Novel process for treating maleic anhydride wastewater

A technology for wastewater treatment and new process, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Reliable, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

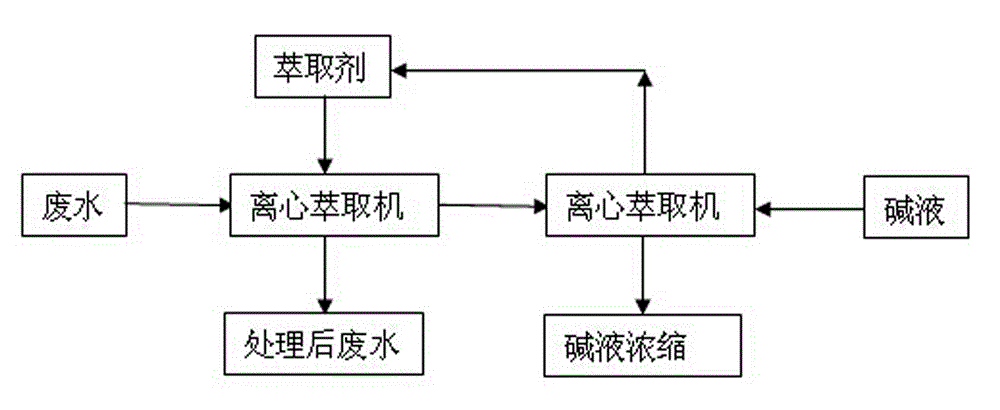

[0020] The process flow diagram is as follows figure 1 As shown, a new process for maleic anhydride wastewater treatment, comprising the following steps:

[0021] 1) The wastewater from the maleic anhydride workshop first passes through the grease trap to remove most of the floating oil;

[0022] 2) The waste water after oil separation passes through the waste water pump at a distance of 12m 3 The flow rate of / h enters the centrifugal extractor, turn on the extractant pump, set the flow rate of the extractant and the waste water to enter the centrifugal extractor at the same time according to the flow ratio of wastewater to extractant of 10:1, and set the frequency of the centrifugal extractor to 30Hz; the extractant used is : N,N-bis(1-methylhexyl)hexamide;

[0023] 3) The treated wastewater from the heavy phase outlet of the centrifugal extractor can be discharged up to the standard after further aerobic biological treatment;

[0024] 4) The extract from the light phase ...

Embodiment 2

[0026] The process flow diagram is as follows figure 1 As shown, a new process for maleic anhydride wastewater treatment, comprising the following steps:

[0027] 1) The wastewater from the maleic anhydride workshop first passes through the grease trap to remove most of the floating oil;

[0028] 2) The waste water after oil separation passes through the waste water pump at a distance of 15m 3 The flow rate of / h enters the centrifugal extractor, turn on the extractant pump, set the flow rate of the extractant and the waste water to enter the centrifugal extractor at the same time according to the flow ratio of wastewater to extractant of 15:1, and set the frequency of the centrifugal extractor to 35Hz; the extractant used is : P204;

[0029] 3) The treated wastewater from the heavy phase outlet of the centrifugal extractor can be discharged up to the standard after further aerobic biological treatment;

[0030] 4) The extract from the light phase outlet of the centrifugal ...

Embodiment 3

[0032] The process flow diagram is as follows figure 1 As shown, a new process for maleic anhydride wastewater treatment, comprising the following steps:

[0033] 1) The wastewater from the maleic anhydride workshop first passes through the grease trap to remove most of the floating oil;

[0034] 2) The waste water after oil separation passes through the waste water pump at a distance of 18m 3 The flow rate of / h enters the centrifugal extractor, turn on the extractant pump, set the flow rate of the extractant and the waste water to enter the centrifugal extractor at the same time according to the flow ratio of wastewater to extractant of 18:1, and set the frequency of the centrifugal extractor to 37Hz; the extractant used is : sec-octanol;

[0035] 3) The treated wastewater from the heavy phase outlet of the centrifugal extractor can be discharged up to the standard after further aerobic biological treatment;

[0036] 4) The extract from the light phase outlet of the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com