Treatment method of high-concentration phenolic wastewater generated in lignite upgrading process

A treatment method, the technology of phenol wastewater, applied in the direction of extraction water/sewage treatment, etc., can solve the problems of high treatment cost, high incineration temperature requirements, low organic matter content in water, etc., and achieve the effect of enhancing the extraction effect and improving the extraction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

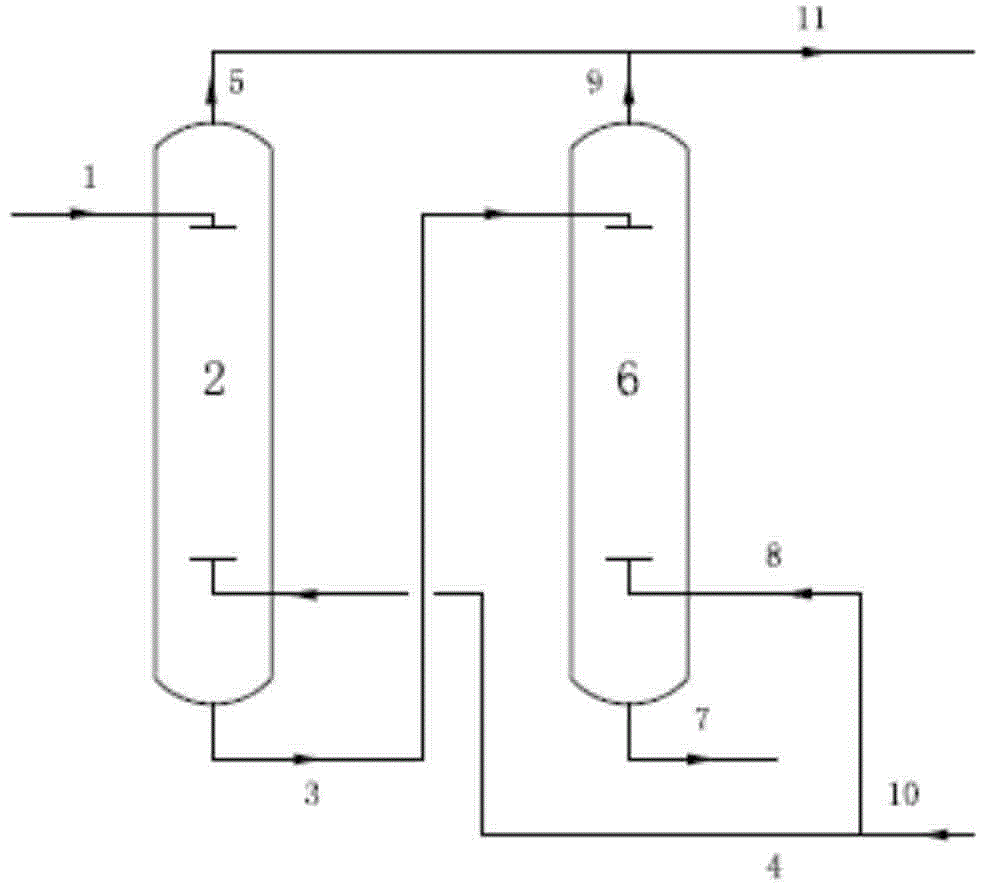

[0027] Four extraction towers are connected to process the high-concentration phenol-containing wastewater produced during the lignite upgrading process. The extraction stages of each extraction tower are 5, using methyl isobutyl ketone as the extraction agent, and the extraction temperature is 40°C. Each extraction tower The volume ratio of the extraction agent to the high-concentration phenol-containing wastewater is 1:3, and the specific process is:

[0028] The high-concentration phenol-containing wastewater after deacidification and deamination enters from the upper part of the first extraction tower, the first extraction agent enters from the bottom of the first extraction tower, and the high-concentration phenol-containing wastewater passes through the first extraction tower and the first extraction The waste water and extract I after the first extraction are obtained after continuous countercurrent extraction with the agent; the waste water after the first extraction co...

Embodiment 2

[0031]Two extraction towers are connected to process the high-concentration phenol-containing wastewater produced during the lignite upgrading process. The extraction stages of each extraction tower are 5, and methyl isobutyl ketone is used as the extraction agent. The extraction temperature is 65°C. Each extraction tower The volume ratio of the extraction agent to the high-concentration phenol-containing wastewater is 1:4, and the specific process is:

[0032] The high-concentration phenol-containing wastewater after deacidification and deamination enters the first extraction tower from the upper part of the first extraction tower, and is countercurrently extracted with the first extractant that enters from the bottom of the first extraction tower in the first extraction tower to obtain a The waste water and extract I; The waste water after the extraction from the first extraction tower still enters the second extraction tower from the second extraction tower top, and the seco...

Embodiment 3

[0035] Two extraction towers are connected to process the high-concentration phenol-containing wastewater generated during lignite upgrading. The volume ratio of the extraction agent of the tower to the high-concentration phenol-containing wastewater is 1:4, and the specific process is as follows:

[0036] The high-concentration phenol-containing wastewater after deacidification and deamination enters the first extraction tower from the upper part of the first extraction tower, and is countercurrently extracted with the first extractant that enters from the bottom of the first extraction tower in the first extraction tower to obtain a The waste water and extract I; The waste water after the extraction from the first extraction tower still enters the second extraction tower from the second extraction tower top, and the second extractant that enters from the second extraction tower still Countercurrent extraction is carried out in the second extraction tower to obtain dephenoliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com