Method for recycling aniline in preparation process of diphenylmethane series diamine and polyamine

A diphenylmethane and preparation process technology, applied in the field of DAM preparation and separation, can solve the problems of hindering phase separation, unstable interface emulsification, etc., and achieve the effect of improving the interface emulsification problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

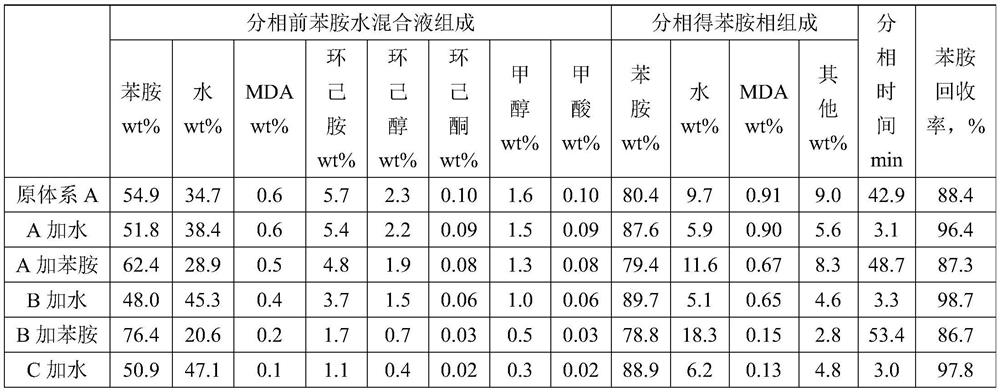

[0058] The phase separation process of aniline water during DAM preparation and DAM refining:

[0059] a) Aniline and hydrochloric acid are mixed in a static mixer to form aniline hydrochloride. The molar ratio of hydrochloric acid to aniline is 0.20, and then mixed with formaldehyde with a mass concentration of 37% and reacted at 60° C. for 30 minutes. The molar ratio of formaldehyde to aniline is 0.48, Obtain diamine and polyamine reaction solution containing diaminodiphenyl series;

[0060] b) Add 50wt% sodium hydroxide aqueous solution to the reaction solution in step a) according to 1.1 times the molar weight of hydrochloric acid for neutralization, carry out phase separation in a stratifier, and use 90°C hot pure water to neutralize the crude product after neutralization The amine organic phase is washed, and then the phases are separated again to obtain the refined polyamine organic phase comprising aniline and water after washing;

[0061] c) under the absolute pressu...

Embodiment 2

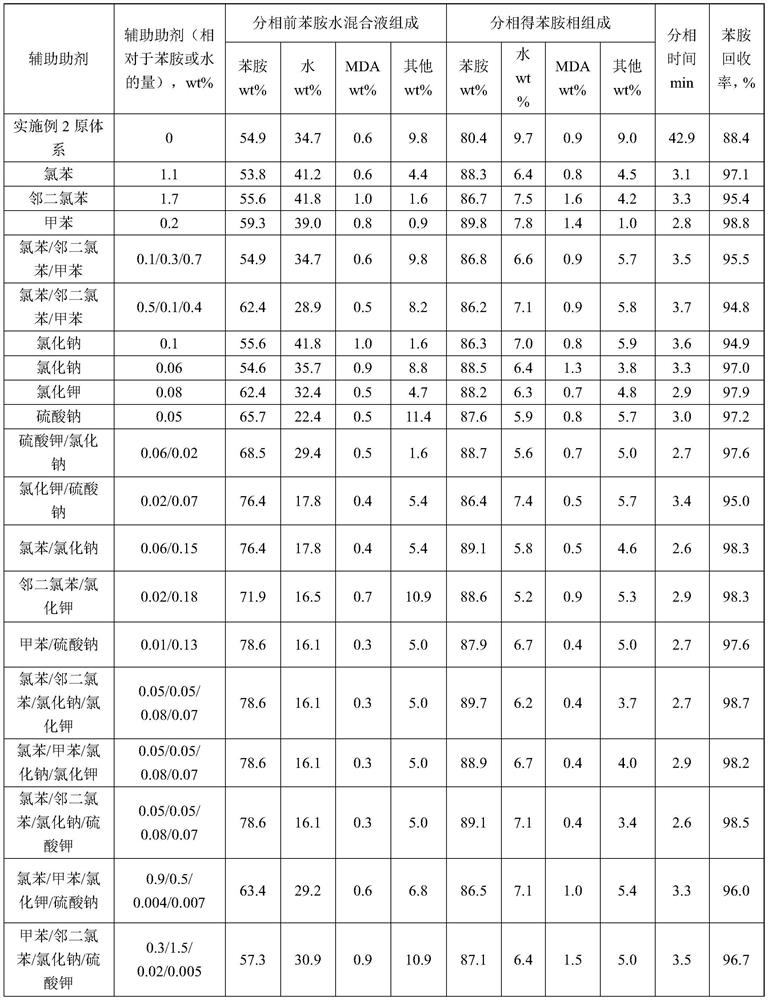

[0069] The phase separation process of aniline water during DAM preparation and DAM refining:

[0070] a) Aniline and hydrochloric acid are mixed in a static mixer to form aniline hydrochloride. The molar ratio of hydrochloric acid to aniline is 0.30, and then mixed with a 50% aqueous solution of formaldehyde at a mass concentration of 65°C for 40 minutes. The molar ratio of formaldehyde to aniline is 0.43 , to obtain diamine and polyamine reaction solutions containing diaminodiphenyl series;

[0071] b) Add 50wt% sodium hydroxide aqueous solution to the reaction solution in step a) according to 1.05 times the molar weight of hydrochloric acid for neutralization, carry out phase separation in a stratifier, and use 95°C hot pure water to neutralize the crude product after neutralization The amine organic phase is washed, and then the phases are separated again to obtain a refined polyamine organic phase comprising aniline and water;

[0072] c) stripping and distilling the ref...

Embodiment 3

[0085] The phase separation process of aniline water during DAM preparation and DAM refining:

[0086] a) Aniline and hydrochloric acid are mixed in a static mixer to form aniline hydrochloride. The molar ratio of hydrochloric acid to aniline is 0.30, and then mixed with a 50% aqueous solution of formaldehyde at a mass concentration of 65°C for 40 minutes. The molar ratio of formaldehyde to aniline is 0.38 , to obtain diamine and polyamine reaction solutions containing diaminodiphenyl series;

[0087] b) Add 50% sodium hydroxide solution to the reaction solution in step a) according to 1.15 times the molar weight of hydrochloric acid for neutralization, carry out phase separation in a stratifier, and use 85°C hot pure water to neutralize the crude product after neutralization The amine organic phase is washed, and then the phases are separated again to obtain a refined polyamine organic phase comprising aniline and water;

[0088] c) under the absolute pressure of 4kPa, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com