Recycling method of organic phase used for extracting scandium

An organic phase and extraction technology, which is applied in the field of organic phase recycling, can solve the problems of low organic phase extraction efficiency, difficult process operation, and increased production costs, so as to achieve rapid phase separation, reasonably protect the environment, and increase production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Preparation of the organic phase treated with sodium sulfide solution

[0023] 1. Sodium sulfide solution

[0024] The solid sodium sulfide and distilled water were prepared into a 0.3% sodium sulfide solution by weight.

[0025] 2. Organic phase

[0026] The organic phase contains the extractant P204, ie, bis(2-ethylhexylphosphoric acid), and the diluent kerosene, wherein the volume ratio of P204 and kerosene is 1:5. After the organic phase is used to extract scandium from titanium dioxide wastewater, in addition to the extracted scandium, the organic phase also contains other impurities. The organic phase to be treated is alkaline, for example with a pH of 8.0, and in addition, the ventilation effect of the operating environment is maintained.

[0027] Through the above operations, it can be avoided that the sodium sulfide solution combines with hydrogen ions to form hydrogen sulfide gas after being added to the organic phase, thereby causing harm to the...

Embodiment 2

[0030] Example 2: Preparation of the organic phase treated with sodium sulfide solution

[0031] 1. Sodium sulfide solution

[0032] Collect the used sodium sulfide waste water in Example 1, after aging, namely under room temperature conditions, the sodium sulfide waste water is left standstill for 24 hours, get the supernatant, add an appropriate amount of sodium sulfide solid, and be made into a 1.0% by weight sodium sulfide solution .

[0033] 2. Organic phase

[0034] The organic phase contains the extractant P204, ie, bis(2-ethylhexylphosphoric acid), and the diluent kerosene, wherein the volume ratio of P204 and kerosene is 1:5. After the organic phase is used to extract scandium from titanium dioxide waste water, the aqueous phase is discharged, the organic phase is collected, and the organic phase to be treated is adjusted to alkaline, for example, the pH value is 9.0.

[0035] 3. Utilize the above-mentioned sodium sulfide solution to purify the organic phase to be ...

Embodiment 3

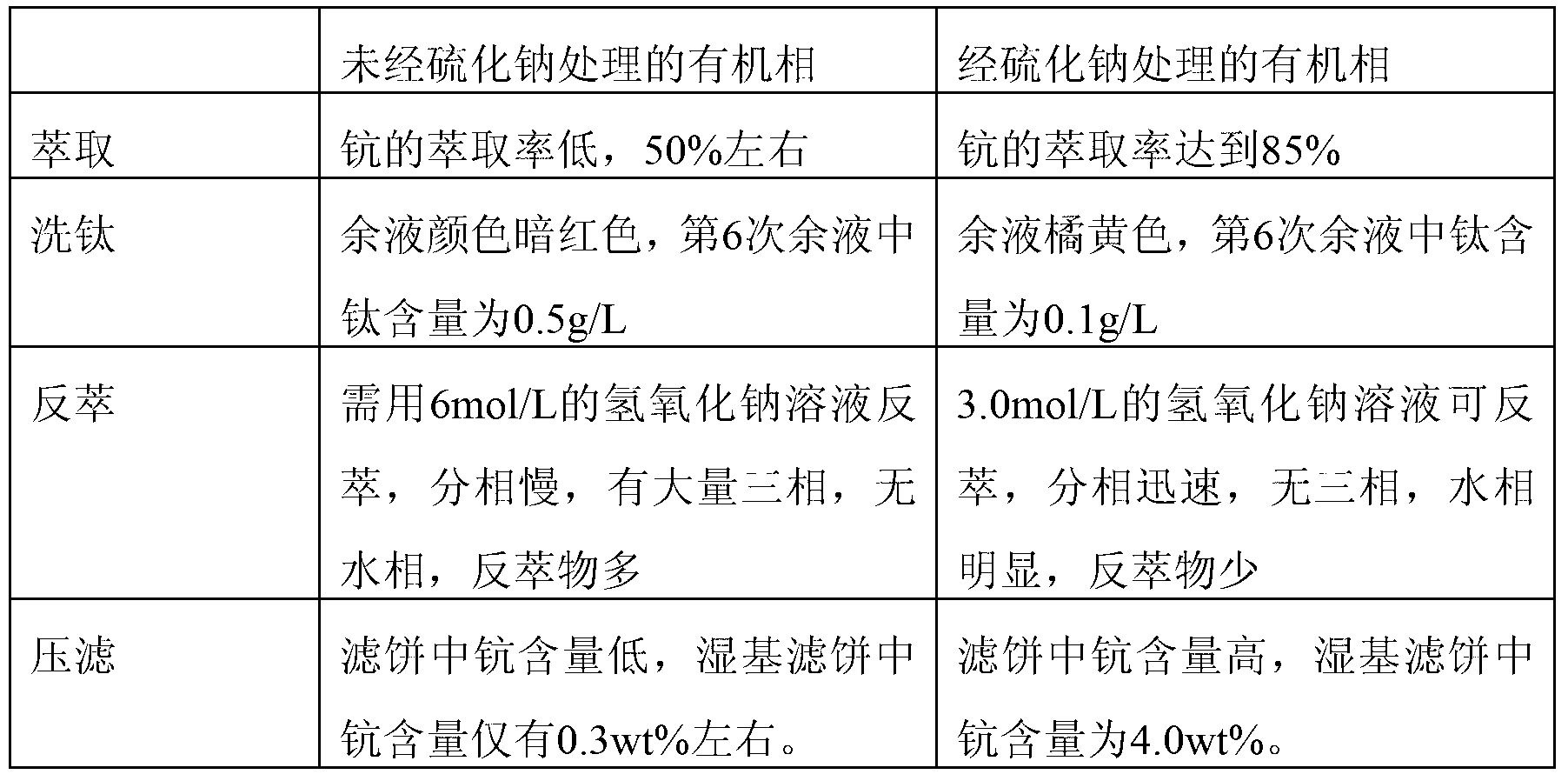

[0037] Example 3: Comparative study of using the organic phase obtained in Examples 1 and 2 and the organic phase without sodium sulfide treatment, acidification, and water washing in the process for recovering scandium from titanium dioxide wastewater

[0038] By comparing and studying the effects of the organic phases treated with sodium sulfide and those not treated with sodium sulfide in the whole process of extraction→washing titanium→back extraction→filtering by pressure, the extraction rate of different organic phases relative to scandium was analyzed, and the extraction rate of different organic phases relative to scandium was analyzed. effect, stripping effect, and the difference in scandium content in the filter cake after pressure filtration.

[0039] Wherein: in the extraction process, according to conventional operations, an organic phase, such as P204 and kerosene, is used to extract scandium in the titanium dioxide wastewater to obtain an aqueous phase and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com