Method and device capable of preventing engine oil emulsification of gas engine

A gas engine and oil technology, applied in the direction of machine/engine, engine lubrication, mechanical equipment, etc., can solve problems such as oil whitening and engine oil water content exceeding the standard, reduce oil costs, solve oil emulsification, and ensure normal work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

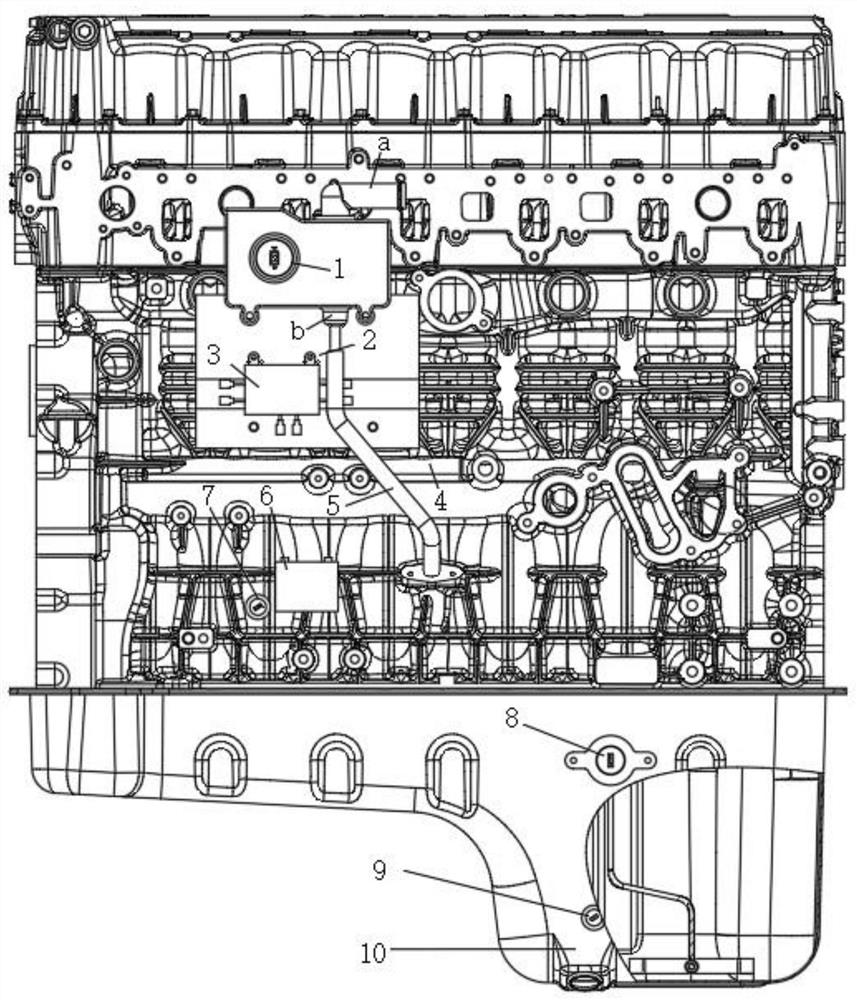

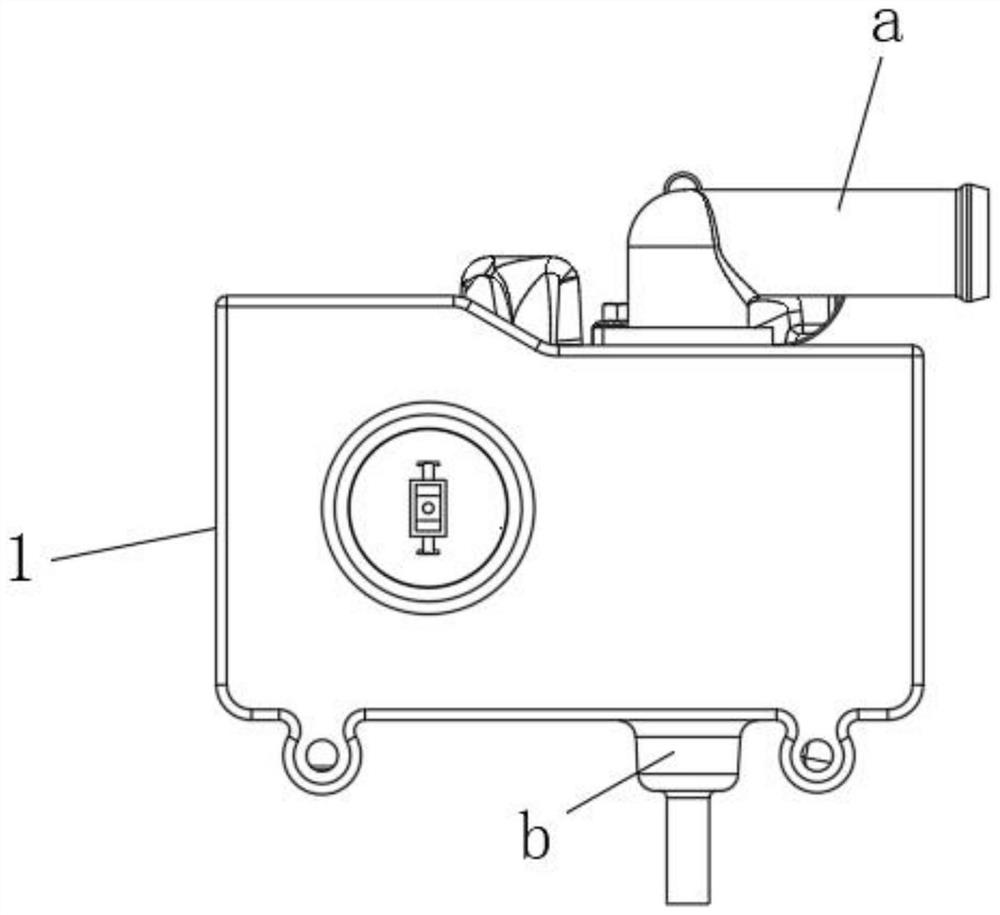

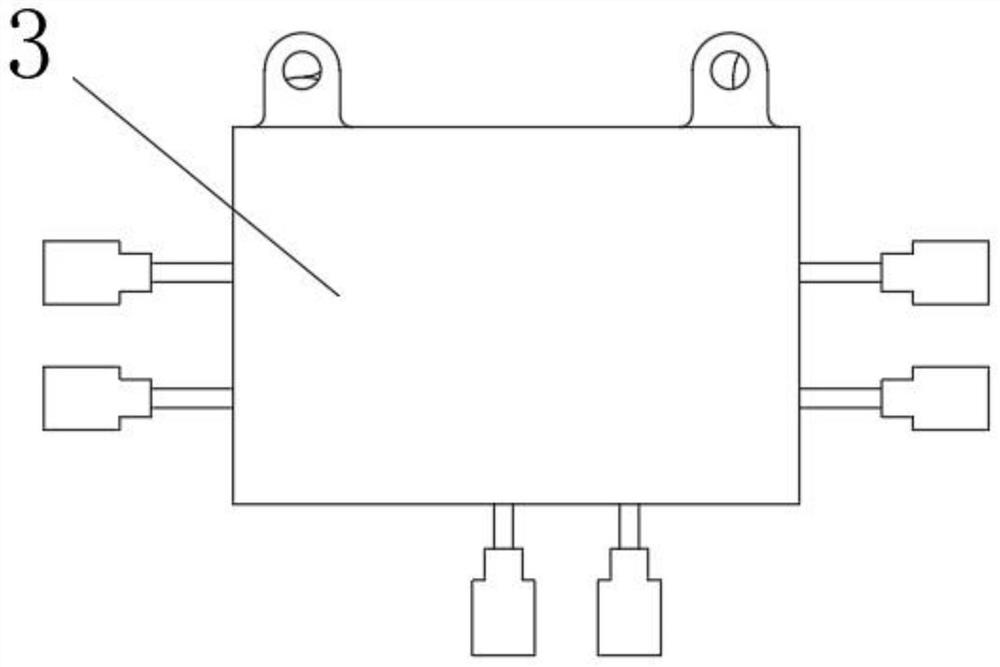

[0029] This embodiment provides a device that can prevent the emulsification of gas engine oil, such as Figure 1-5 As shown, it includes an electronically controlled oil-gas separation device 1, a connecting plate 2, an anti-high temperature protection and power-off device 3, a body 4, an oil return pipe 5, a power supply energy storage device 6, a pressure sensor 7, a heating device 8, a temperature sensor 9 and oil Bottom shell 10, wherein, the electronically controlled oil-gas separation device 1 and the high temperature protection and power-off device 3 are all installed on the connecting plate 2, and the connecting plate 2 and the pressure sensor 7 are all installed on the body 4;

[0030] The oil return pipe 5 and the electronically controlled oil-gas separation device 1 are all connected to the body 4;

[0031] The anti-high temperature protection and power-off device 3 is connected with the heating device 8 through wires;

[0032] The oil pan 10 is installed below th...

Embodiment 2

[0041] This embodiment provides a method that can prevent the emulsification of gas engine oil, and the specific steps are as follows:

[0042] S1. The system pre-designs the working procedure of the electronically controlled oil-gas separation device 1;

[0043] S2. The electronically controlled oil-gas separation device 1 is activated to quickly discharge the water vapor inside the engine to the outside of the crankcase;

[0044] S3. When the pressure sensor 7 senses that the crankcase pressure reaches -2Kpa, the electronically controlled oil-gas separation device 1 stops, and when the pressure rises, the electronically controlled oil-gas separator 1 starts working again until the 3-minute auxiliary exhaust work is completed;

[0045] S4. When the engine stops working, due to the delayed work setting of the system, the electronically controlled oil-gas separation device 1 will continue to work for 3 minutes until the residual gas inside the crankcase is emptied, and the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com