Pressing solvent extraction device for absorbing extracting solvent under negative pressure

A technology for extracting solvent and pressurizing solvent, applied in the field of solvent extraction samples, can solve the problems of reduced extraction repeatability and poor wettability, and achieve the effects of improving extraction performance, avoiding secondary pollution and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

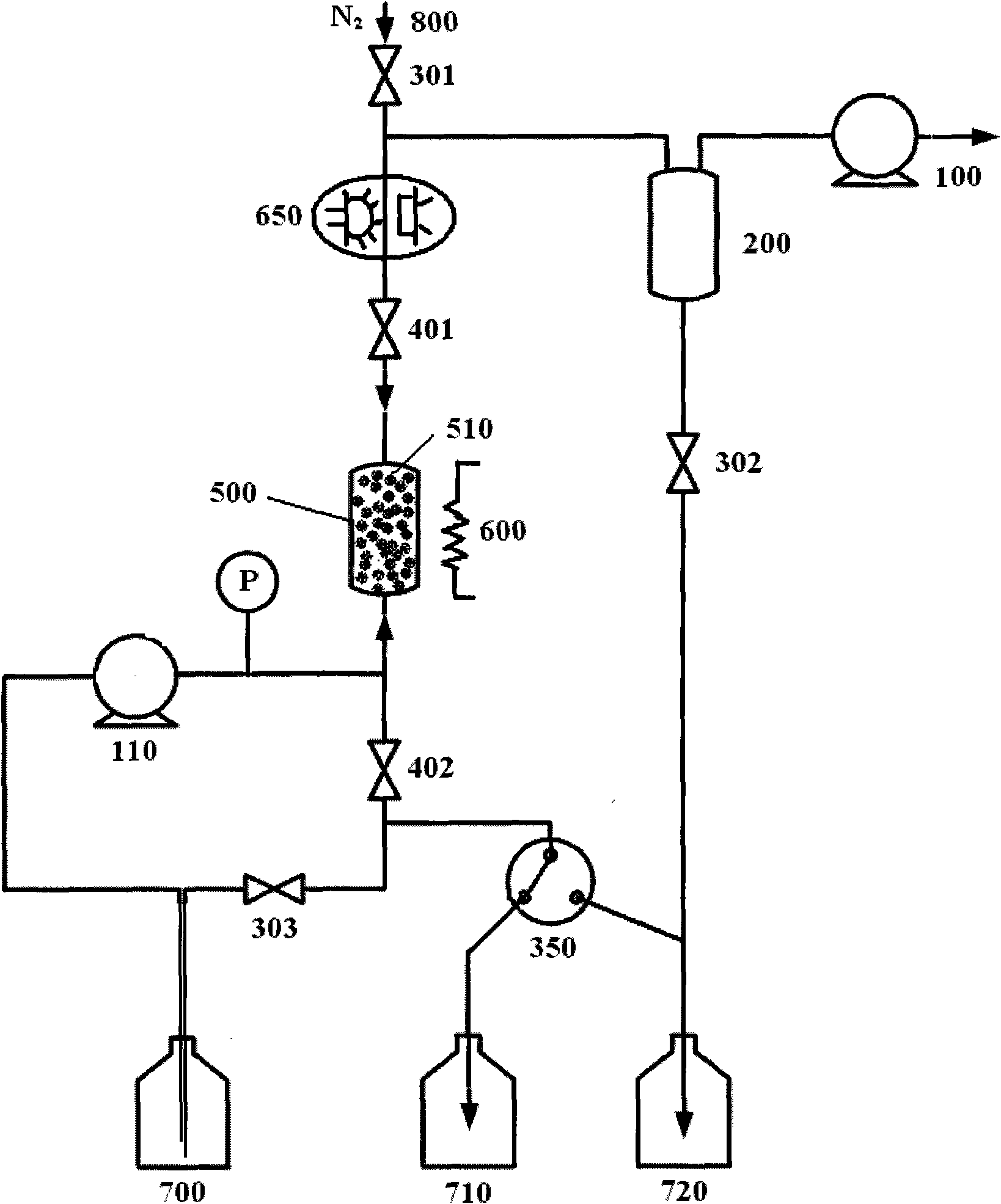

[0025] Such as Figure 1 Shown is a pressurized solvent extraction device for inhaling extraction solvent under negative pressure. The device includes an air pump 100, a high-pressure infusion pump 110, a buffer container 200, a flow switching valve 350, an extraction pool 500, an extraction pool heater 600, and a liquid sensor. 650, extraction solvent 700, extraction liquid collection bottle 710, waste liquid collection bottle 720 and auxiliary carrier gas 800;

[0026] An extraction pool heater 600 is arranged on the outer wall of the extraction pool 500;

[0027] The upper end of the extraction pool 500 is connected to the buffer container 200 through a pipeline, and the first high-pressure switch valve and the liquid sensor 650 are arranged in turn on their connecting pipeline, and the buffer container 200 is connected to the gas inlet of the air pump 100 through a pipeline; the buffer container The lower end of 200 is connected to the waste liquid collection bottle 720 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com