Preprocessing Method for GC-MS (Gas Chromatography-Mass Spectromete) analysis of essence and spice

A GC-MS, flavor and fragrance technology, applied in the direction of material separation, analysis of materials, preparation of test samples, etc., can solve problems such as emulsification, insufficient extraction, and inaccurate analysis and quantification of flavor and fragrance components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example description: first add nicotine to the easily emulsifiable flavor and fragrance A. Configured as a 50ppm solution.

[0013] Test one:

[0014] 1) Weigh 0.3g of flavor and fragrance A for use (accurate to 0.0001g). Add 10ml of purified water to the weighed Class A flavor and fragrance, shake and shake evenly.

[0015] 2) Prepare to add 5 ml of dichloromethane containing an internal standard (using phenylpropyl propionate as the internal standard solution, concentration less than 0.1 mg / ml) to it. 150HZ, shake for 30min, make it fully contact with the extraction.

[0016] 3) After shaking, centrifuge at 3000 rpm for 5 minutes, and remove the supernatant.

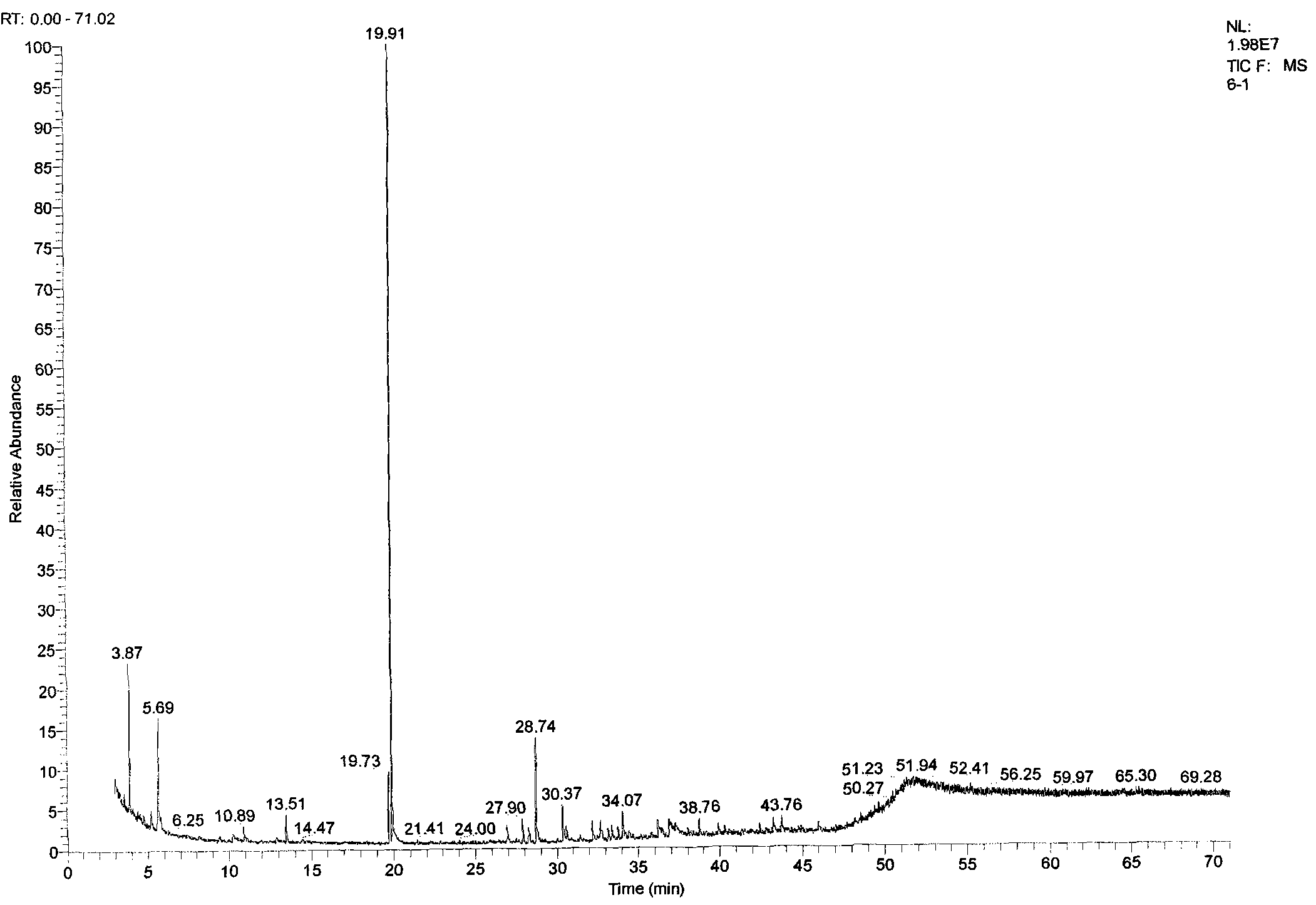

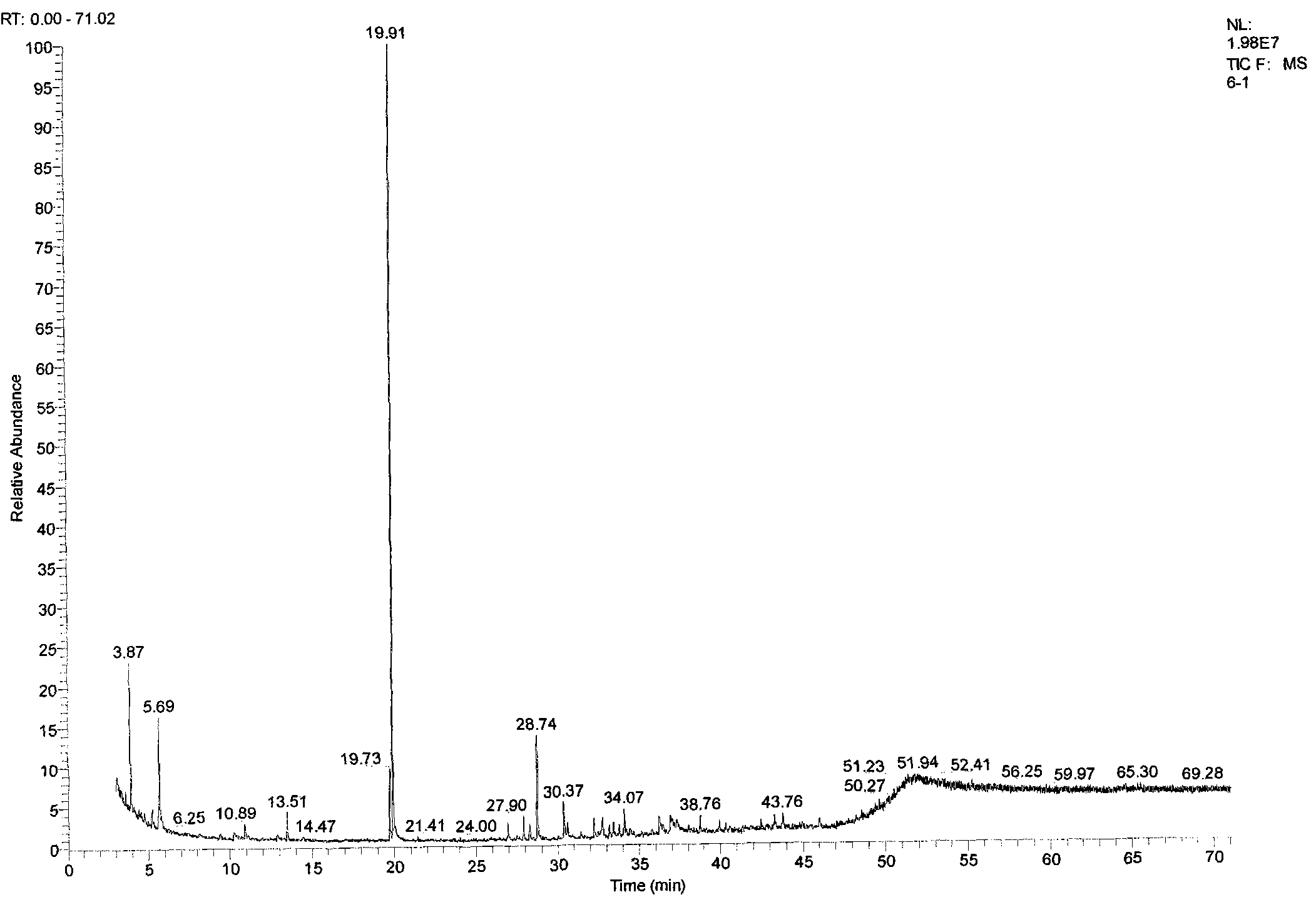

[0017] Enter GC-MS for component analysis, and make double samples of the samples, the obtained picture is as follows figure 1 , figure 2 shown. The relative error between the obtained nicotine and the added real value reaches 22.57% through quantitative calculation

Embodiment 2

[0019] 1) Weigh about 0.1 g of internal standard phenylpropyl propionate. Dissolve the weighed internal standard in dichloromethane, and adjust the volume to 1 L. Equipped with a 100ppm internal standard solution.

[0020] 2) Weigh 0.3g of flavor and fragrance A for use (accurate to 0.0001g). Add 10ml of purified water to the weighed Class A flavor and fragrance, shake and shake evenly to obtain the flavor and fragrance solution.

[0021] 3) Add 5ml of internal standard solution to the obtained essence and fragrance solution, shake at 150HZ for 30min, and make it fully contact with extraction.

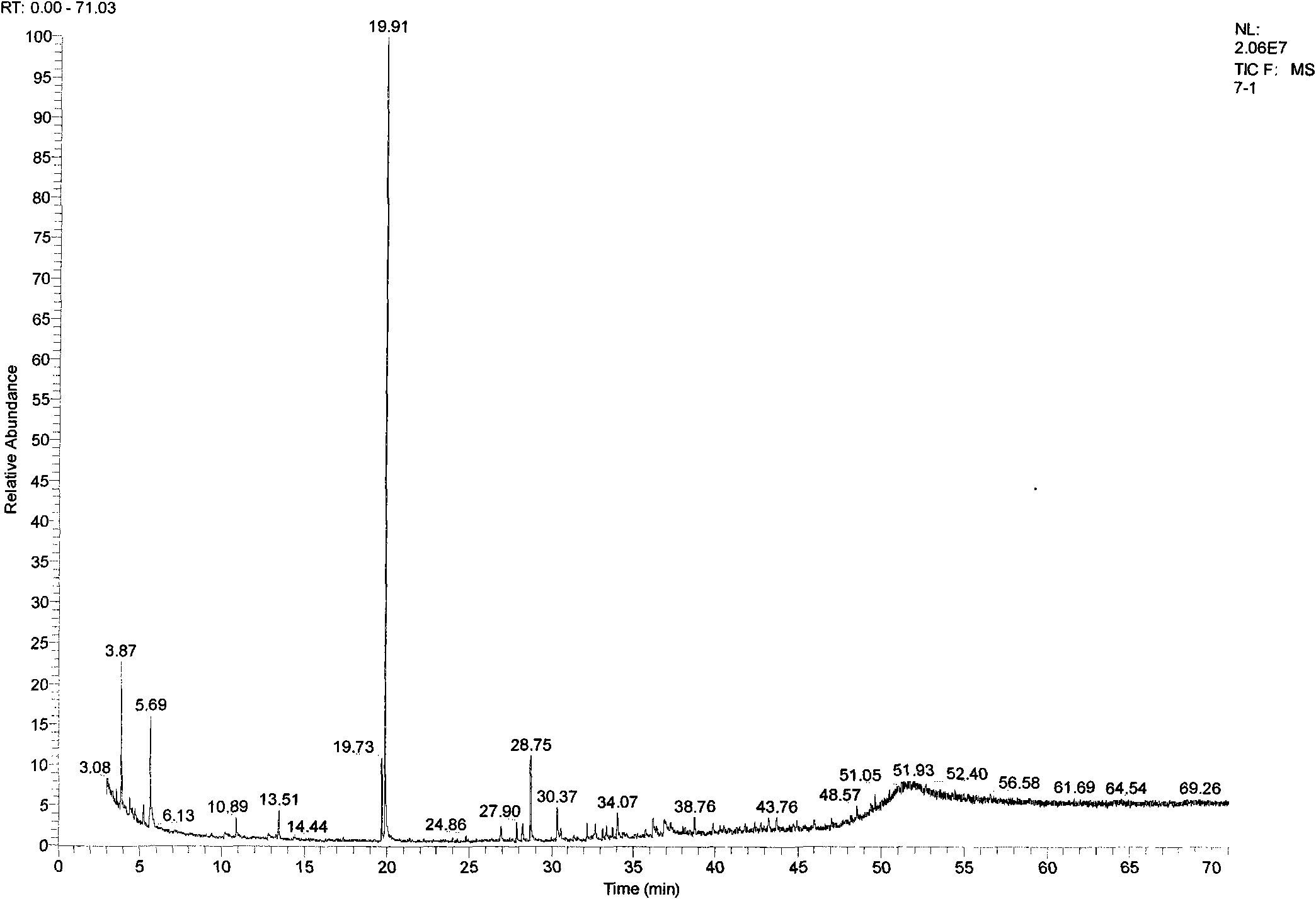

[0022] 4) After oscillating, centrifuge at 3000rpm for 5min, carry out microwave digestion on the obtained centrifugate to remove the emulsification phenomenon produced by dichloromethane and flavors and fragrances, and take off the supernatant to analyze the obtained solution by GC-MS. Such as image 3 , Figure 4 shown. The relative error between the obtained nicotine and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com