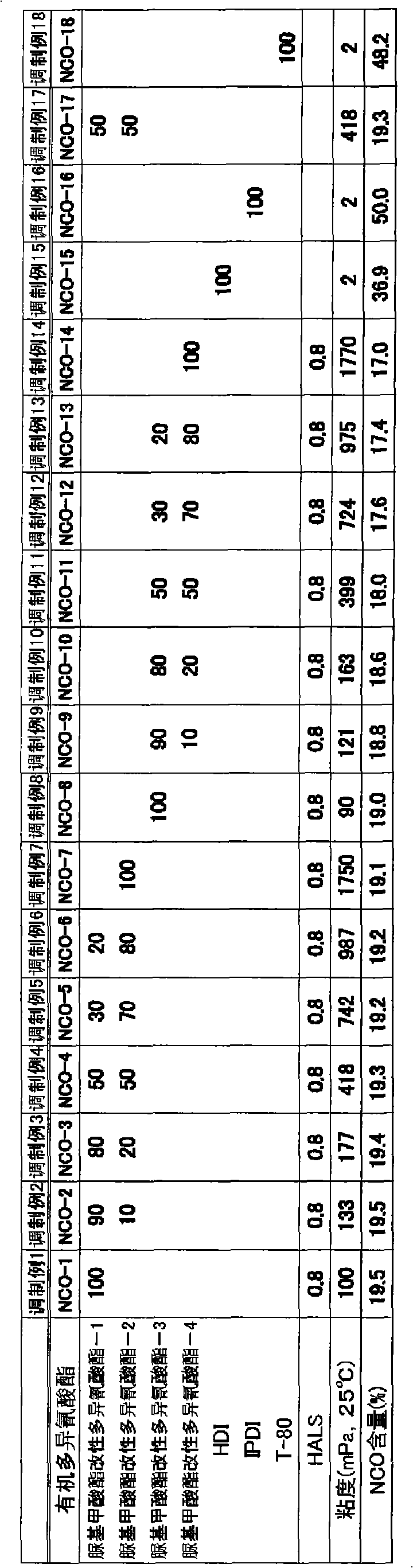

[0063] Manufacture of allophanate modified polyisocyanate

Synthetic example 1

[0065] Add 950 g of hexamethylene diisocyanate (HDI: manufactured by Nippon Polyurethane Industry Co., Ltd.) and 50 g of isopropanol to a reactor with a capacity of 1 L equipped with a stirrer, a thermometer, a cooler, and a nitrogen gas introduction pipe, and carry out the process at 90° C. for 2 hours. carbamate reaction. Analysis of the reaction product by FT-IR revealed that the hydroxyl group disappeared. Next, 0.1 g of zirconyl octoate (manufactured by Daiichi Zengen Chemical Industry Co., Ltd.) was added, and it was made to react at 90 degreeC for 3 hours. With FT-IR and 13C-NMR analysis of the reaction product revealed that the carbamate group disappeared. Next, 0.11 g of JP-508 (manufactured by Johoku Chemical Co., Ltd.) was added, and the reaction was stopped at 50° C. for 1 hour. The isocyanate content of the reaction product after stopping the reaction was 40.46%. The reaction product was subjected to thin-film distillation at 140°C and 40Pa to obtain a "stainl...

Synthetic example 2

[0067] Except adding 950g hexamethylene diisocyanate (HDI), 50g 3-methylpentanediol, by the same method as synthetic example 1, obtain " allophanate modified polyisocyanate-2 " (isocyanate content is 19.1%, the viscosity at 25°C is 1720mPa·s, the free hexamethylene diisocyanate is 0.1%, and the color index is 20APHA).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com