Patents

Literature

39results about How to "Good extraction performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device And Method For Extracting Active Principles From Natural Sources, Using A Counter-Flow Extractor Assited By A Sound Transduction System

InactiveUS20130197216A1Improve the extraction effectImprove performanceSugar derivativesMechanical vibrations separationNatural sourceCounter flow

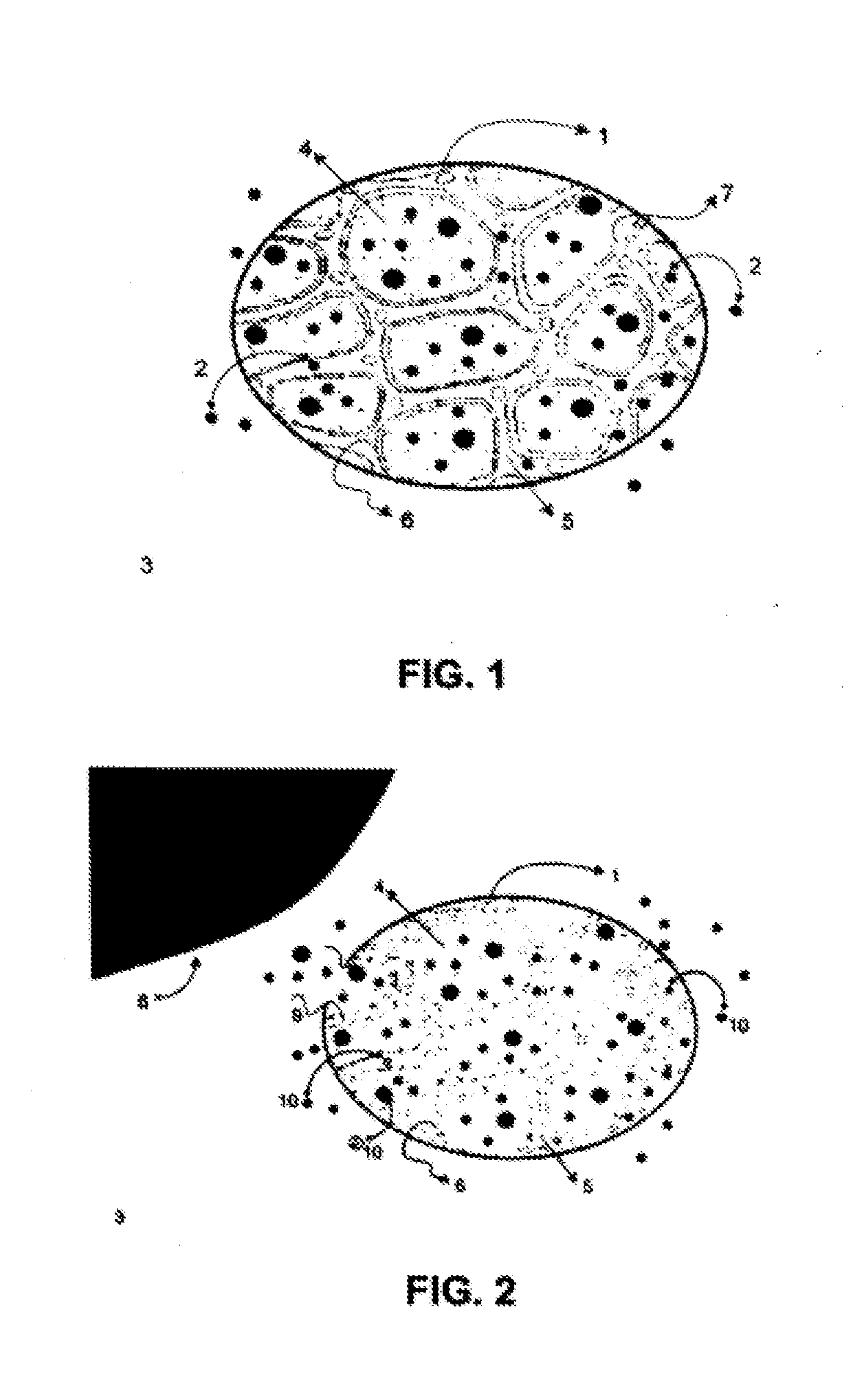

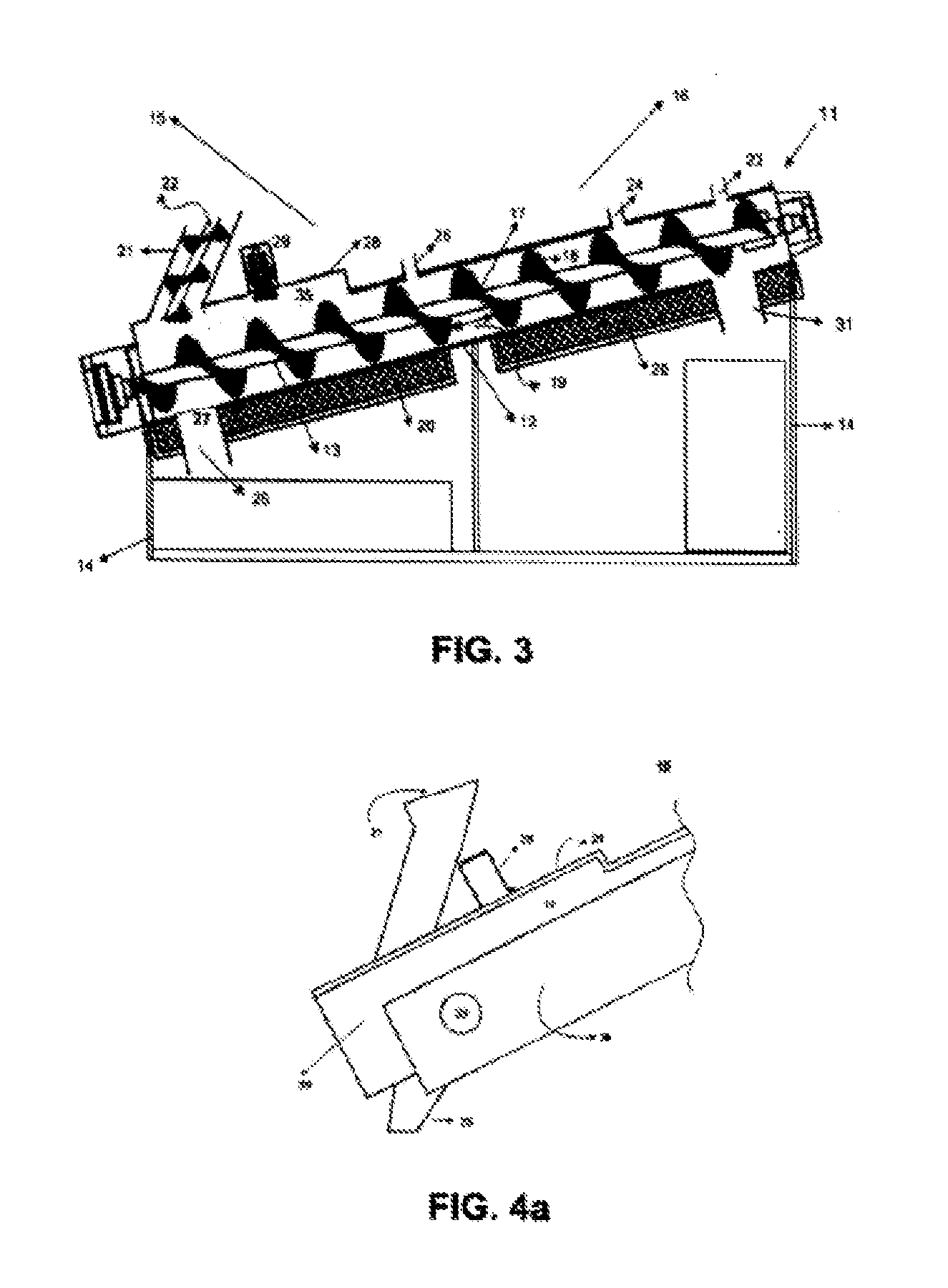

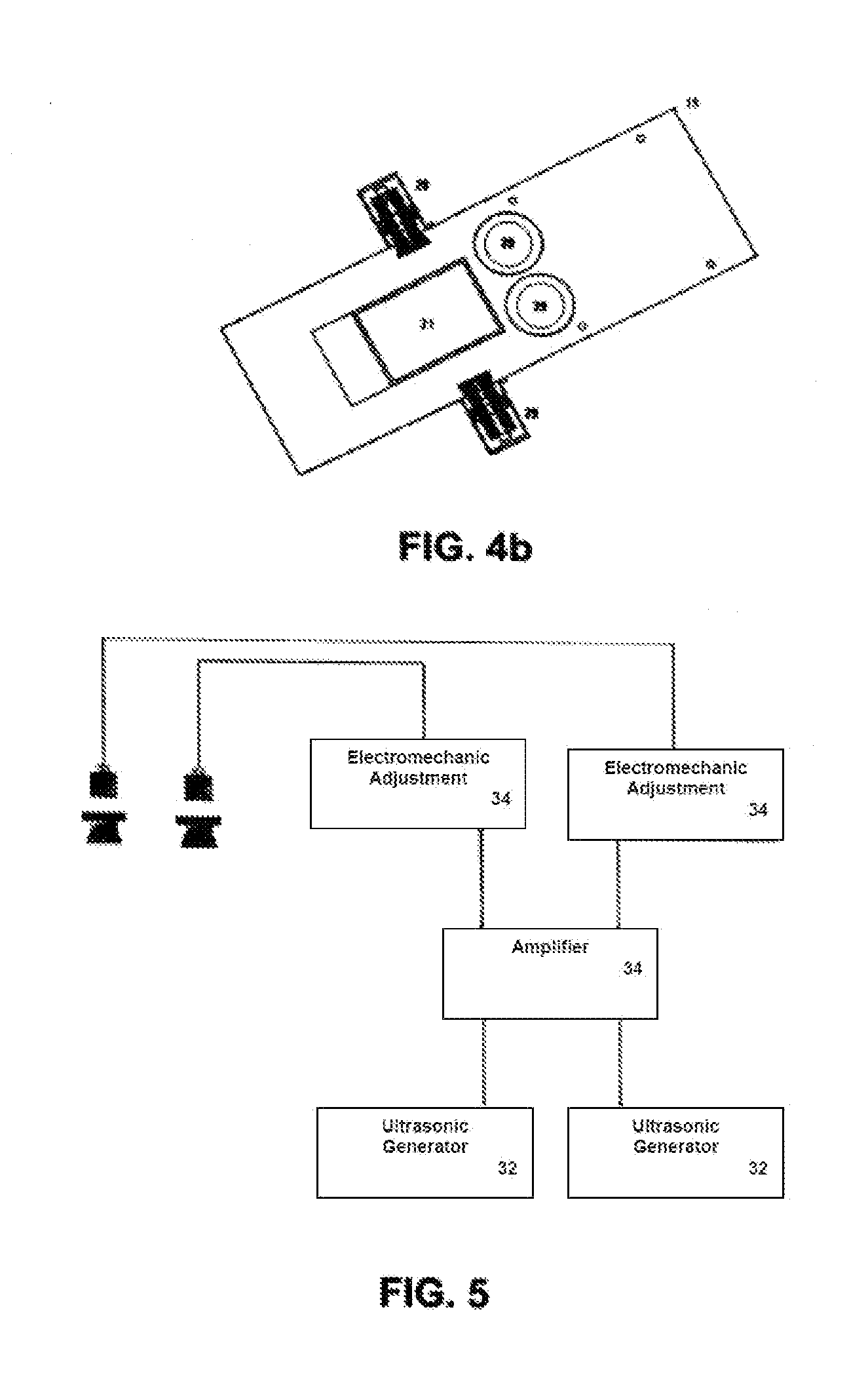

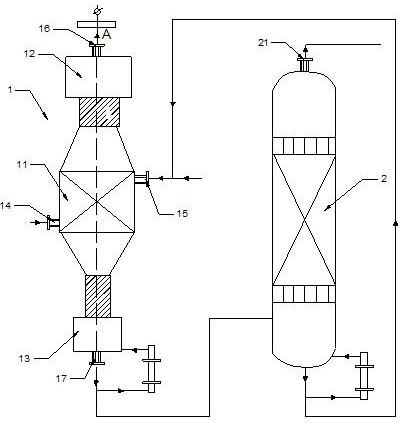

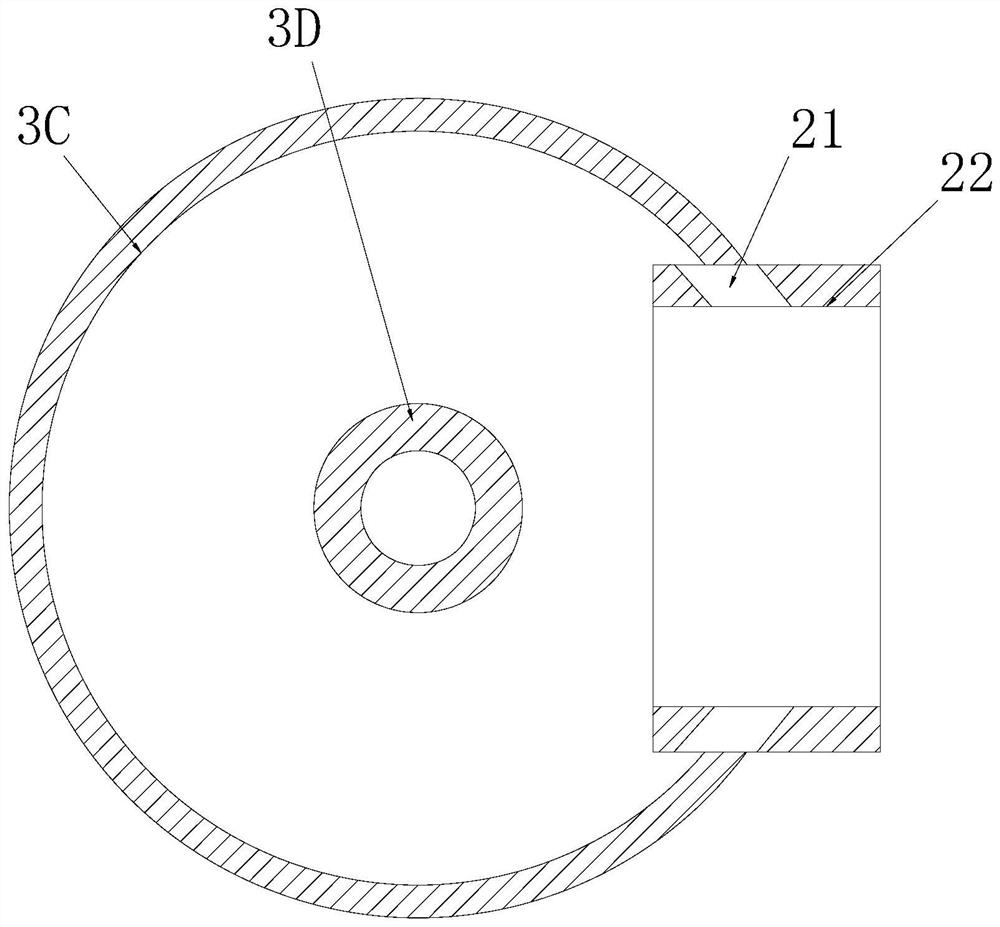

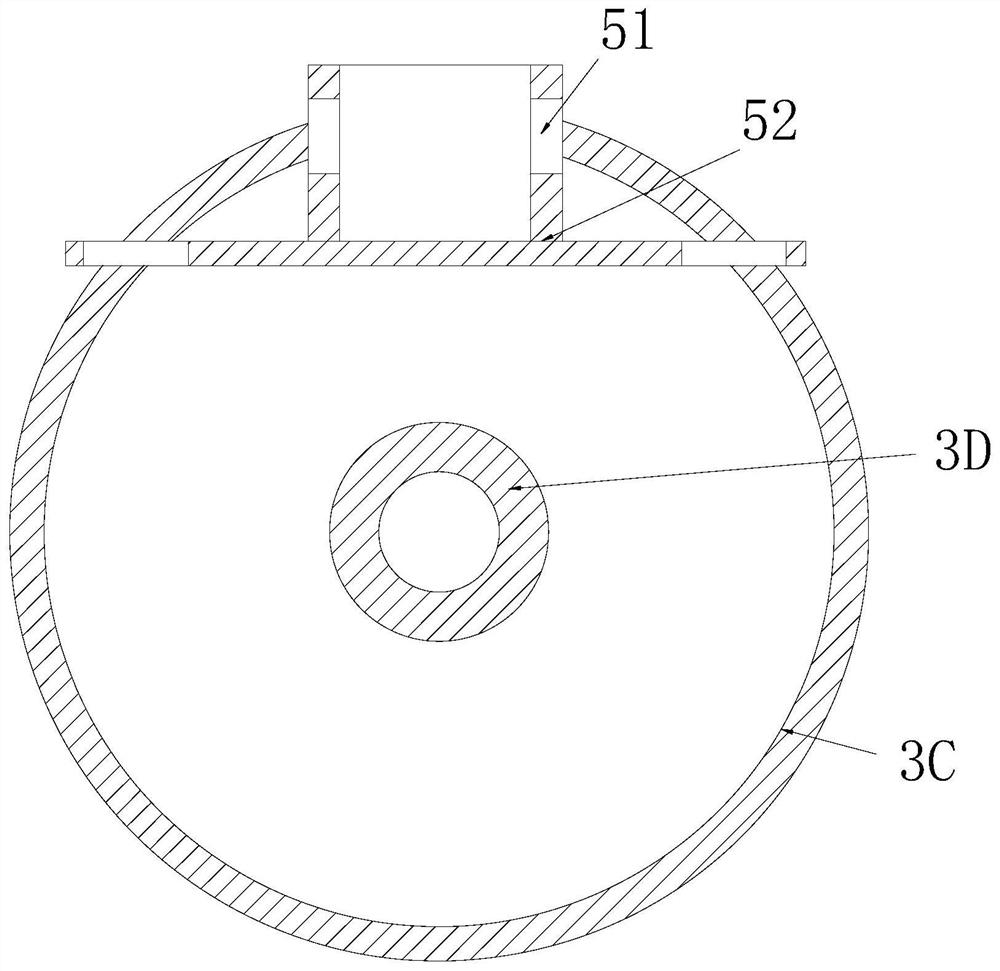

The invention relates to a device and method for extracting active principles from natural sources, using a counter-flow extractor assisted by a sound transduction system, which allows a cavitation sound field to be applied in the zone containing the material formed by the raw material of the natural product and a solvent extraction medium. According to the invention, the device (11) comprises: an inclined casing (12) containing a helical screw conveyor (13) having a plurality of blades (17), said casing including a lower end (15) and an upper end (16); a hopper (21) for introducing the material, which is disposed on top of the lower end (15) such that it is inclined at an angle # in relation to the surface of the casing (12), said feed hopper (21) including a second helical screw conveyor (22); an outlet hopper (31) for releasing the treated material, which hopper is located at the upper end (16) of the casing (12); a first load line (23) for loading the solvent extraction medium, which load line is located at the upper end (16); a discharge line (26) for discharging the liquid extract, which discharge line is located at the lower end (15) and is provided with a screen (27) that filters the liquid extract; and a sound transduction system (29) for producing ultrasound, which is located at the lower end (15) on a surface portion (28). The method comprises the following steps: (a) preparing the raw material; (b) supplying the product and the solvent to the device, in counter-flow mode; (c) applying a sound field to the product together with the solvent; (d) extracting the product with the extraction liquid, in counter-flow mode; and (e) collecting the liquid extract and the depleted material.

Owner:NATURAL RESPONSE SA

Extracting agent for extracting germanium and gallium and extraction method using same

ActiveCN102433435AEasy extractionPhase separation effect is goodProcess efficiency improvementChemistryMagnesium

The invention provides an extracting agent for extracting germanium and gallium and an extraction method using the same, relates to a hydrometallurgy extracting agent and in particular relates to an organic extracting agent for extracting germanium and gallium and an extraction method using the same. The extracting agent is characterized in that the extracting agent is O,O-dihydrocarbyl phosphorus hydroxamic acid the molecular formula of which is (RO)2P(O)NHOH, wherein in the formula, R is C5-C18 straight chain or branched chain alkyl, or C4-C14 straight chain or branched chain alkyl-substituted phenyl. The extracting agent provided by the invention has excellent extraction property, strong selectivity, high extraction rate and good phase splitting property on scattered metals such as germanium, gallium and the like. In the invention, O,O-dihydrocarbyl phosphorus hydroxamic acid is used as the extracting agent, so that germanium in an acidic aqueous solution can be extracted and enriched, or gallium in the acidic aqueous solution can be extracted and enriched, thereby realizing the separation of scattered metal germanium or gallium and elements such as zinc, iron, arsenic, manganese, calcium, magnesium and the like; and germanium and gallium in the acidic aqueous solution can also be extracted and separated step by step, thereby realizing the separation and enrichment of germanium and gallium.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

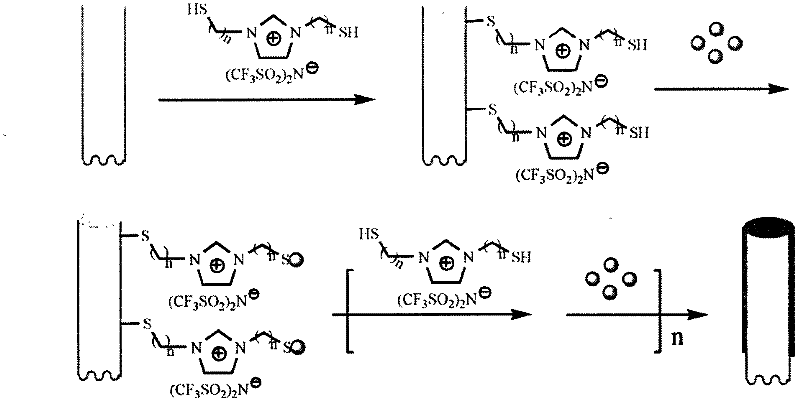

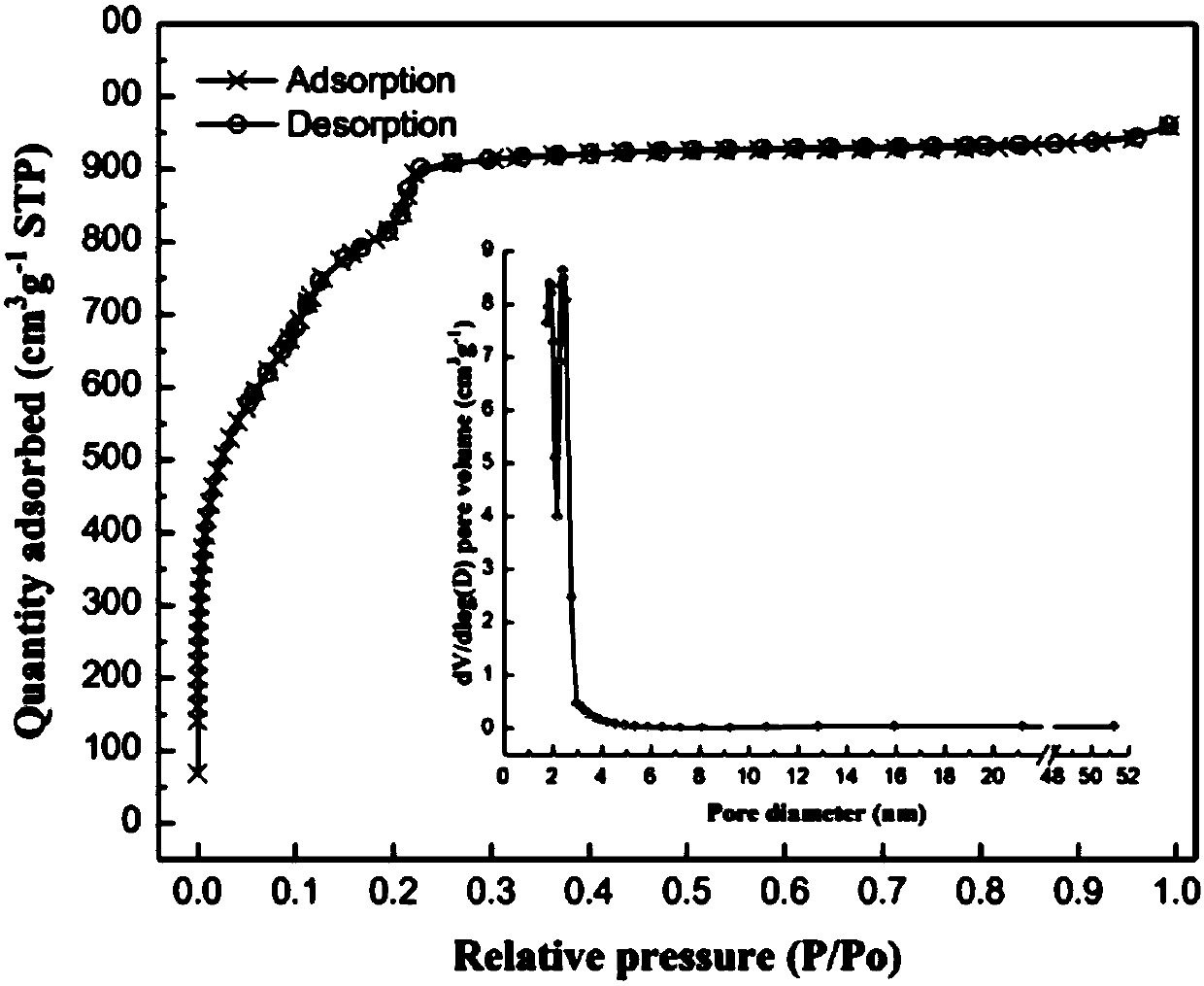

Preparation method for metal wire solid-phase micro-extraction fiber of noble metal nanometer material-ionic liquid composite functional coating

InactiveCN102489255AImprove fragile shortcomingsHigh mechanical strengthOther chemical processesFiberNanoparticle

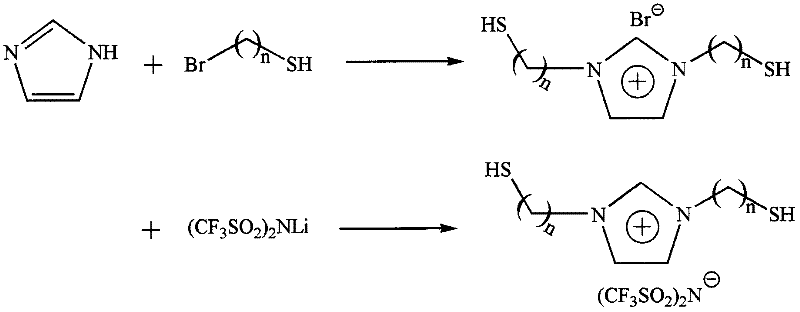

The invention discloses a method for preparing a solid-phase micro-extraction fiber of a noble metal nanometer material-ionic liquid composite functional coating on a metal wire carrier and particularly relates to a method in which ionic liquid is used as a bridge chain for the layer-by-layer self-assembly of noble metal nanoparticles on the metal wire carrier. The method is characterized by comprising the following steps of: selecting a metal wire as a carrier, adopting a layer-by-layer self-assembly method to modify ionic liquid with sulfhydryl groups to serve as the bridge chain, and assembling the noble metal nanoparticles on the metal wire layer by layer, thereby obtaining the novel solid-phase micro-extraction fiber of the noble metal nanometer material-ionic liquid composite functional coating. The solid-phase micro-extraction fiber prepared by the method has the characteristics of high mechanical strength, firm extracted coating, high adsorption capacity, long service life and the like, can be used for enriching and analyzing trace components in samples of foods, environments, medicines, biochemistry and the like and has very good application potential.

Owner:UNIV OF JINAN

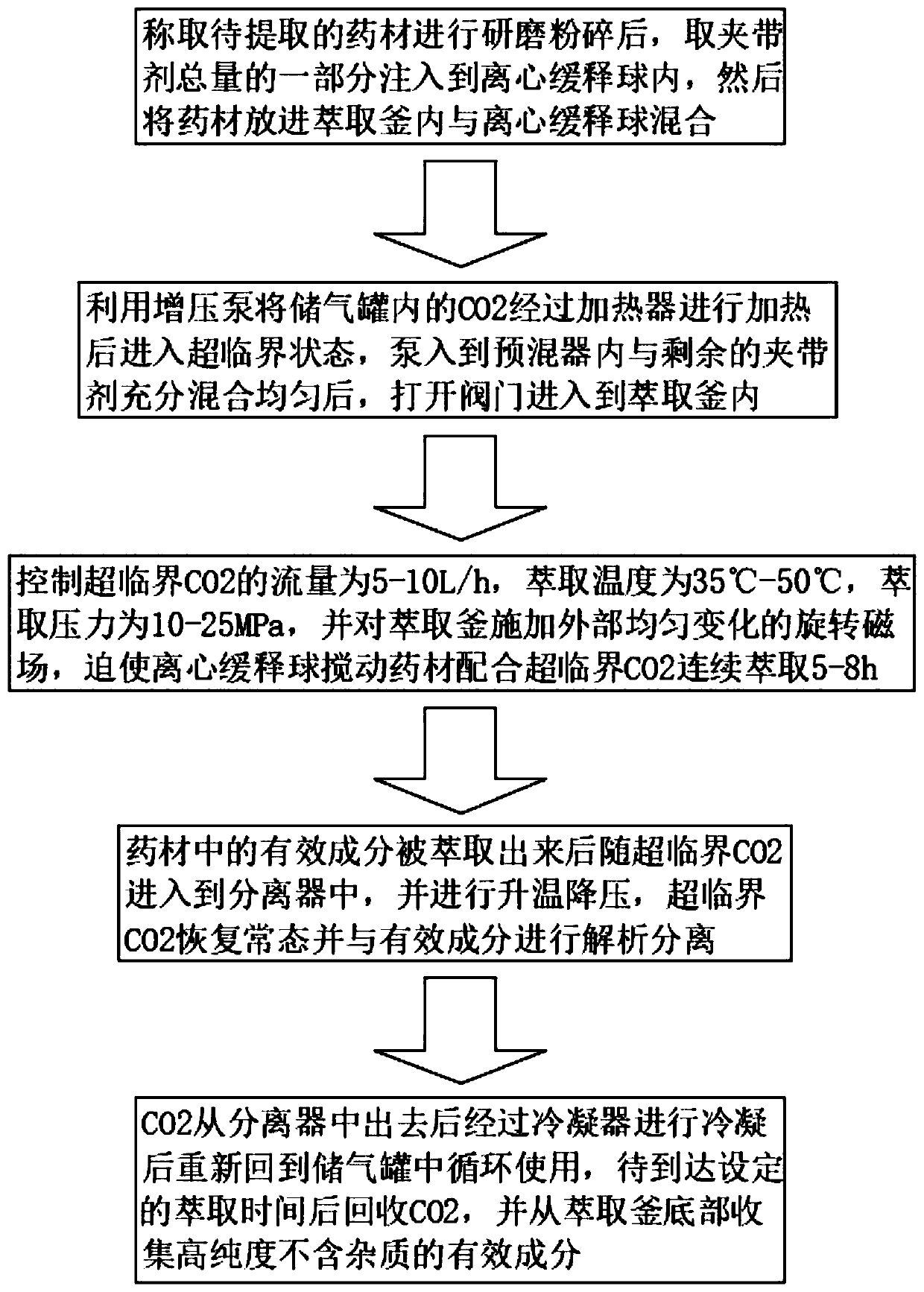

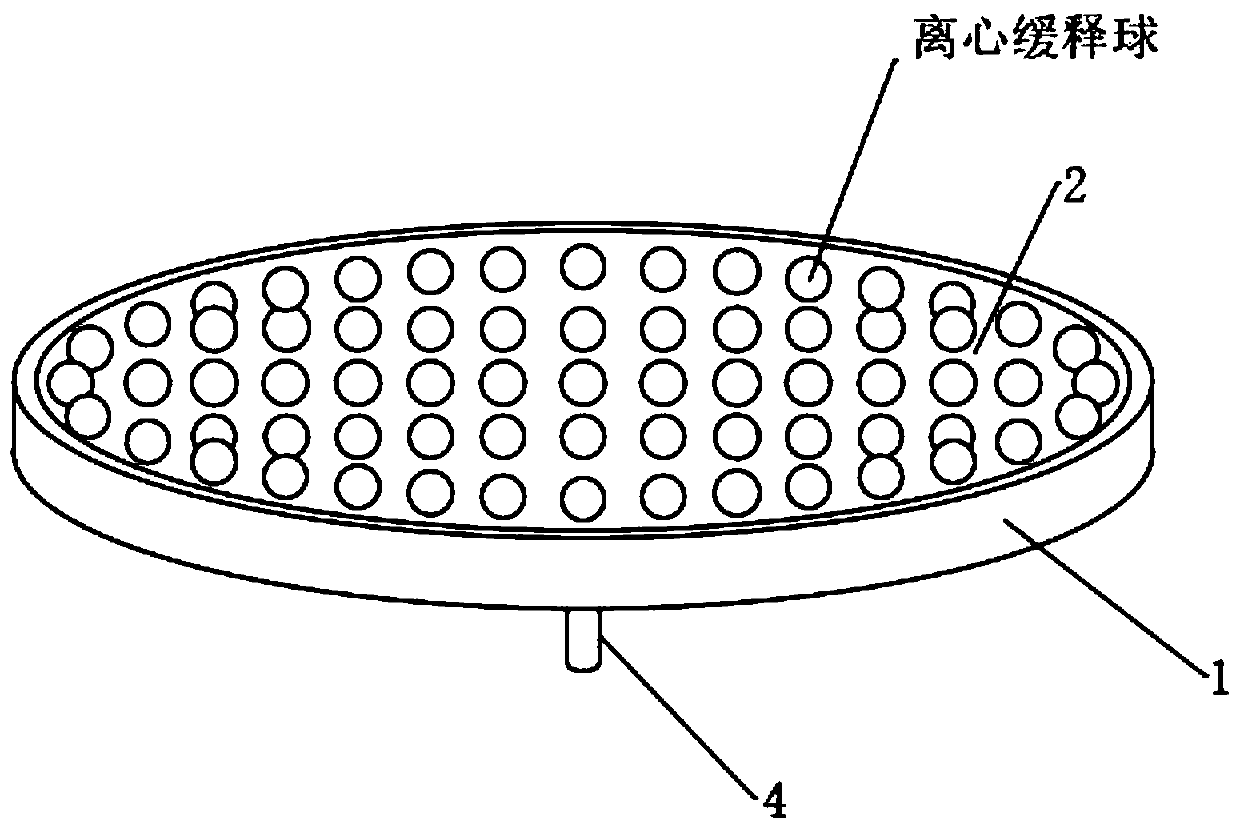

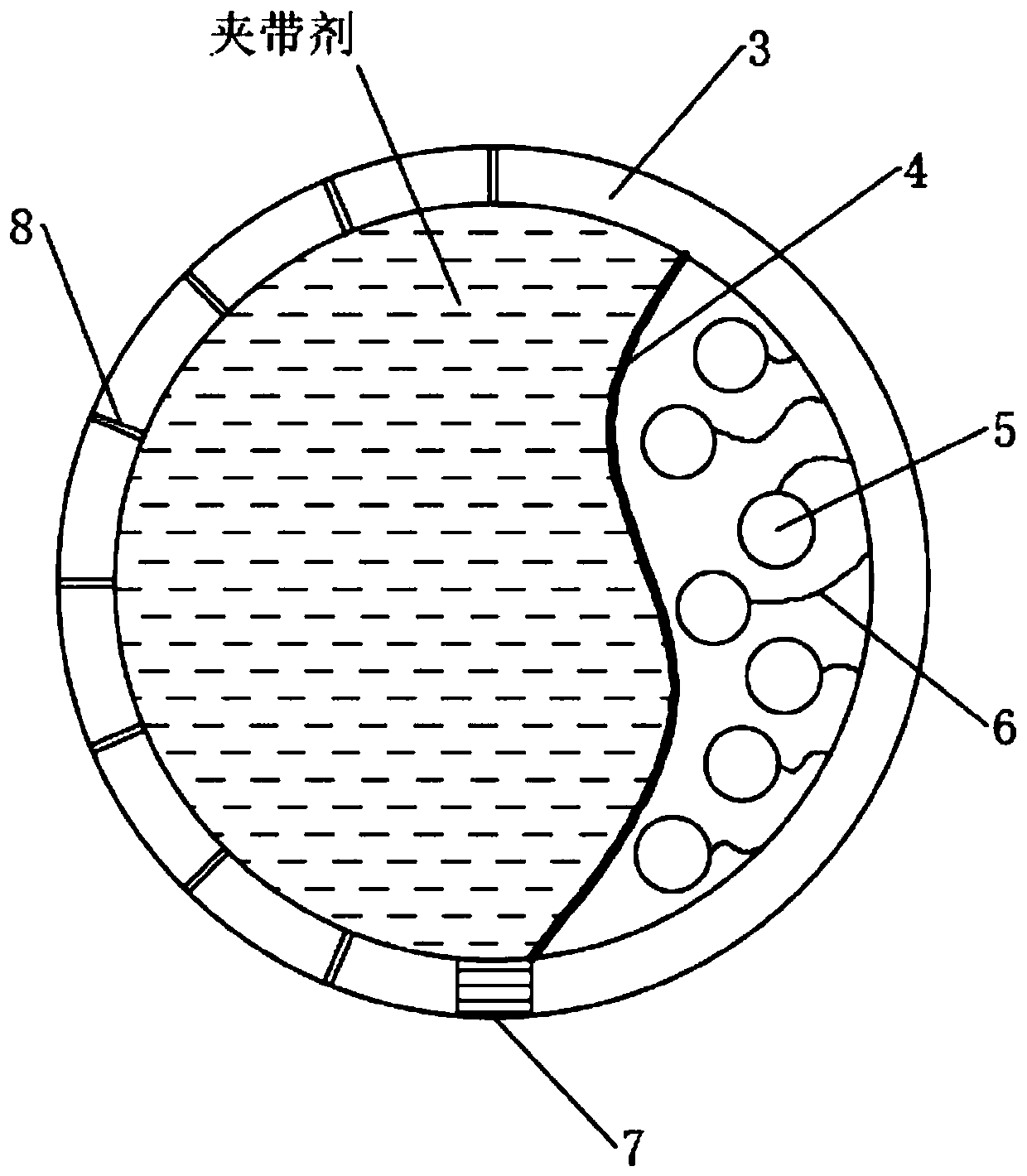

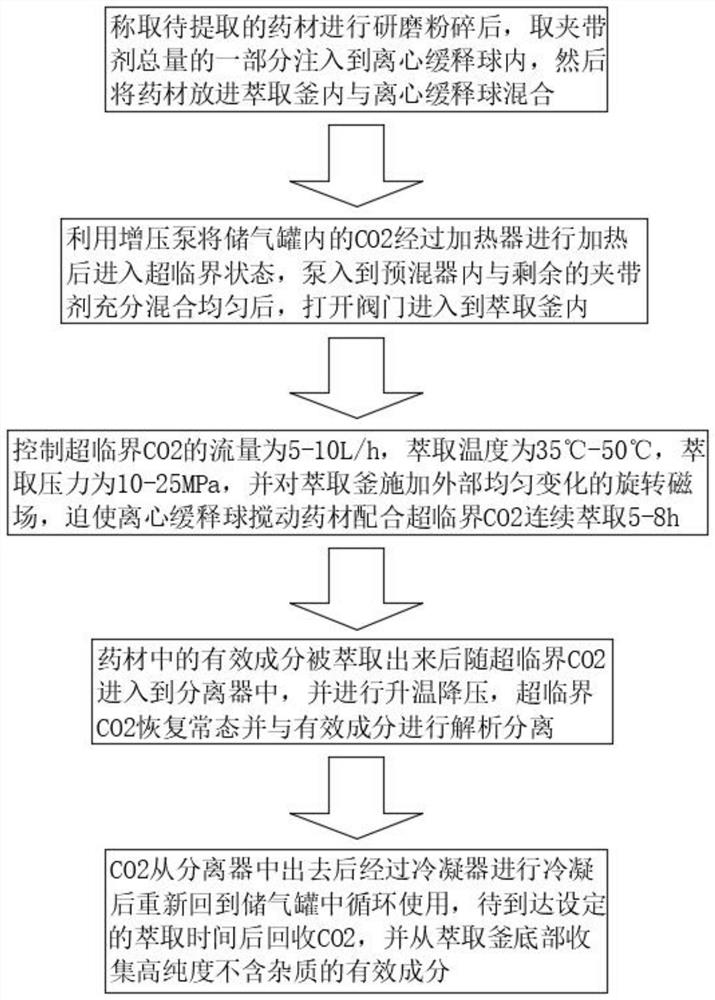

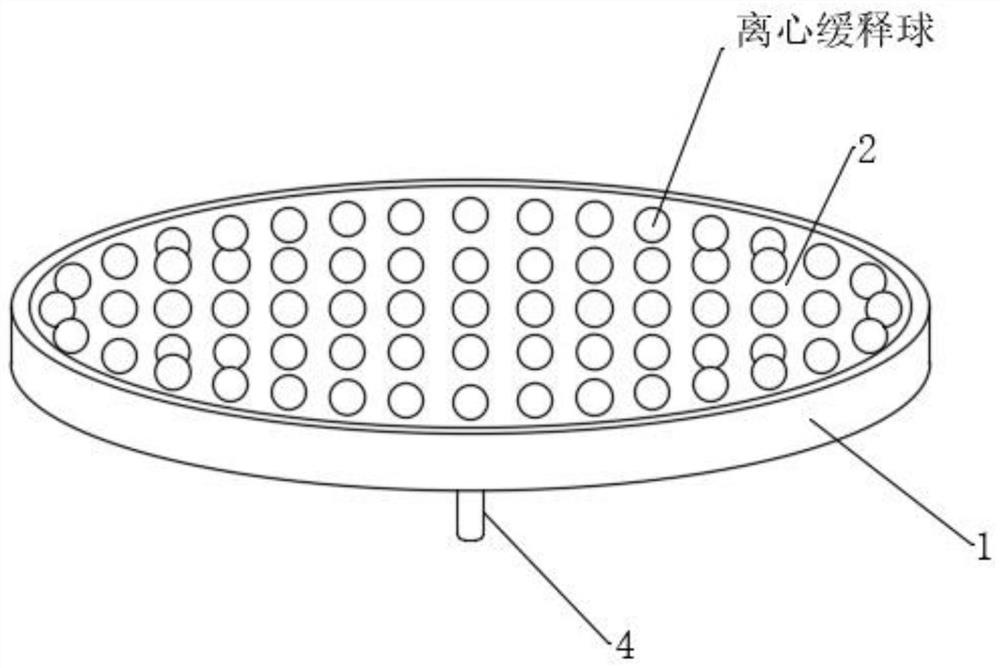

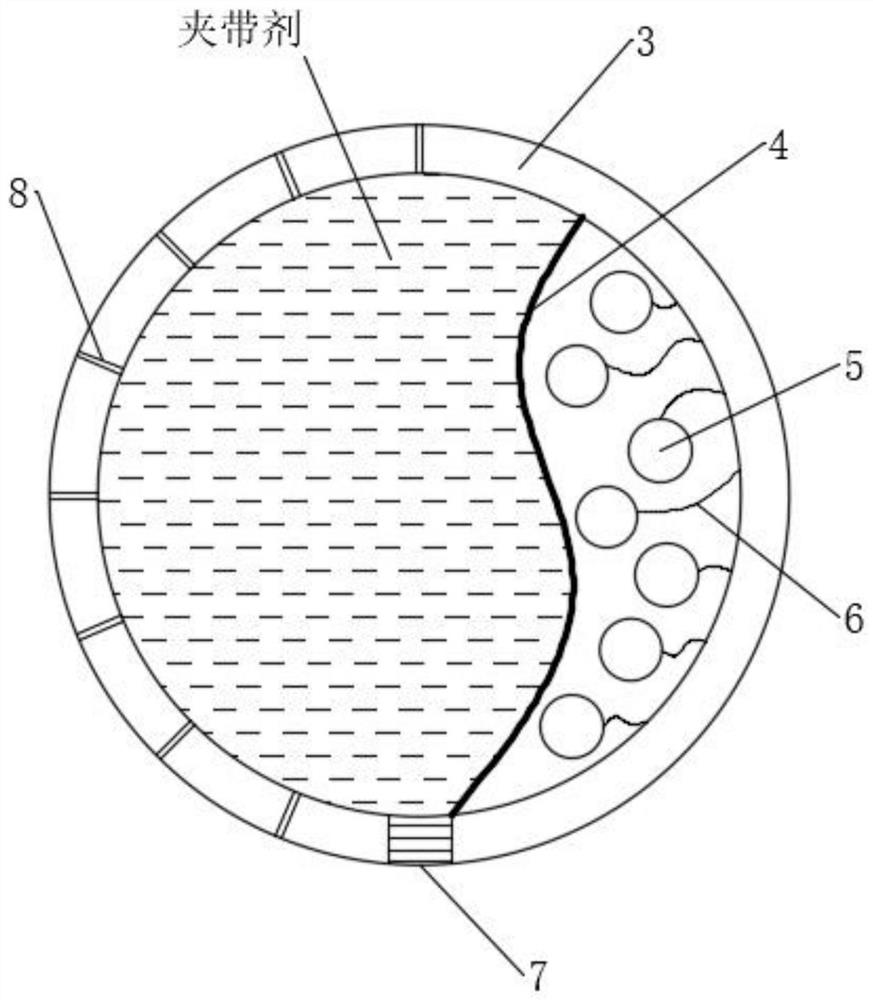

Novel entrainment type medicine preparation method based on supercritical CO2 extraction

ActiveCN111013188AImprove solubilityPromote formationPharmaceutical product form changeSolid solvent extractionMedicinal herbsActive agent

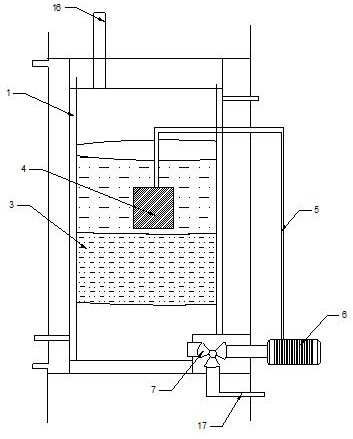

The invention discloses a novel entrainment type medicine preparation method based on supercritical CO2 extraction, belonging to the field of supercritical pharmaceutical technology. According to theinvention, a novel entrainer mixing mode is employed; most of an entrainer is injected into a centrifugal sustained-release ball, a small part of the entrainer is premixed with supercritical CO2; during extraction, a centrifugal rotation mode is adopted, the injected entrainer is slowly released into medicinal material powder and fully contacted with the medicinal material powder under the actionof extrusion, and the medicinal material powder is driven to continuously overturn, so a reaction is fully and comprehensively carried out under the atmosphere of supercritical CO2, the extraction properties of the entrainer are obviously improved, extraction efficiency is enhanced, effective components in medicinal materials are improved in solubility and sensitivity to temperature and pressure,and the separated components are separated from circulation gas through temperature and pressure so as to avoid high energy consumption caused by re-compression of gas; and the entrainer can even be used as a co-surfactant to facilitate the formation of a supercritical fluid micro-emulsion and has great advantages in the extraction of bioactive components in medicinal materials.

Owner:JIANGSU GAOKE PHARM EQUIP CO LTD

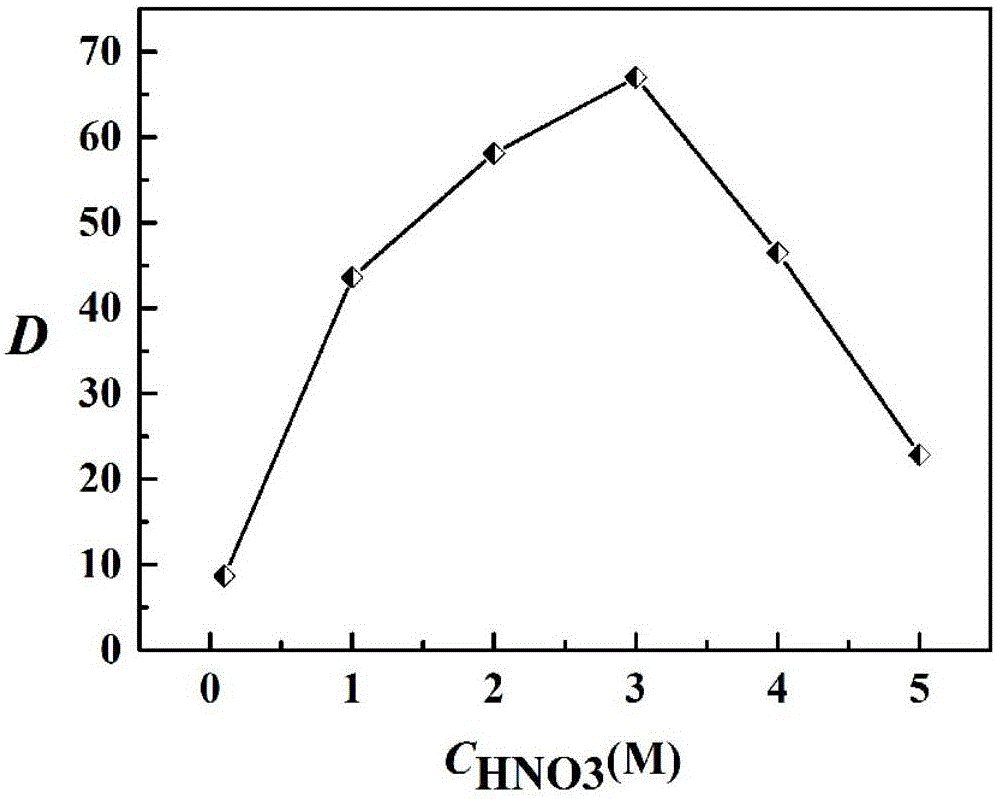

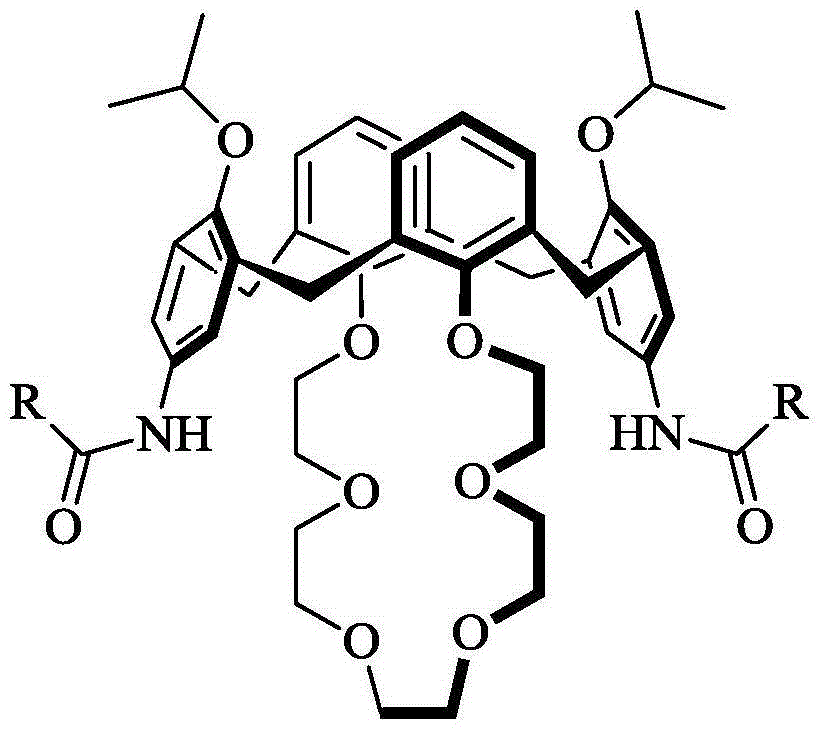

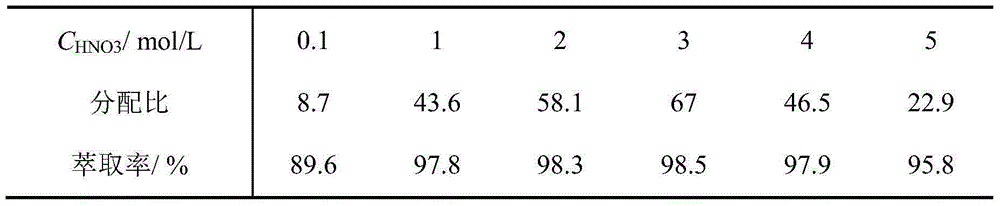

Bisamide-substituted novel calixcrown ether compound as well as synthesis method and application thereof

InactiveCN105130950AImprove hydrophobicityAvoid generatingOrganic chemistryProcess efficiency improvementSynthesis methodsEther

The invention relates to a bisamide-substituted novel calixcrown ether compound. The general chemical formula of the bisamide-substituted novel calixcrown ether compound is 11,23-di(acylamino)-25,27-di(2-propoxy)-calix[4]arene-crown-6; a synthesis method comprises the following steps: firstly, synthesizing an intermediate of 11,23-di(amino)-25,27-di(2-propoxy)-calix[4]arene-crown-6, and condensing the intermediate and acyl chloride so as to obtain the bisamide-substituted novel calixcrown ether compound. According to the synthesized 11,23-di(acylamino)-25,27-di(2-propoxy)-calix[4]arene-crown-6, the hydrophobicity of an extraction agent is increased by increasing the length of carbon chains of acylamino, the extraction distribution ratio of the calixcrown ether compound, in which acylamino is introduced, to caesium is increased by five times or above at least under the same extraction condition, the extraction performance is improved, the grade of an extraction device in the extraction process is reduced, the separation cost is reduced and the bisamide-substituted novel calixcrown ether compound has a high potential of being applied to removal of caesium ions in radioactive wastewater.

Owner:TSINGHUA UNIV

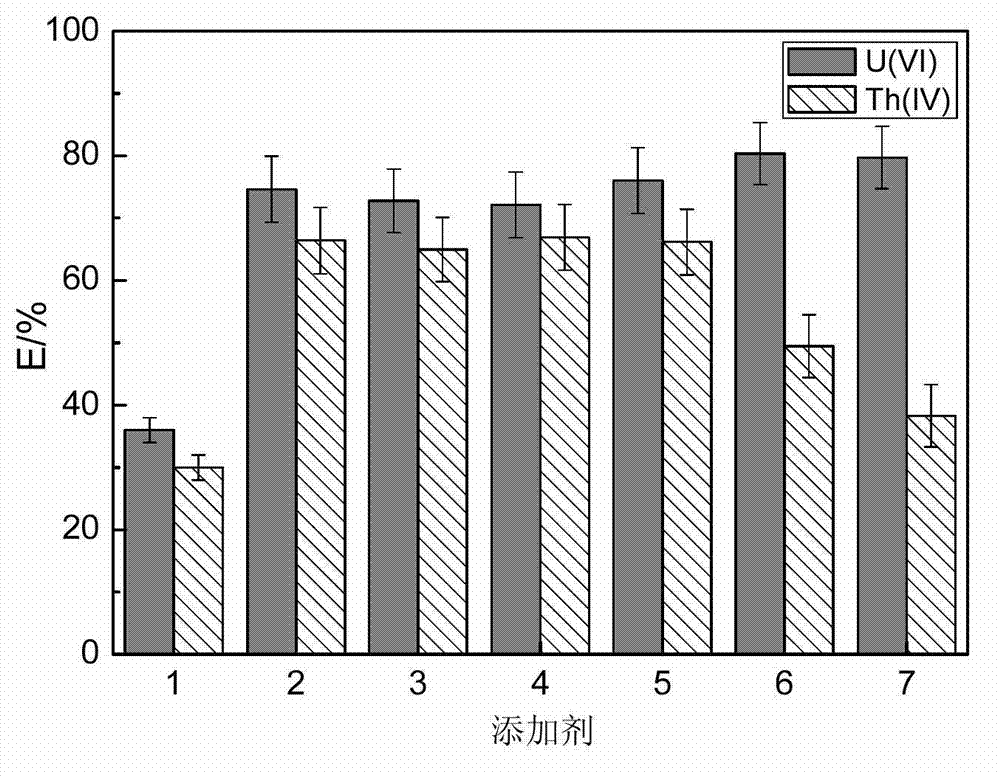

Method for enriching uranium and thorium from water phase by using cloud point extraction technology

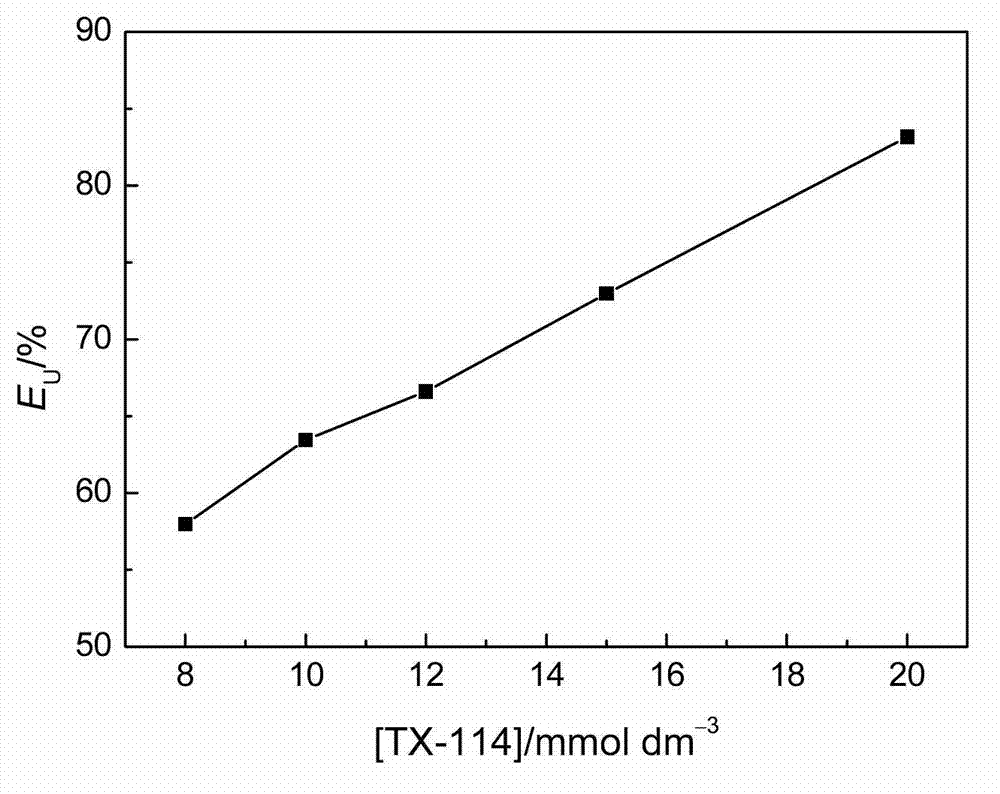

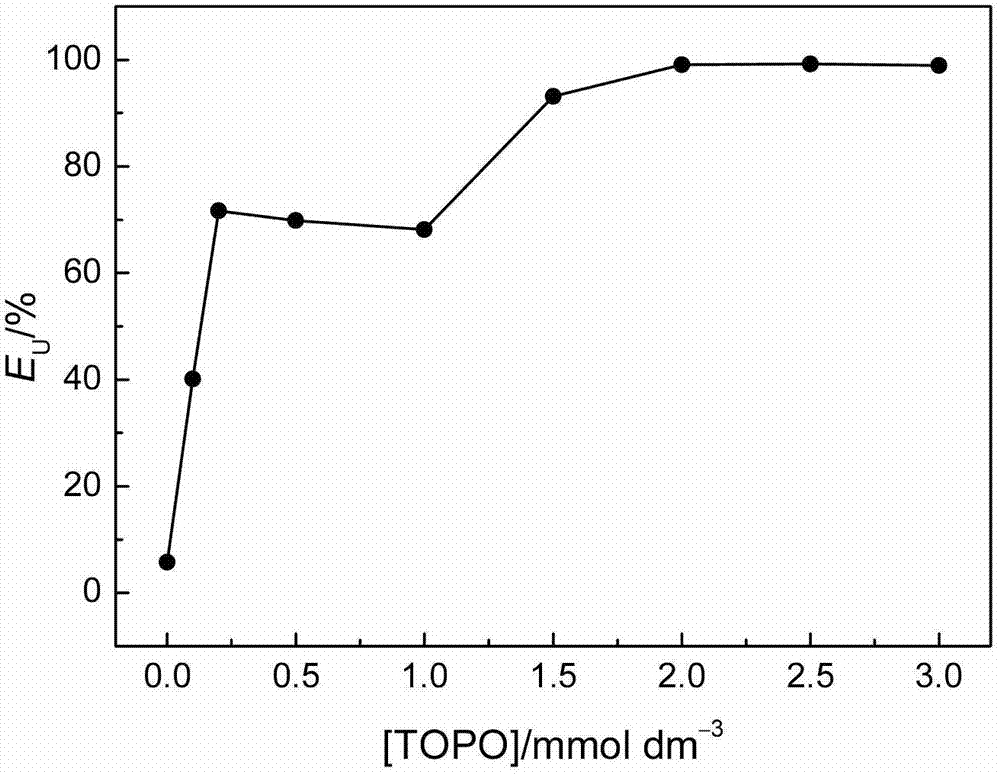

InactiveCN103045869AGood extraction performanceGood application prospectProcess efficiency improvementIonic strengthRadiochemistry

The invention discloses a method for enriching U (VI) or Th (IV) from a water phase by using cloud point extraction. The method adopts trialkyl phosphine oxide as extraction agent, TX-114 as surfactant and CnmimNTf2 hydrophobic ion liquid as additive to efficiently extract and separate out UO22+ or Th4+ from water solution under different conditions, wherein the water solution contains uranyl ions or thorium ions; and the ion strength of an extraction system is greater than or equal to 0.05 mol / L. The acidity range of the water phase adaptive to the method is large, so that the uranium and thorium ions can be remarkably extracted from the neutral condition to 2 mol / L HNO3. The cloud point extraction process is environment-friendly; and the method has wide prospects in the fields, such as uranyl enrichment and detection and the like.

Owner:PEKING UNIV

Treatment method of high-concentration phenolic wastewater generated in lignite upgrading process

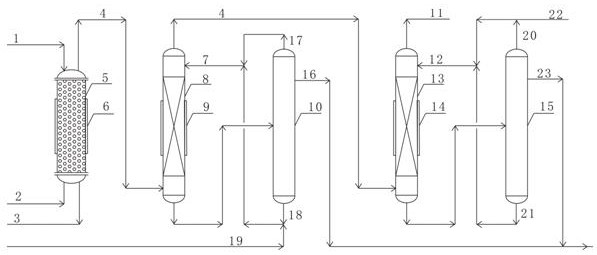

InactiveCN104909421AHigh extraction performanceImprove extractionWater/sewage treatment by extractionCounter currentChemistry

The invention discloses a treatment method of high-concentration phenolic wastewater generated in a lignite upgrading process. The method comprises the following steps: high-concentration phenolic wastewater subjected to deacidification and ammonia removal enters a plurality of extraction columns connected in series, each extraction column uses a fresh extractant to perform counter-current extraction on the phenolic wastewater, and cross-flow extraction is formed between every two extraction columns. The extractant can be methyl isobutyl ketone, mesityl oxide or tert amyl methyl ether. The number of the extraction columns can be 2-4. The amounts of the fresh extractants in the extraction columns can be different. After the wastewater treated by the method is subjected to solvent stripping, the optimal COD (chemical oxygen demand) can be down to 4000 mg / L below, and the total phenol content is lower than 220ppm, thereby completely satisfying the demands for conventional subsequent biochemical treatment.

Owner:SOUTH CHINA UNIV OF TECH

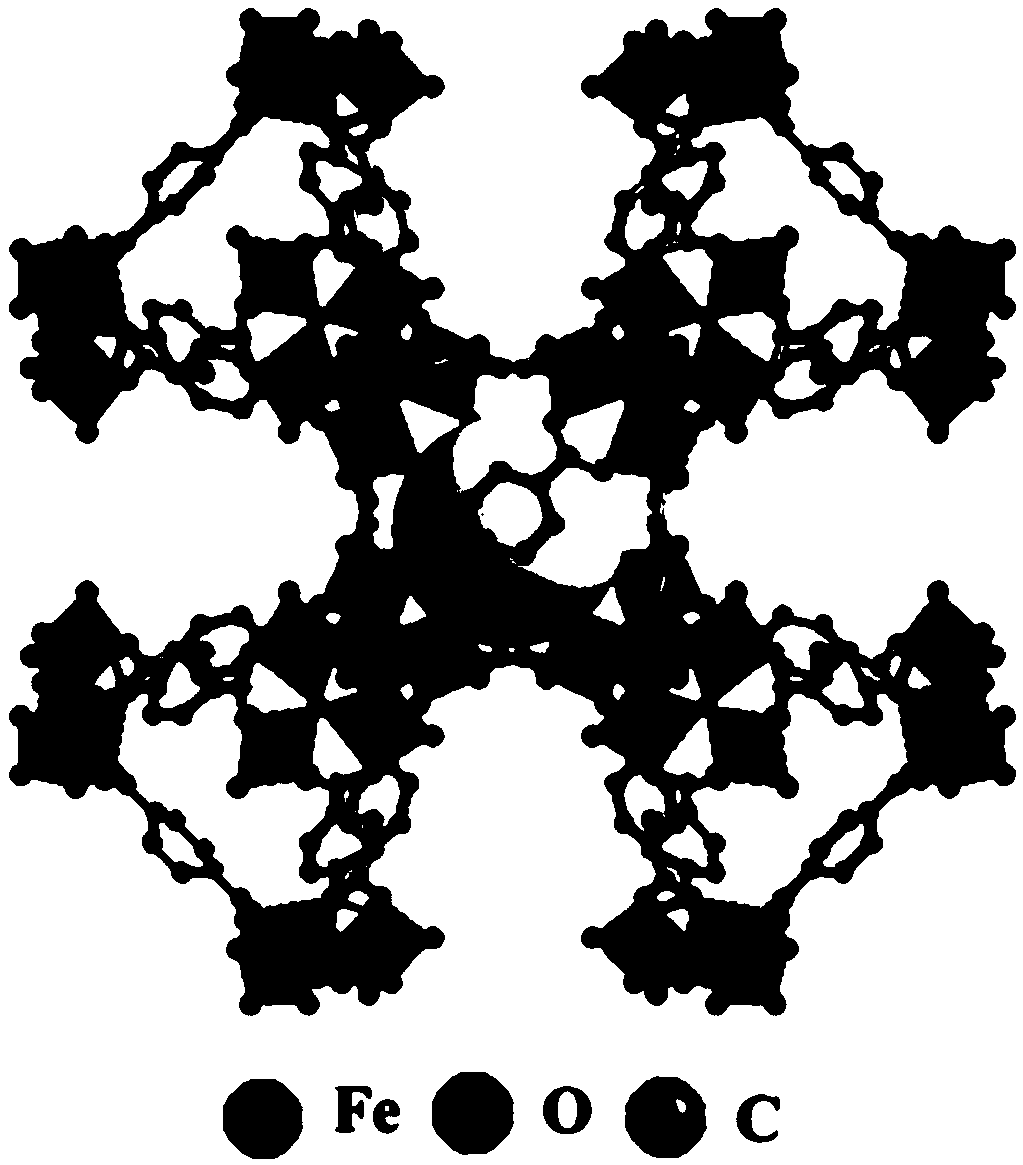

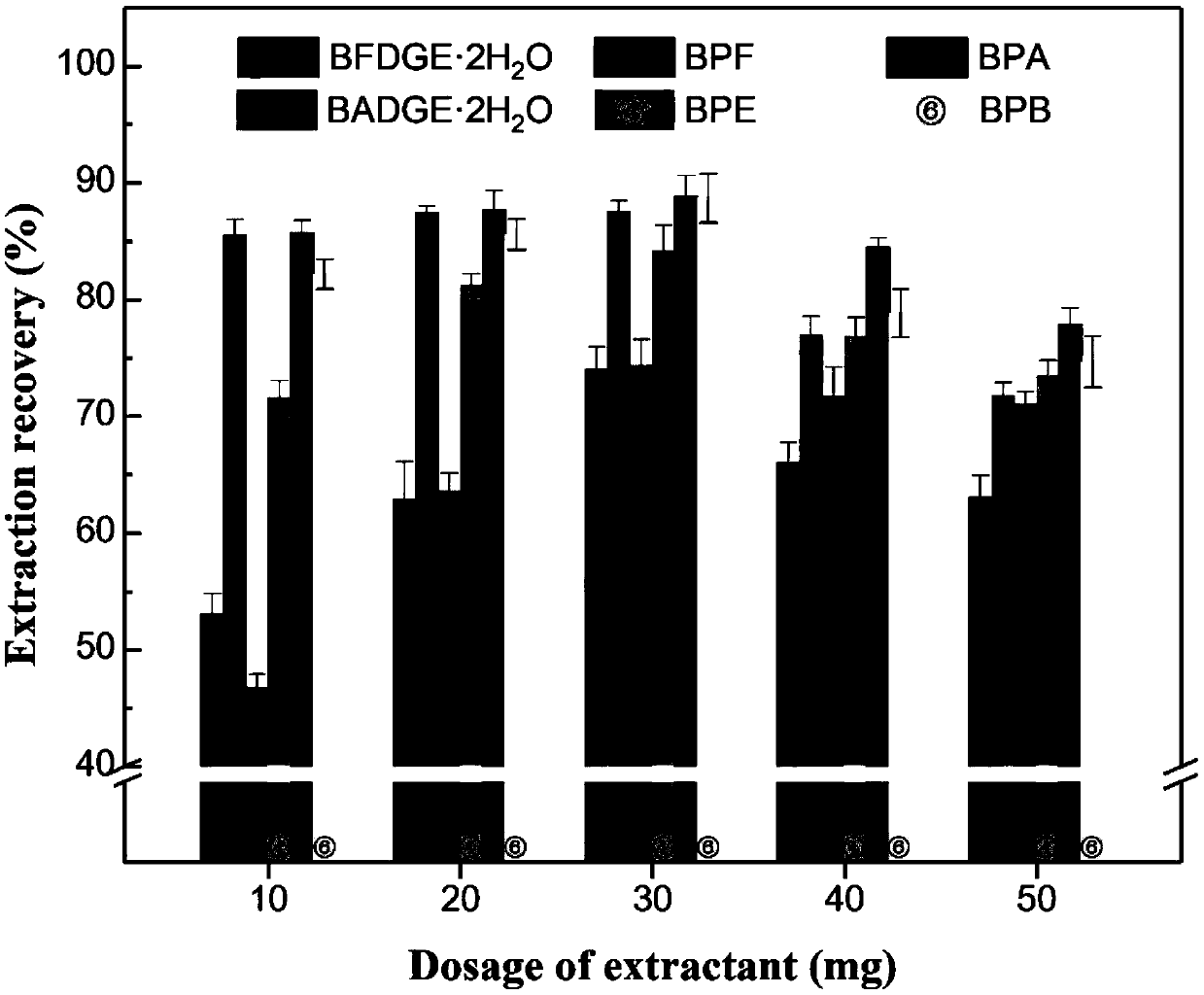

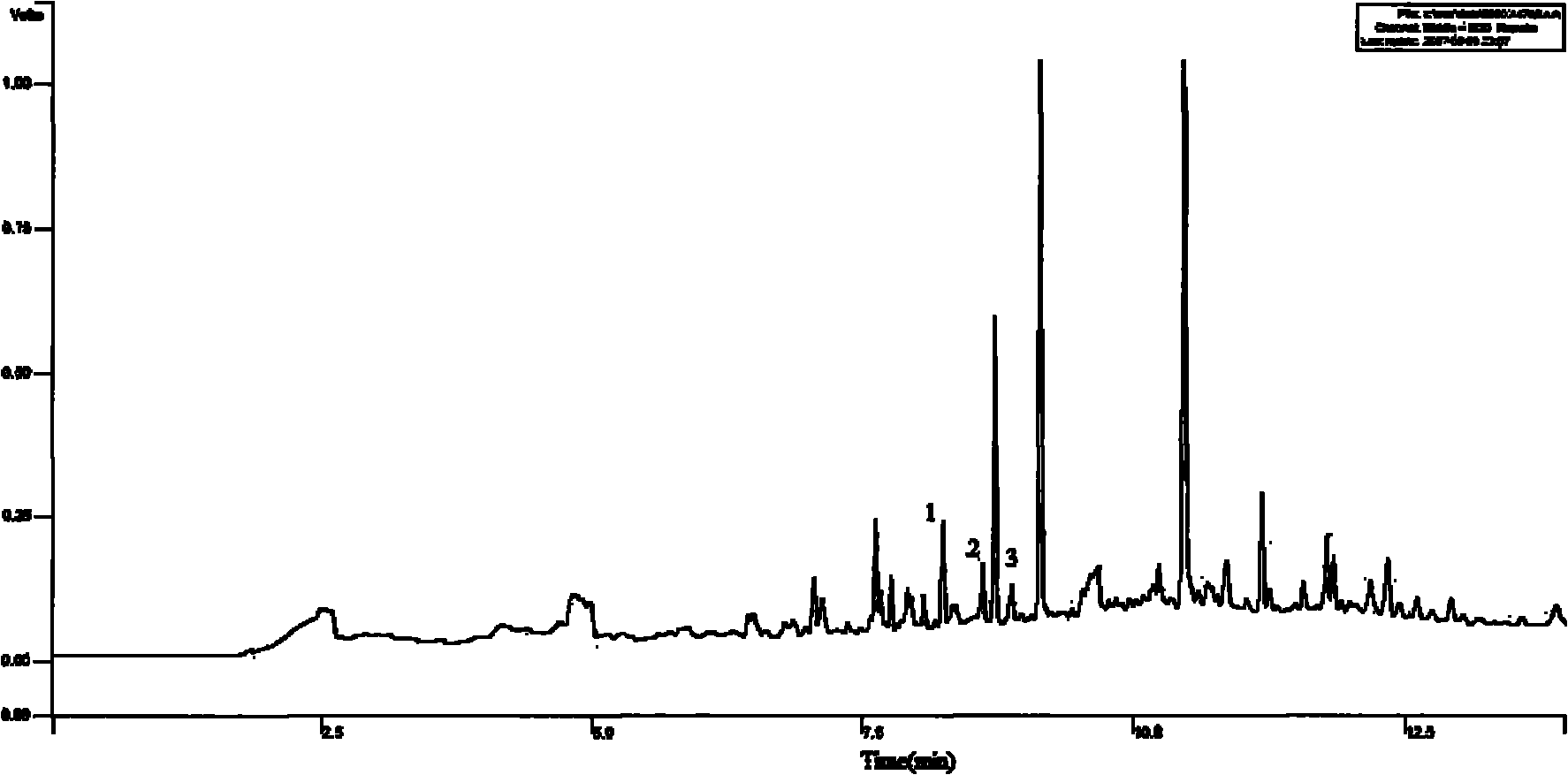

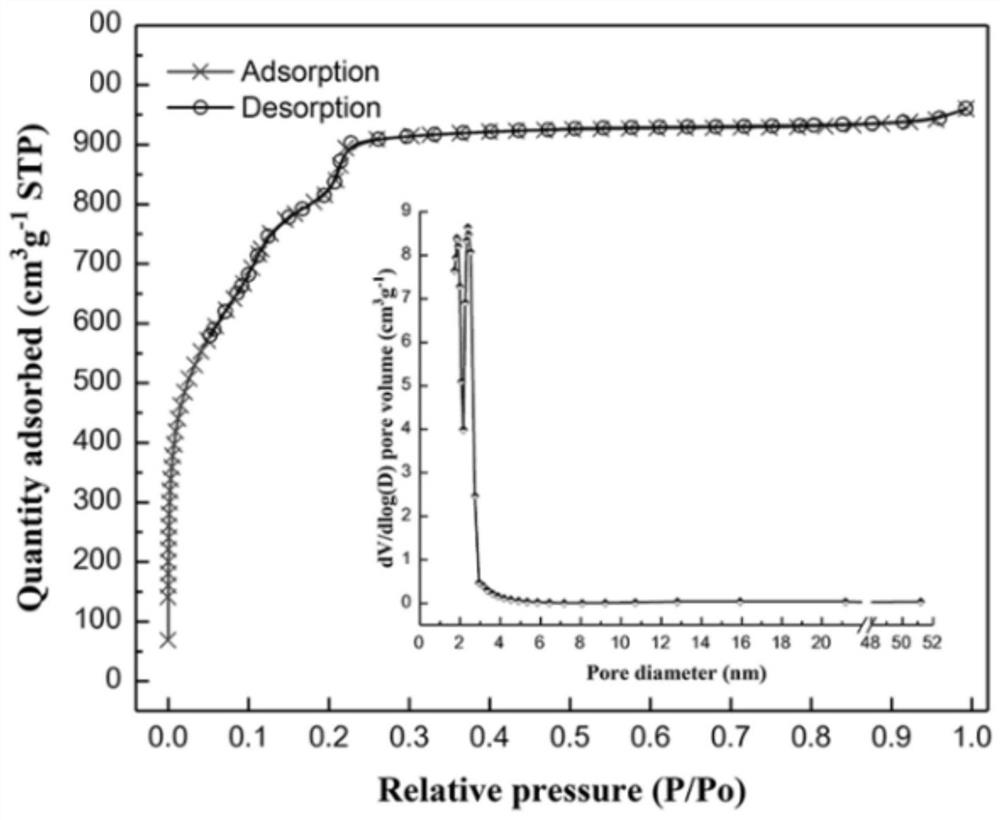

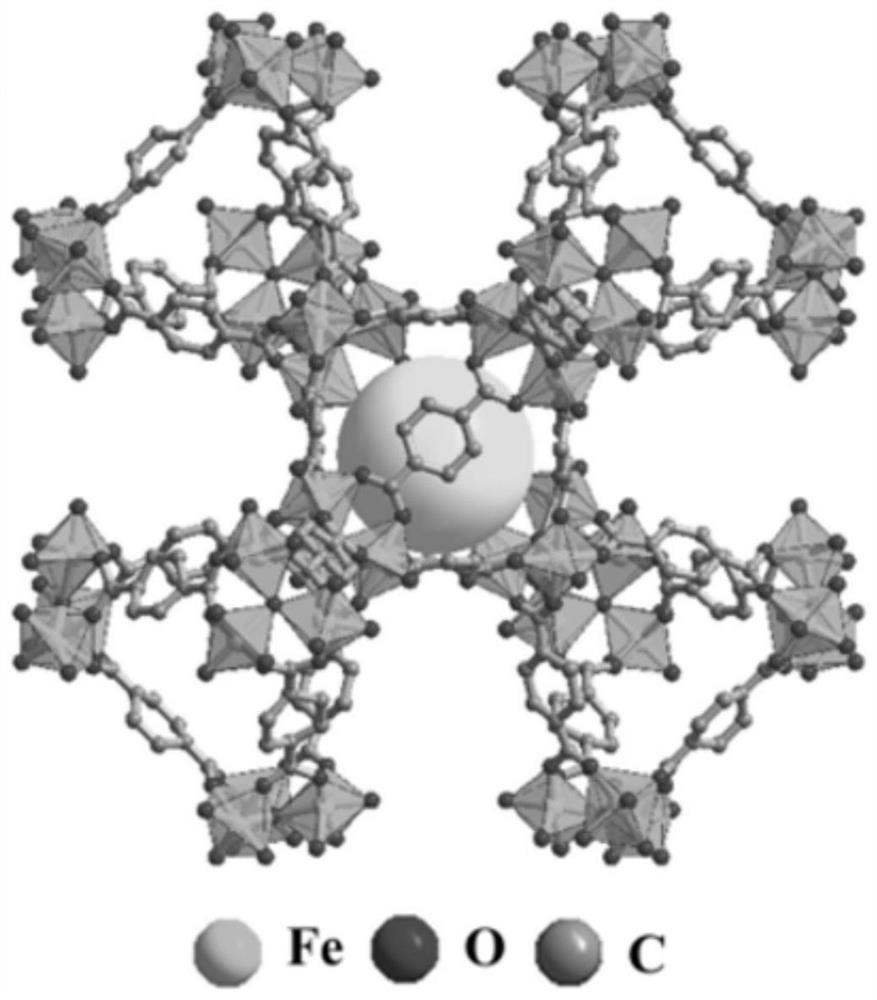

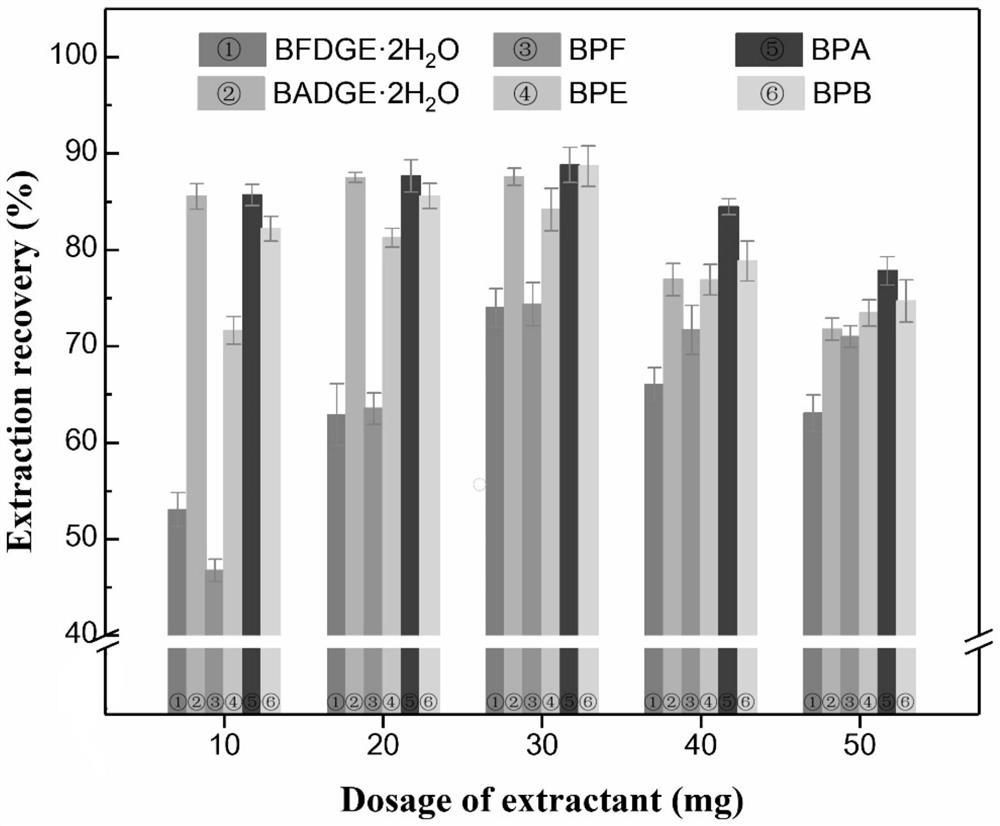

Method for detecting bisphenol compounds and derivatives of bisphenol compounds based on extraction technology of metal organic framework nanomaterials

The invention provides a method for detecting bisphenol compounds and derivatives of the bisphenol compounds based on extraction technology of metal organic framework nanomaterials. The nano materialis NH2-MIL-101 (Fe) material, and the bisphenol compounds and the derivatives thereof are in a log Kow range of 1.17-3.96, and are called BPS. The method comprises the following steps: S1, adsorbent NH2-MIL-101 (Fe) is added into a sample containing the BPS, the PH value of the sample is adjusted within the range of 2.0 to 7.0, and ultrasonic treatment is carried out for 1.5min to 5.0min so as toobtain the ultrasonic liquid; S2, centrifugal treatment is carried out on ultrasonic liquid obtained in the step S1 to obtain liquid A, and liquid B is obtained after supernate M of the liquid A is removed; S3, after the liquid B obtained in the step S2 is subject to vortex elution for 1.0-5.0min by using an eluent, liquid C is obtained, supernate N of the liquid C is collected, and the eluent isone of methanol, acetonitrile and acetone; and S4, after constant volume is carried out on the supernate N in the step S3, chromatographic analysis and quantification is made.

Owner:WENZHOU MEDICAL UNIV

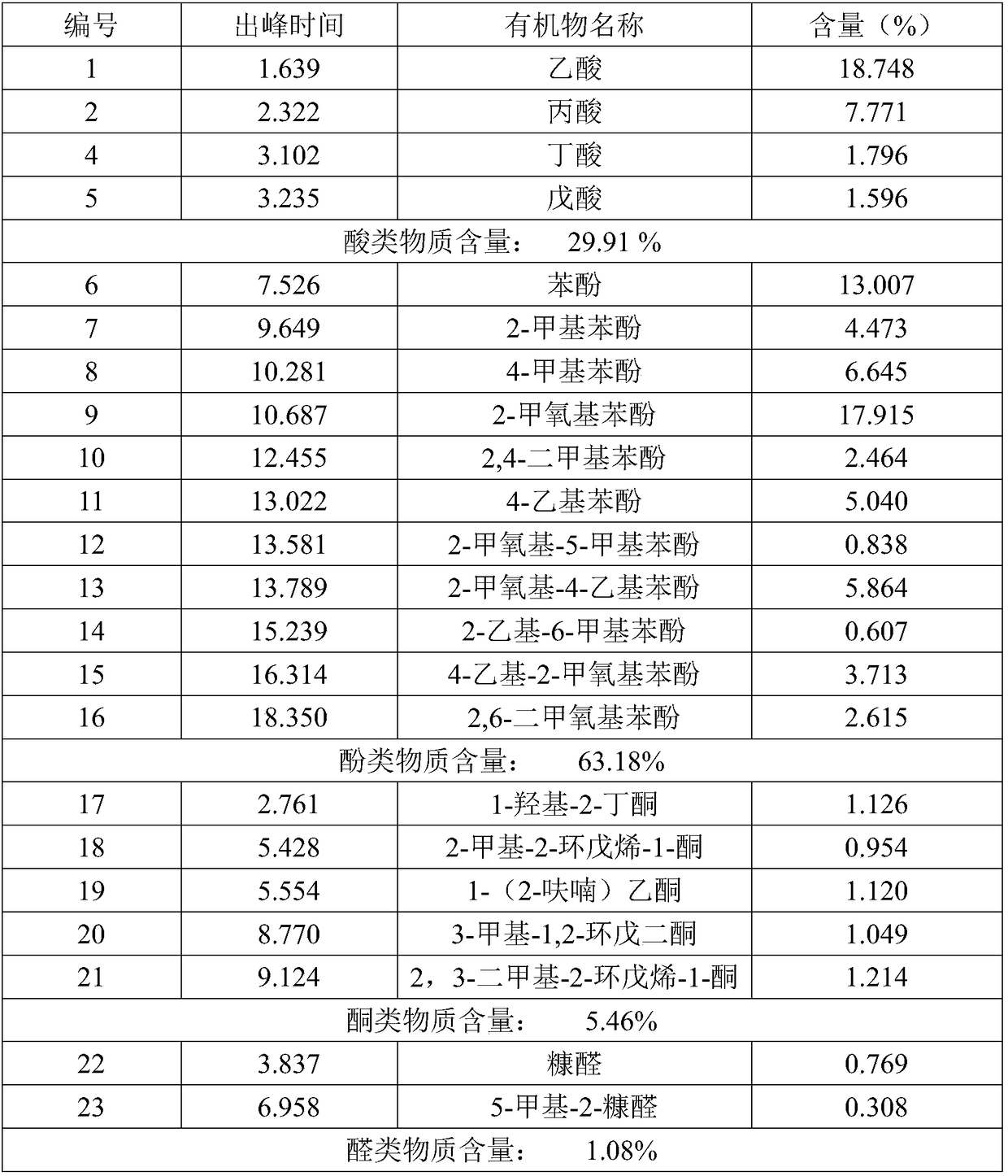

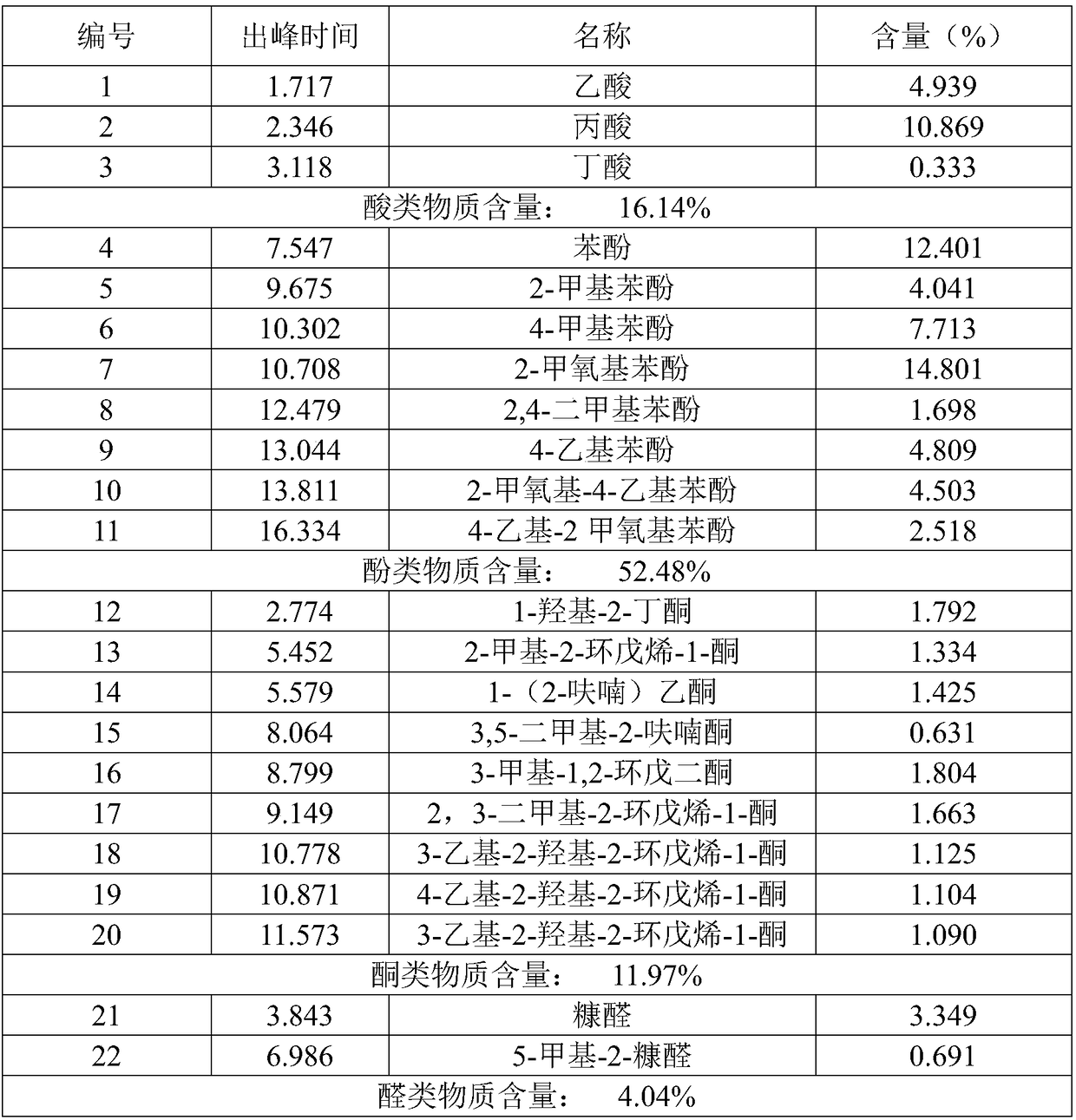

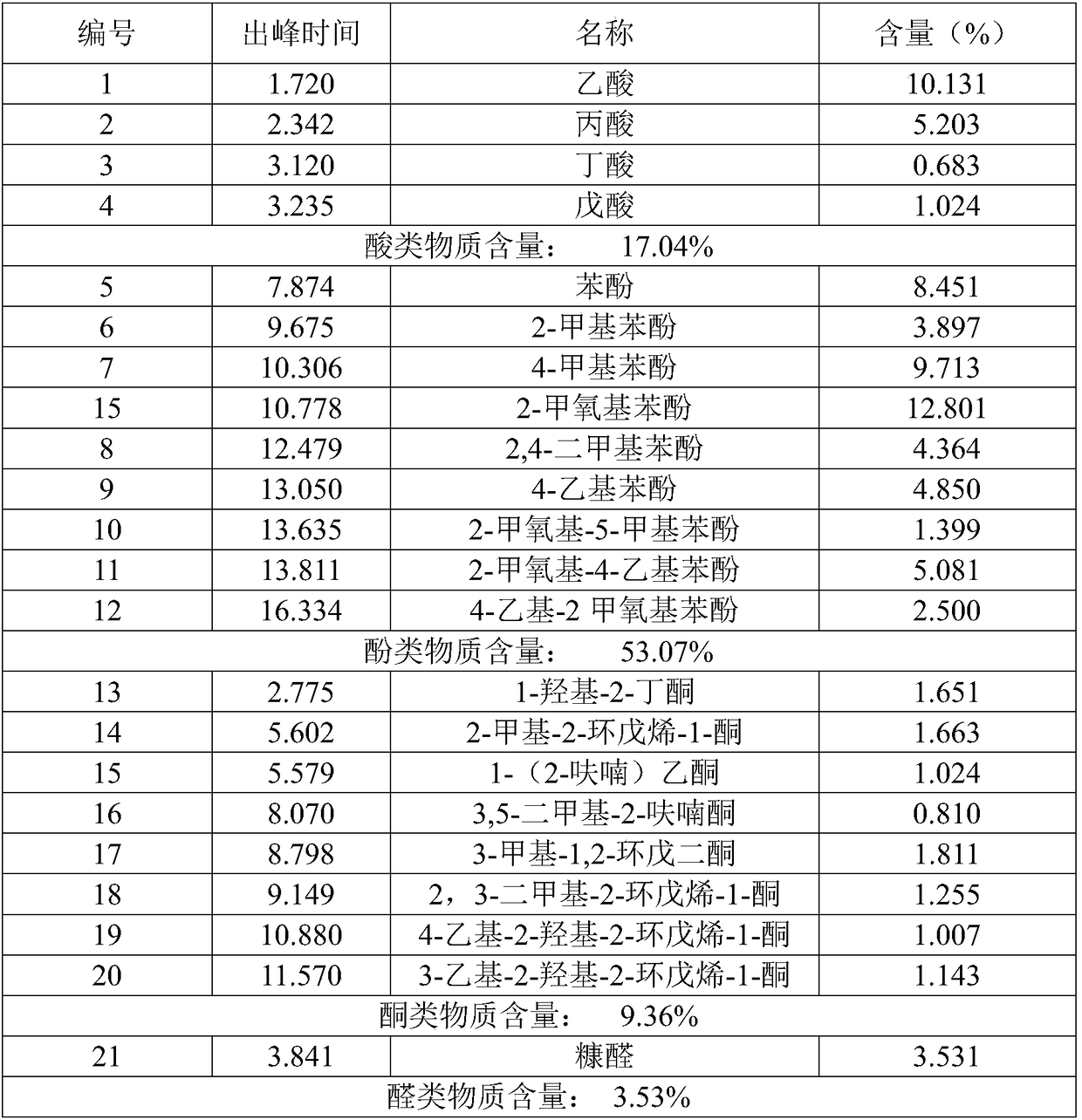

Method for enriching acid substances and phenolic substances in wood vinegar

InactiveCN108434782AEfficient enrichmentImprove directional refinementBiofuelsLiquid solutions solvent extractionRoom temperatureDiethyl ether

The invention discloses a method for enriching acid substances and phenolic substances in wood vinegar. Crude wood vinegar is extracted by using an extractant to obtain refined wood vinegar; the extractant is a mixed extractant formed by mixing diethyl ether and methanol; the diethyl ether and the methanol are mixed according to a volume ratio of 1-5 to 1; the contents of the acid substances and the phenolic substances in the refined wood vinegar can reach 26.91% and 63.18%; during extraction, the mixed extractant is used for multiple extractions, then extracts are mixed, and the mixed extractis volatilized by standing at a room temperature to obtain the refined wood vinegar. The mixed extractant of the diethyl ether and the methanol is selected for use, and through the adjustment of a mixing ratio of the two and full use of strong polarity and co-solubilization of the methanol and the diethyl ether, the acid substances and the phenolic substances in the wood vinegar are effectively enriched; the contents of the acid substances and the phenolic substances can reach 26.91% and 63.18%, so that the directional refining effect of the wood vinegar is greatly improved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

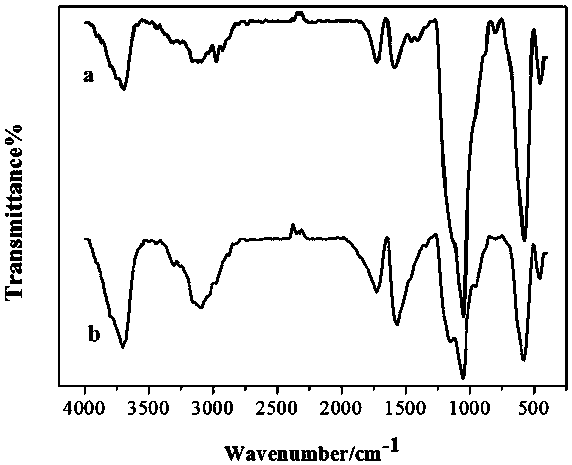

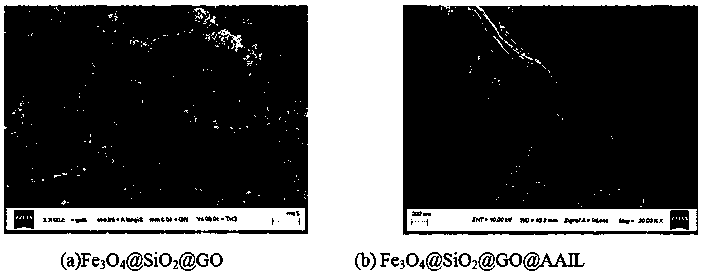

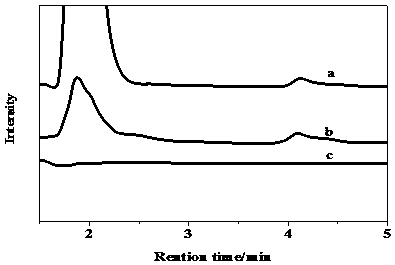

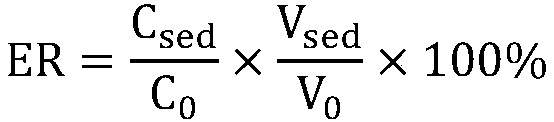

Tryptophan ionic liquid loaded magnetic graphene oxide nano composite material and tebuconazole extraction detection method thereof

ActiveCN110187039AStrong adsorption capacityHigh extraction performanceComponent separationCvd grapheneIon

The invention relates to a tryptophan ionic liquid loaded magnetic graphene oxide nano composite material and a tebuconazole extraction detection method thereof in the field of inorganic chemistry. Tryptophan ionic liquid is loaded on the surface of Fe3O4@SiO2@GO nano particles, and then the material is applied to tebuconazole sample solution, and separation and analysis of bactericide-tebuconazole in an environmental sample can be realized by combination with a high performance liquid chromatography-ultraviolet detector. Results show that: the tebuconazole can be rapidly and qualitatively adsorbed by Fe3O4@SiO2@GO@[C4mim]Try nano particles, the extraction rate of the tebuconazole in a detected sample reaches over 95.0%, the detection limit of the tebuconazole extraction detection method is 0.014[mu]g / mL, the linear range is 0.016-40.00[mu]g / mL, and a concentration factor is 20.0. The tebuconazole extraction detection method successfully performs measurement on water, rice, corn and soil samples.

Owner:YANGZHOU UNIV

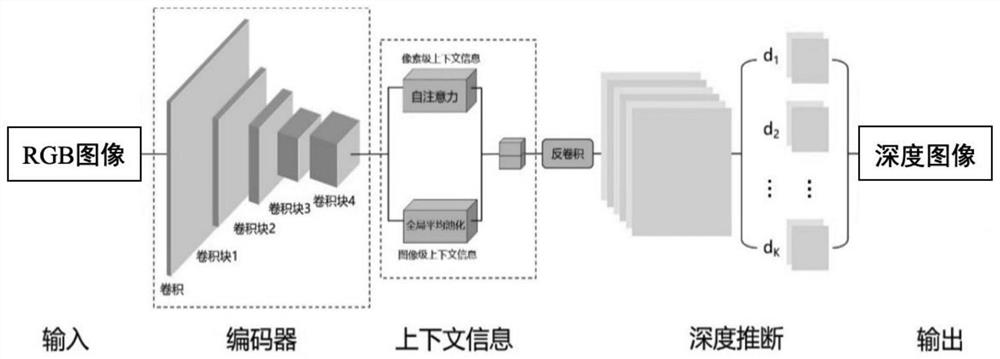

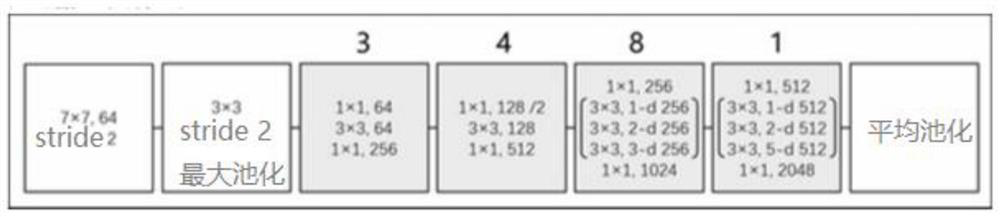

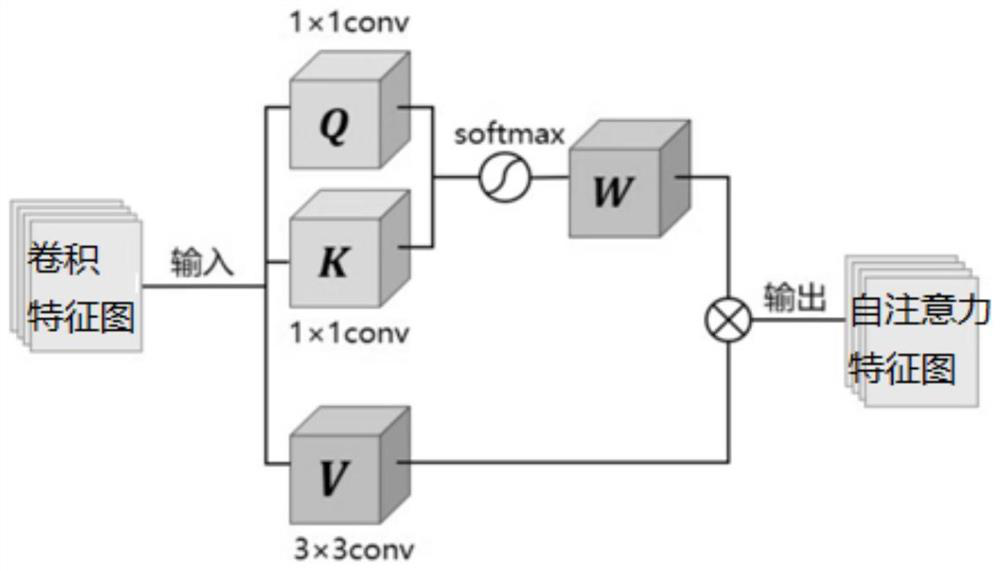

Monocular image estimation method based on multi-classification regression model and self-attention mechanism

PendingCN113222033AReduce overfittingReduce mistakesCharacter and pattern recognitionNeural architecturesComputer visionDeep neural networks

The invention discloses a monocular image estimation method based on a multi-classification regression model and a self-attention mechanism, and the method comprises the steps: firstly inputting an image, carrying out the replacement of convolution in a convolution unit block through an image encoder, and carrying out the replacement through hole convolution; acquiring pixel-level context information according to a self-attention model after encoding an image encoder, firstly processing an input feature map through a single-layer neural network and a ReLU function, and then acquiring global context information of an image by performing global average pooling on the input feature map; entering scene depth soft inference, classifying input image pixels into depth classes, and performing ordered regression on depth values; and obtaining accurate and smooth depth values by using data provided by a probability map, and obtaining depth inference values of pixels at positions. According to the invention, the depth design of the monocular image scene is carried out by using the ordered classification logistic regression model, the self-attention mechanism and the deep neural network, and the grid effect caused by repeatedly using the same cavity convolution kernel is reduced.

Owner:北京数研科技发展有限公司

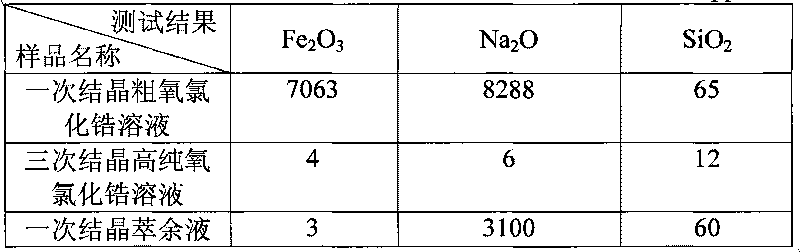

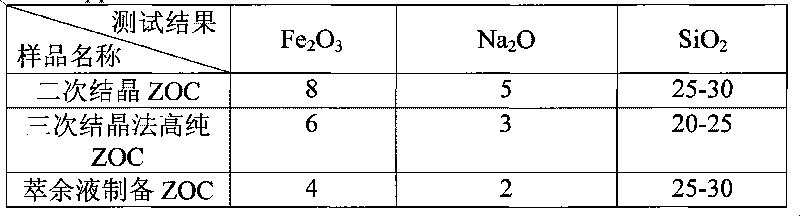

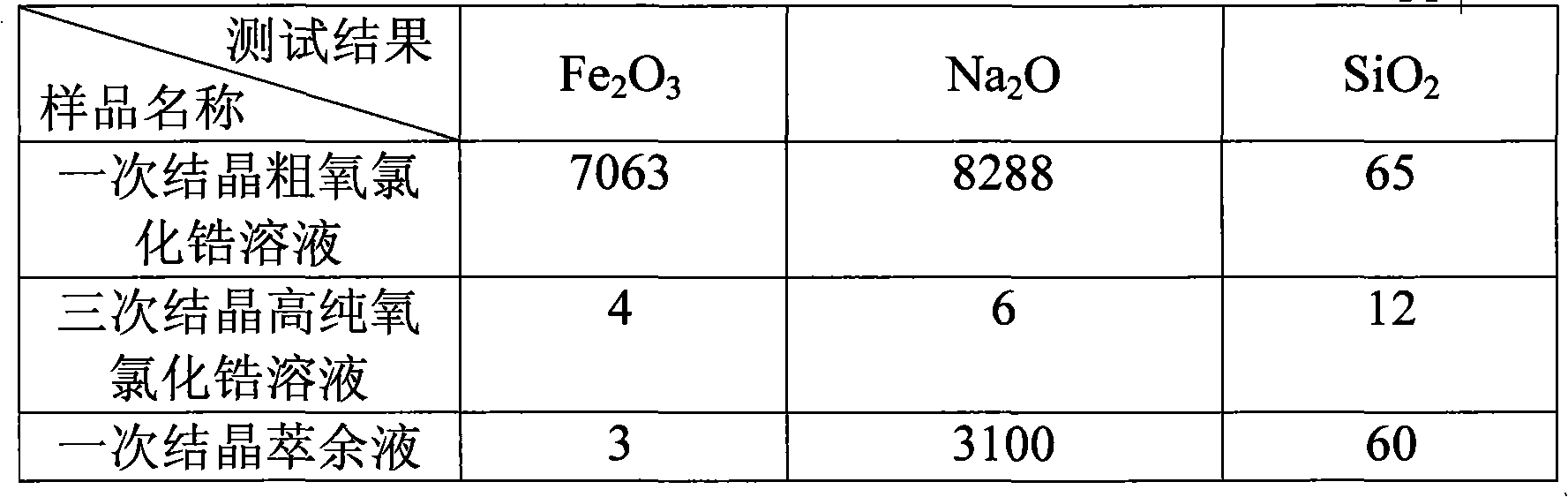

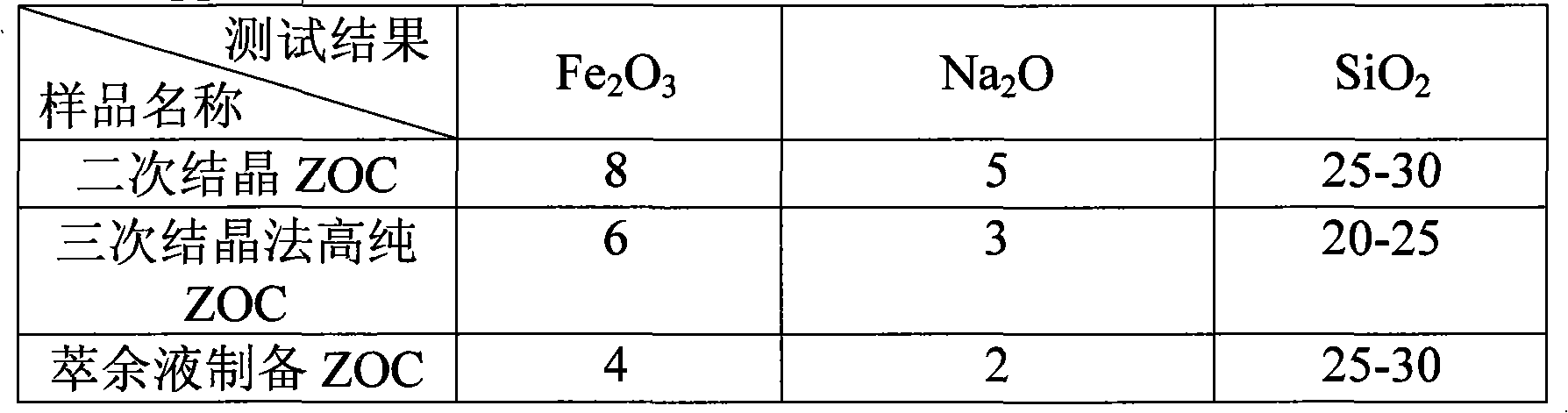

Process for preparing high-purity zirconium oxychloride

The invention discloses a process for preparing high-purity zirconium oxychloride, which comprises the following steps: pumping crude zirconium oxychloride solution into a high-level barrel for later use, and pumping purified water into an organic regenerative section of an extraction tank; evenly stirring N, N-di (1-methyl heptyl) acetamide and sulfonated kerosene in a volume ratio of 1:1-9, and quantitatively pumping the mixture into the extraction tank and pumping the excess into the circular organic high-level barrel; opening a discharge valve of the extraction tank to discharge the circular organic and organic regenerative wastewater and the extracted crude zirconium oxychloride solution, testing the discharged solution, extracting the solution through multiple stages, and discharging the extracted crude zirconium oxychloride solution from the front end of the extraction tank; concentrating and crystallizing the solution; and putting the crystallized material into a suction filter tank, rinsing the crystallized material, then drying the rinsed material by a centrifugal machine, and packing the dried material. The process has the advantages of shortening the process flow, avoiding the introduction of alcohol reagent in an extraction system, improving the stability of the extraction system, reducing the volatility and water solubility of an extracting agent, reducing the consumption of organic reagent, improving the working environment, reducing the treatment difficulty of wastewater, and saving the production cost.

Owner:JIANGXI KINGAN HI TECH

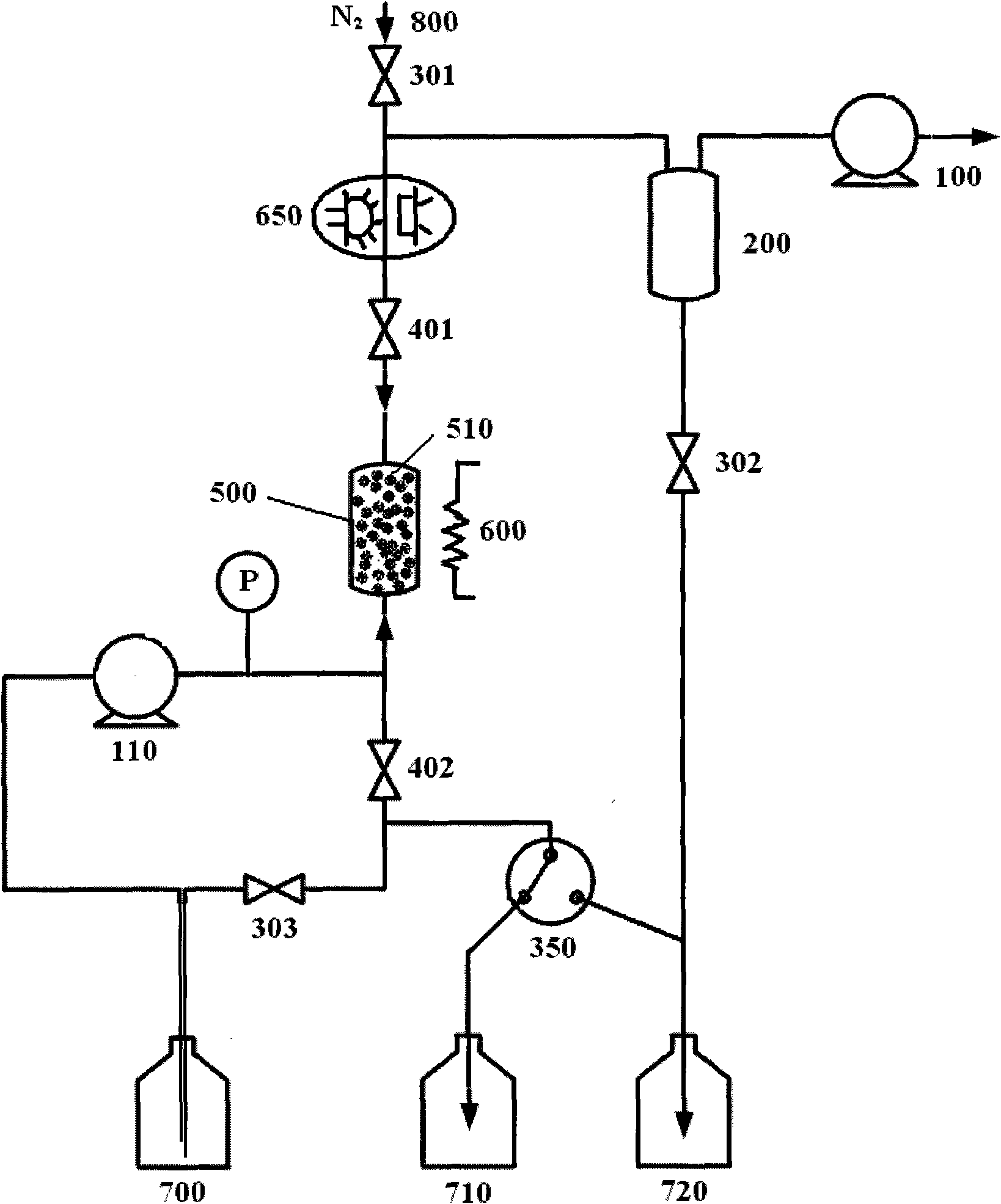

Pressing solvent extraction device for absorbing extracting solvent under negative pressure

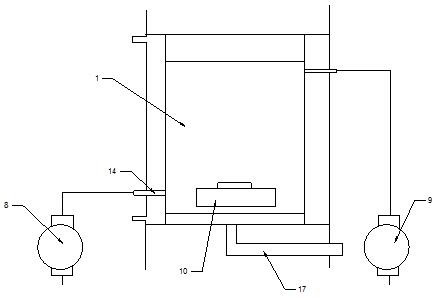

ActiveCN102100977ALow compressibilityShort transition timeSolid solvent extractionControl systemHigh pressure

The invention relates to a pressing solvent extraction device for absorbing an extracting solvent under negative pressure. In the device, a small air extracting pump serves as a negative pressure source; most of gases in an extraction pool and samples in the extraction pool are exhausted; the extracting solvent is absorbed into a sample pool and filled in the sample pool; the extraction pool is heated to a specified temperature; and pressure is supplemented by a high-pressure transfusion pump, so that high pressure intensity required in the extraction process is met. Gases in the extraction pool and the extracted samples can be effectively exhausted by the entrance mode of the solvent, so that the samples are soaked completely with the extracting solvent, and extraction efficiency and extraction repeatability can be obviously improved. Pressure reduction by exhaust and drainage is not required in the extraction heating process. The technology is applied to a pressing solvent extraction instrument, so a high-pressure release valve and a corresponding control system in the pressing solvent extraction instrument can be saved, cost of equipment is reduced, extraction performance is improved, and secondary pollution to the environment is reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ionic liquid-molecular solvent composite extraction agent and application thereof

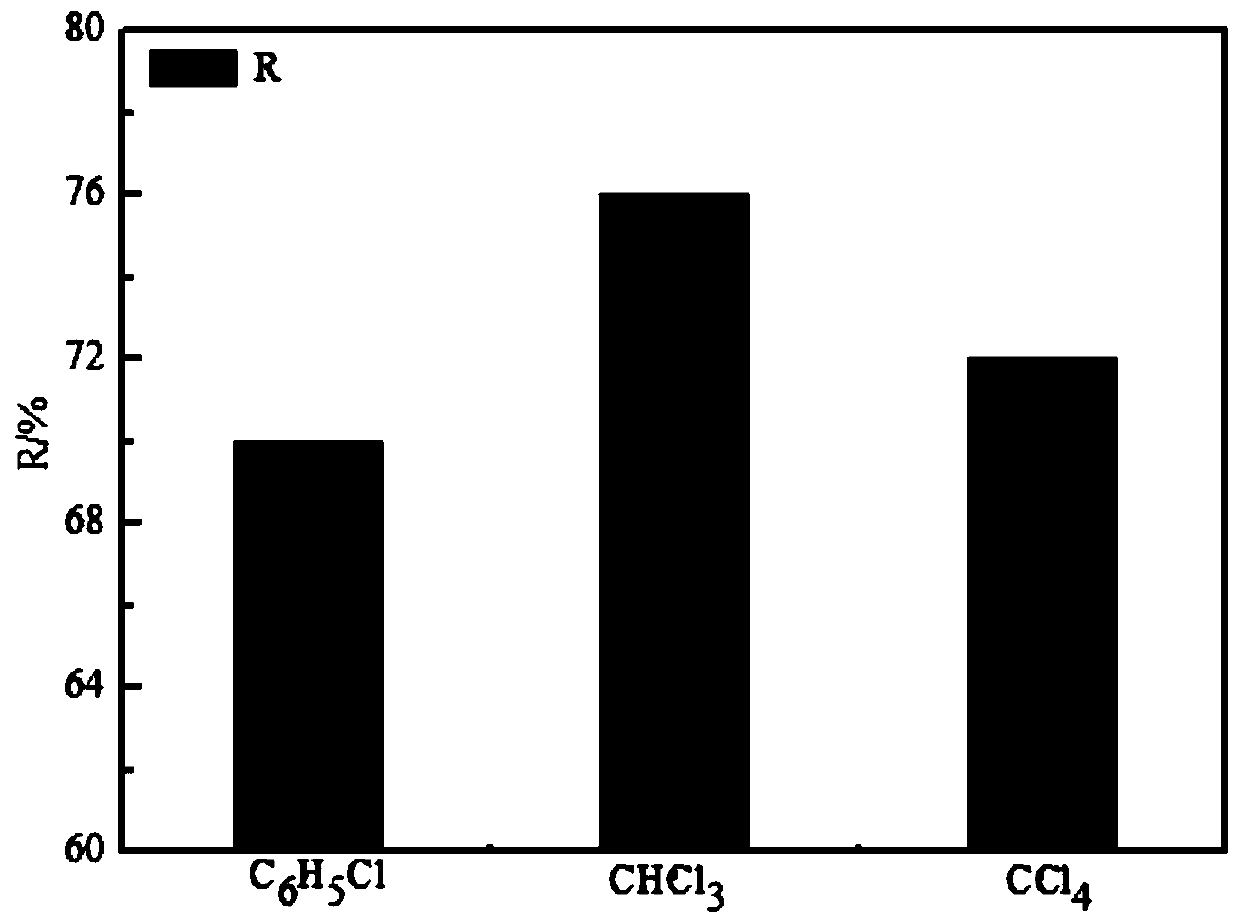

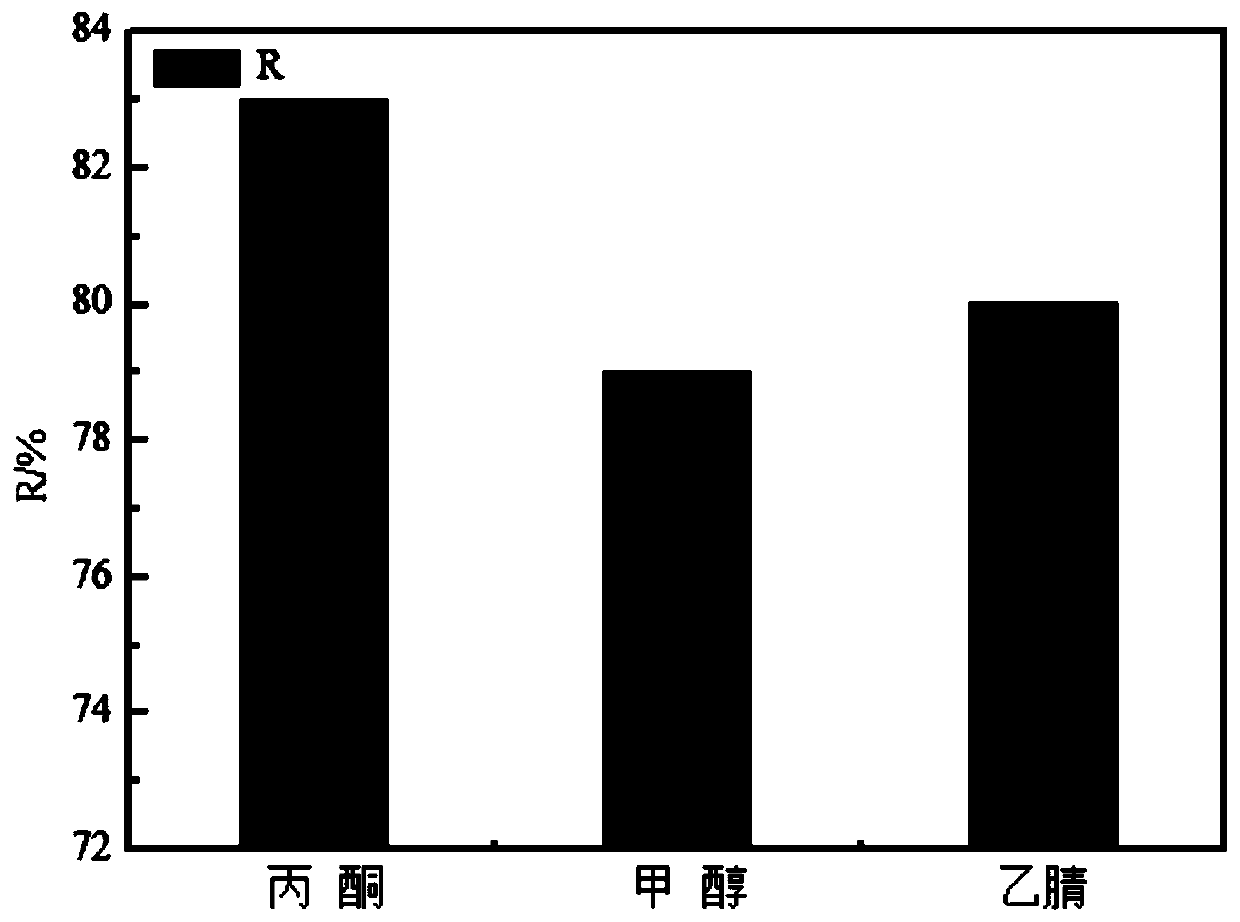

ActiveCN108640193AHas extraction propertiesLow viscosityGroup 5/15 element organic compoundsWater contaminantsHalogenChloride

The invention provides an ionic liquid-molecular solvent composite extraction agent and application thereof. The composite extraction agent is prepared from ionic liquid and a molecular solvent. The volume ratio of the ionic liquid to the molecular solvent is (10-0.6):1. Cations of the ionic liquid are imidazolium cations or pyridine cations. Anions of the ionic liquid are halogen anions or nitricacid anions or tetrafluoroboric acid anions or phosphofluoric acid anions or aluminum chloride anions or zinc trichlorine anions. The organophosphorus extraction efficiency of the composite extraction agent prepared from the ionic liquid and the molecular solvent can reach 76%-97%.

Owner:HEBEI UNIV OF TECH

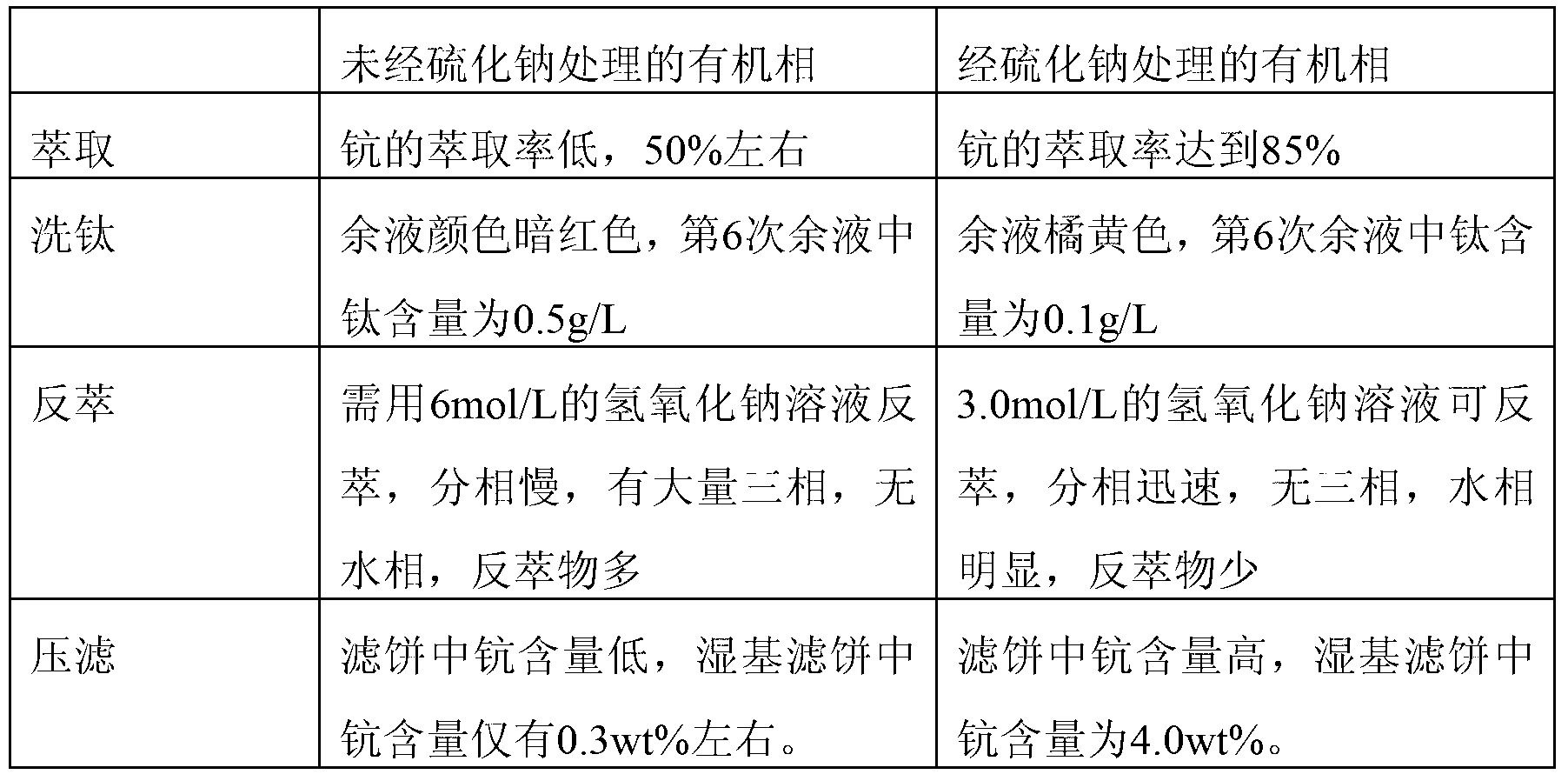

Recycling method of organic phase used for extracting scandium

ActiveCN103233134AHigh extraction performanceLong cycle lifeProcess efficiency improvementPhase splittingTitanium

The invention relates to a recycling method of an organic phase used for extracting scandium. The method comprises the following steps of: adding a sodium sulfide solution into the organic phase and mixing; performing phase splitting; discharging a water phase; adding a sulfuric acid solution into the rest of organic phase; washing the acidified organic phase with water; and using the acidified organic phase to extract scandium. The organic phase treated by using the method can be recycled, the subsequent efficiencies of titanium washing and reverse extraction processes also can be improved, most of titanium impurities can be washed off from the organic phase, and the efficiency of reverse extraction can be obviously improved; and the organic phase can be totally reversely extracted by using 3mol / L of industrial alkali, the phase splitting efficiency is rapid, and the scandium content of an obtained alkali cake is high.

Owner:桃江瑞龙金属新材料有限责任公司

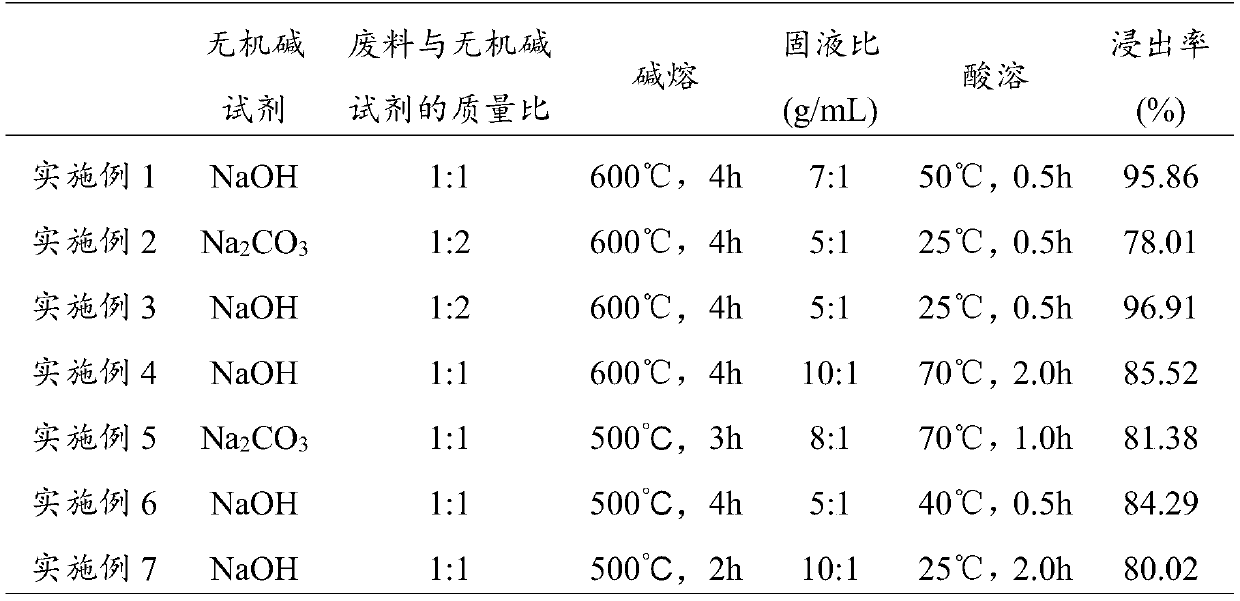

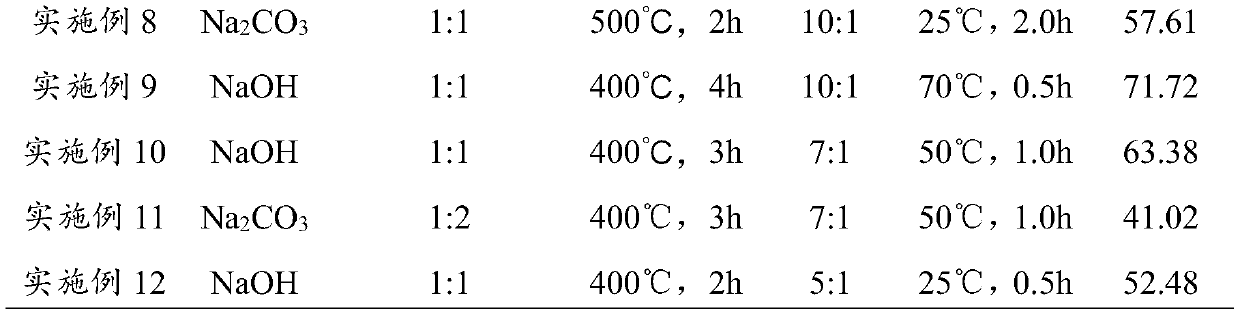

Method for recycling rare earth in cerium-doped lutetium yttrium oyorthosilicate waste material

ActiveCN110306059AGood extraction performanceHigh recovery rateProcess efficiency improvementEtherAcid dissolution

The invention provides a method for recycling rare earth in cerium-doped lutetium yttrium oyorthosilicate waste material, and belongs to the technical field of comprehensive recycle and utilization ofrare-earth resources. The method for recycling the rare earth in the cerium-doped lutetium yttrium oyorthosilicate waste material comprises the following steps that the cerium-doped yttrium lutetiumoyorthosilicate waste material and an inorganic alkali reagent are mixed, and alkali fusion is carried out to obtain enriched material; the enriched material and an acid solution are mixed, and acid dissolution is carried out to obtain an acid leaching solution; the acid leaching solution is extracted by adopting an extracting agent solution to obtain a rare earth extracting solution; reverse extracting is carried out on the rare earth extracting solution to obtain and recycle rare earth material, wherein the extracting agent solution comprises an ether amide functional ionic liquid and a mixed solution of an additive and a diluent. According to the method, the structure of the cerium-doped lutetium yttrium oyorthosilicate waste material is destroyed in the alkali fusion process, the acidconsumption in the acid dissolution process is reduced, by adding the ether amide functional ionic liquid, the extraction performance of the rare earth is improved, the operation is simple and convenient, the cost is low, and the method is suitable for industrial production.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

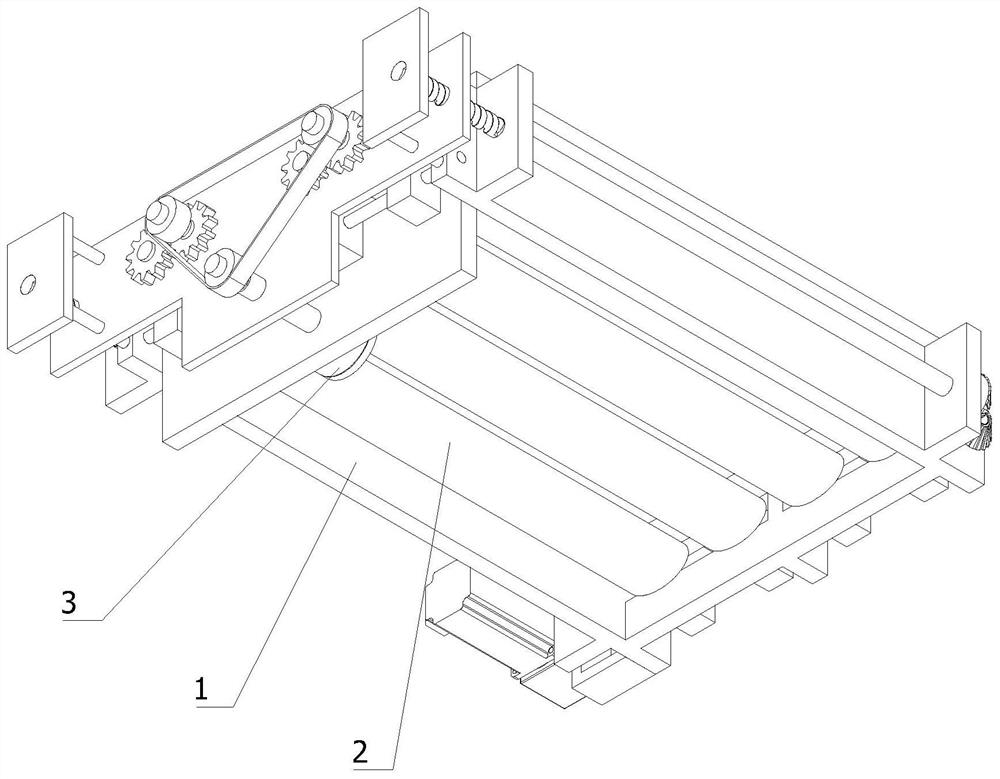

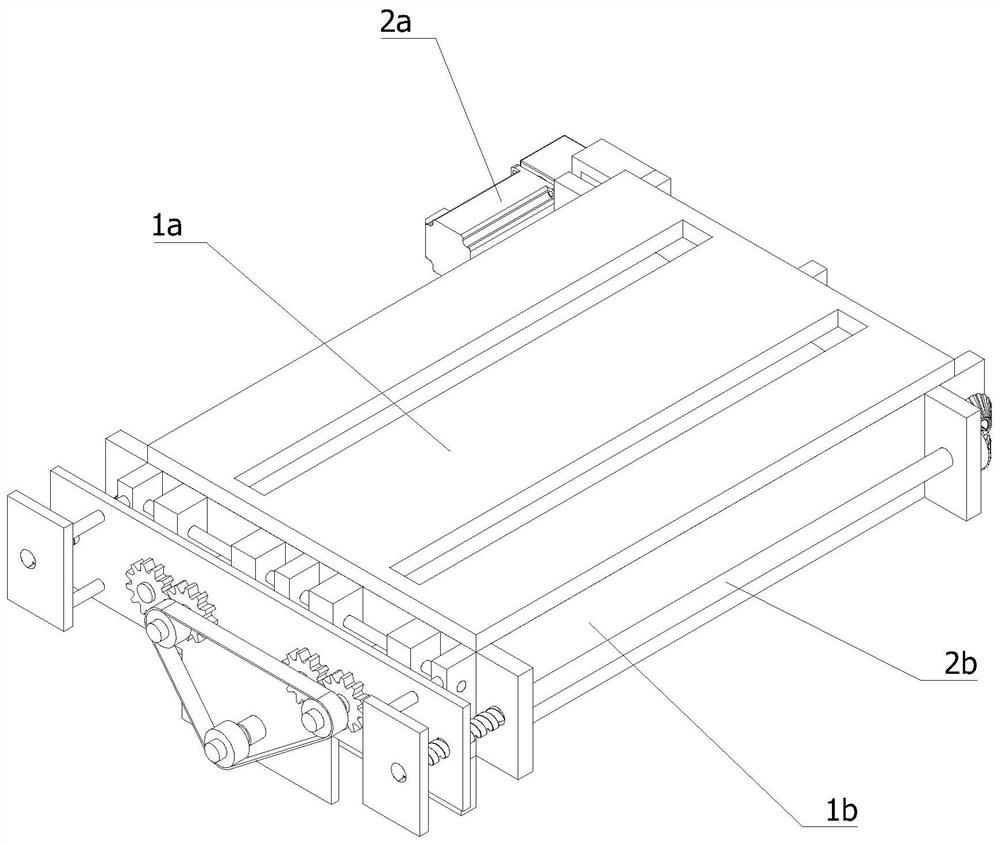

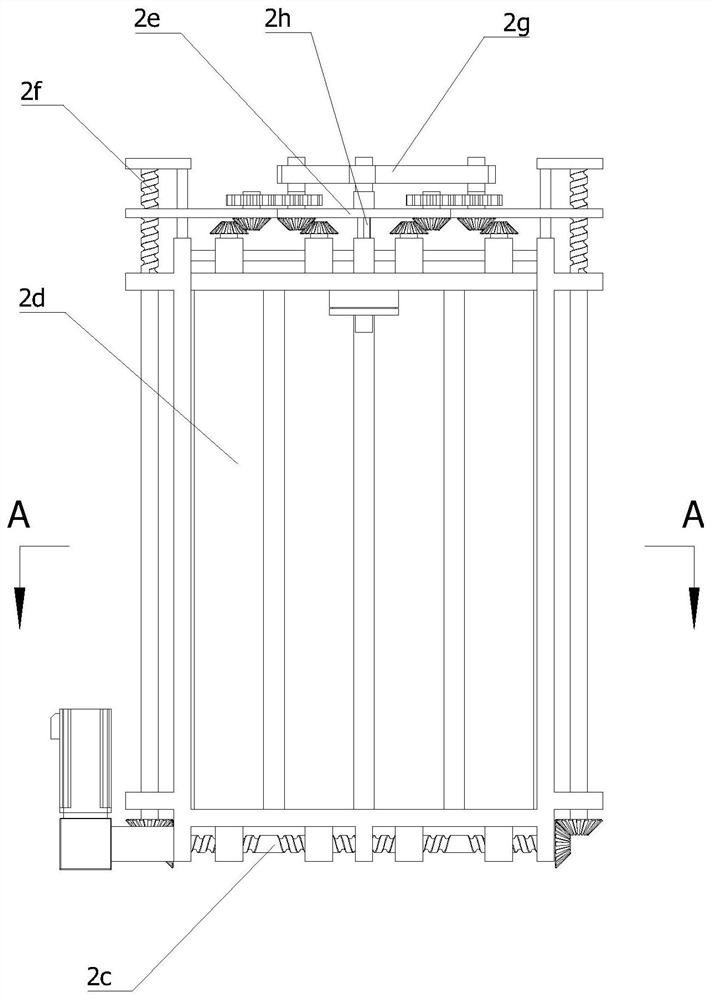

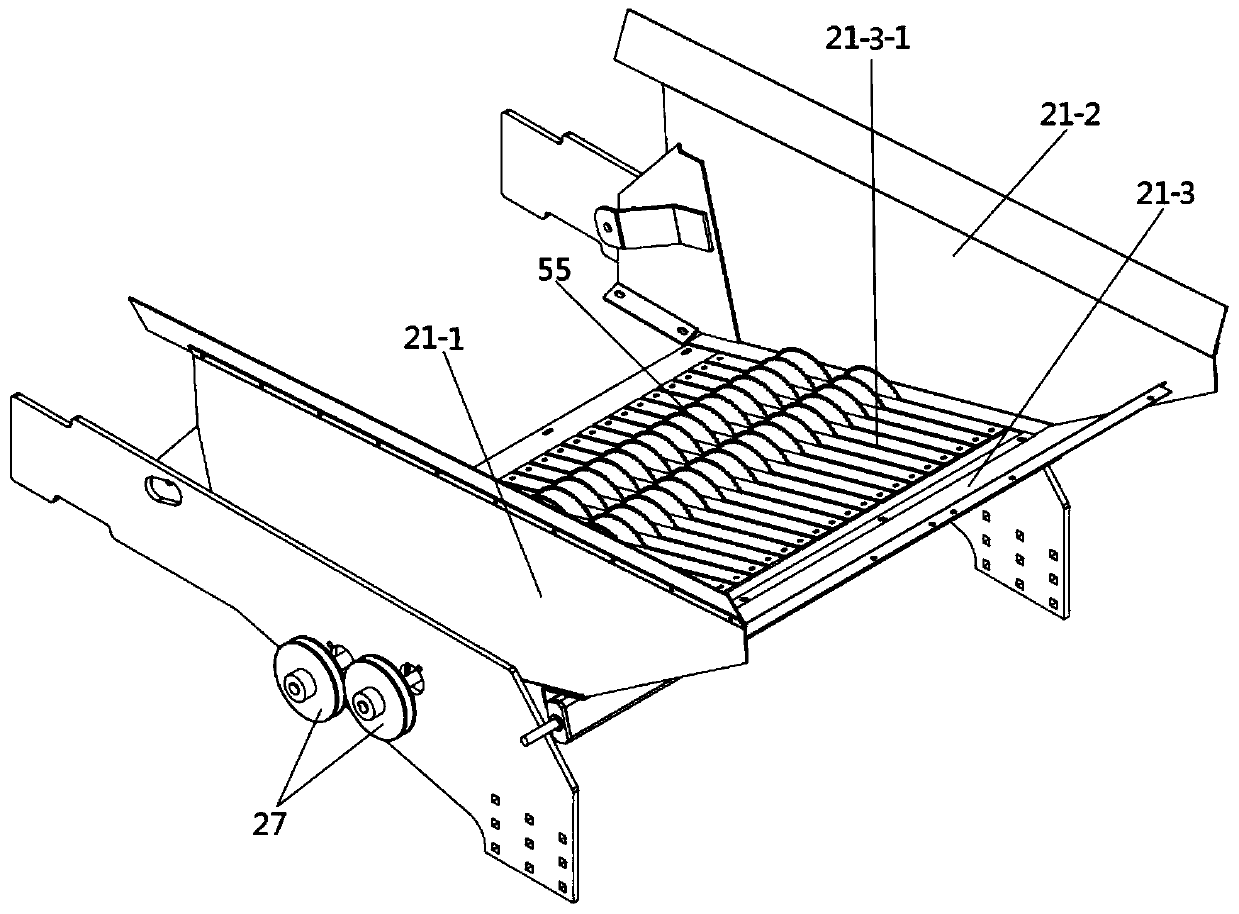

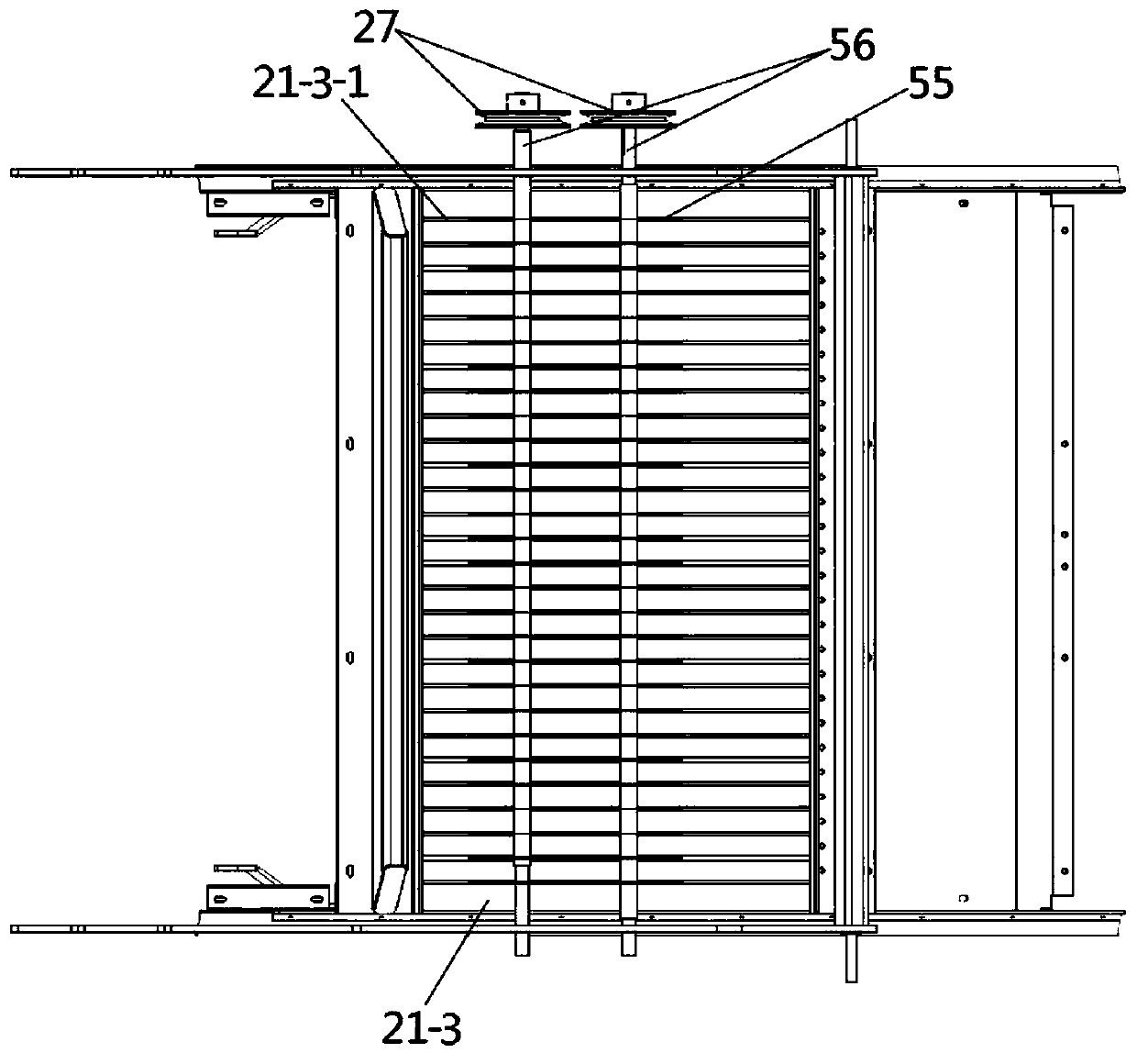

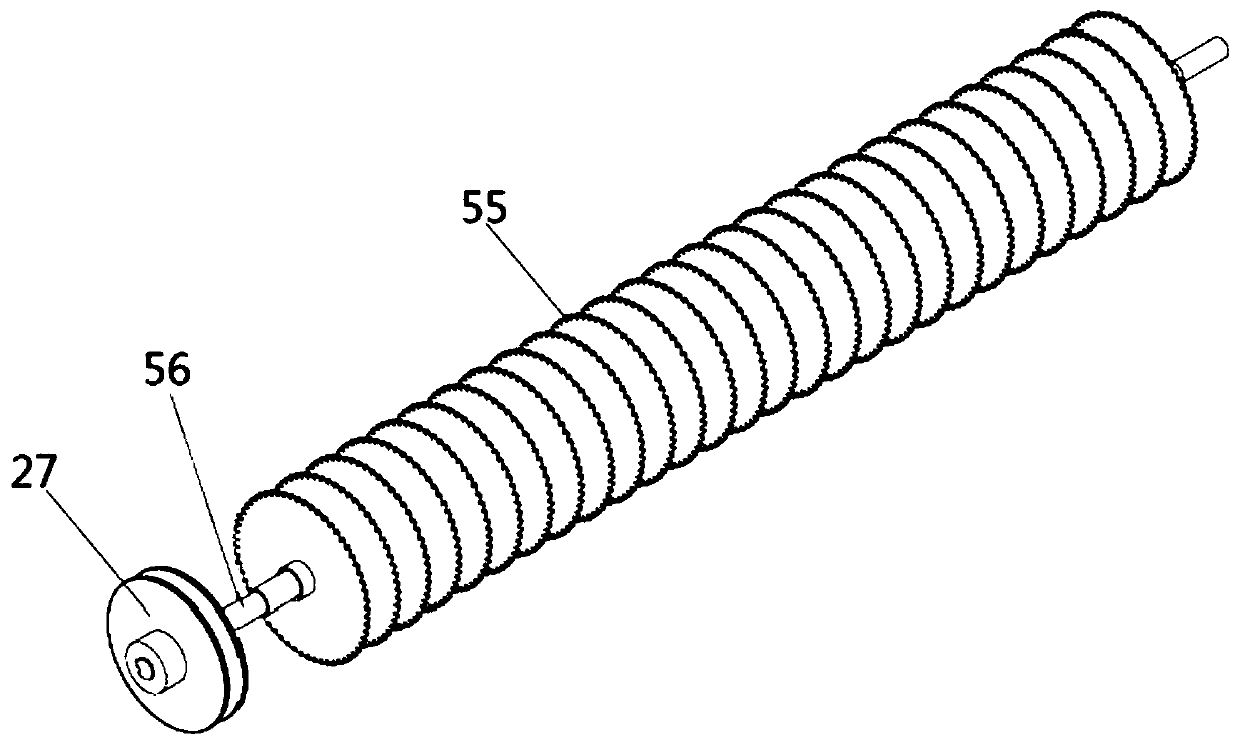

Automatic honeysuckle picking machine

InactiveCN112335402AGood extraction performanceGuaranteed rotary drive effectPicking devicesControl engineeringControl theory

The invention relates to the technical field of automatic honeysuckle picking devices, in particular to an automatic honeysuckle picking machine. The machine comprises a support, a picking mechanism,a swing controller, a screening filter and a picking machine body. The support is fixed to the picking machine body and used for installing the picking mechanism, the swing controller and the screening filter. The picking mechanism is installed on the support and used for picking honeysuckle. One end of the swing controller is rotationally connected with the support, and the other end is fixedly connected with one end of the screening filter for controlling the screening filter to reciprocate; the screening filter can be movably and elastically connected with the support along the length direction of the support and is used for screening the honeysuckle; and the picking machine body is used for providing drive and energy for the picking mechanism and the swing controller and collecting thehoneysuckle picked by the picking mechanism. According to the scheme, the distance between each set of picking rollers can be conveniently adjusted, and meanwhile synchronous rotation of the pickingrollers can be guaranteed all the time.

Owner:青岛爱婴坊商贸有限责任公司

20-50% website percentage-based website displacement grating anti-fake method

InactiveCN108830774AImprove concealmentEasy to identifyImage data processing detailsGratingImage synthesis

The invention discloses a 20-50% website percentage-based website displacement grating anti-fake method. The method comprises the following steps of: (1) manuscript preparation and preprocessing; (2)website displacement; (3) website percentage-grade improvement; (4) image synthesis; and (5) simulation and decoding. According to the method, a displacement algorithm and a website percentage algorithm are designed for the encrypted areas with website percentage of 0.2-0.5, so that the stealthiness and extraction recognizability of anti-fake information are improved and the operation difficulty is reduced.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

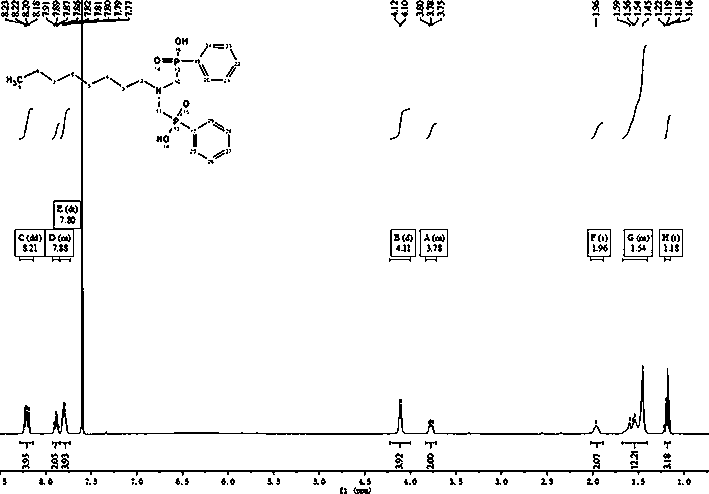

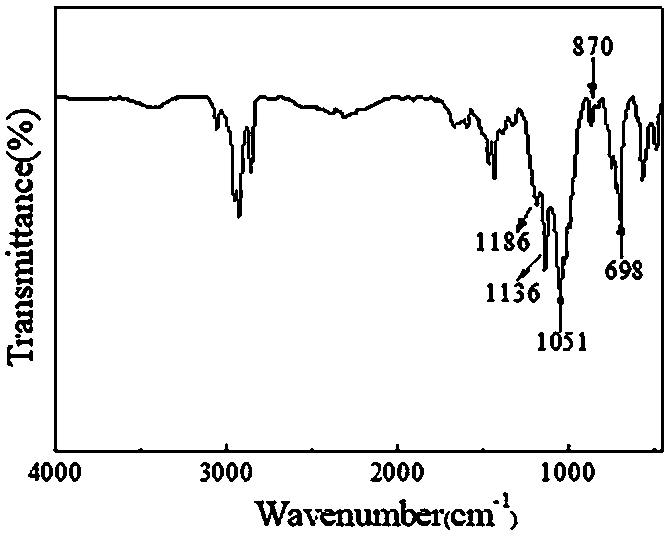

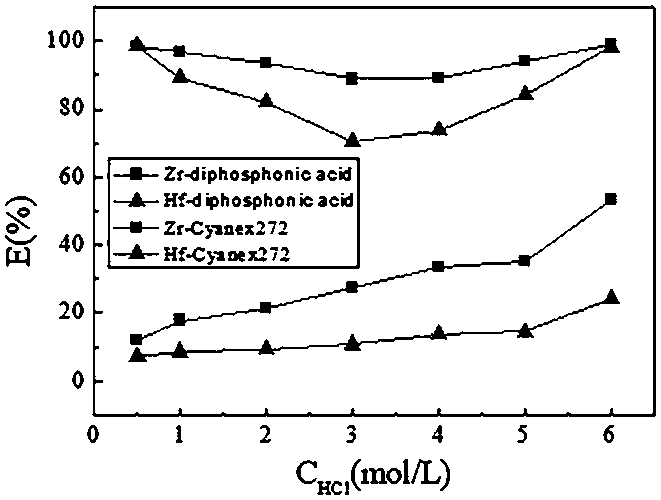

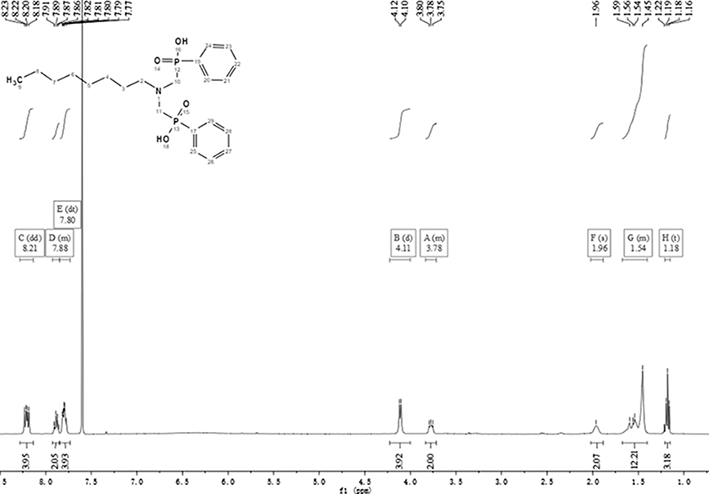

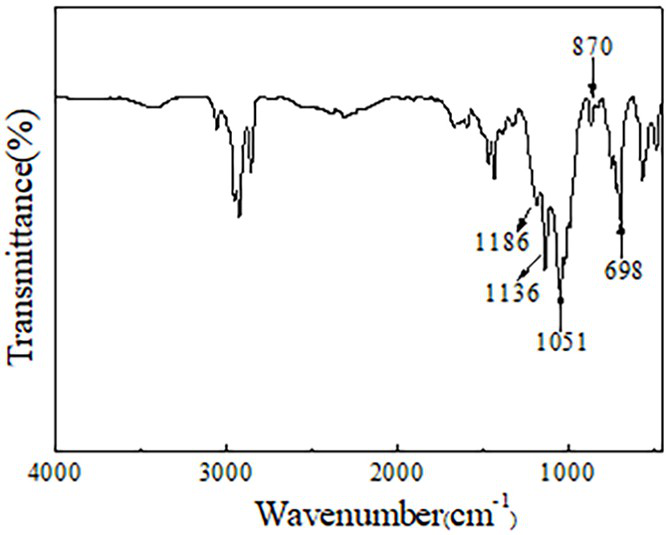

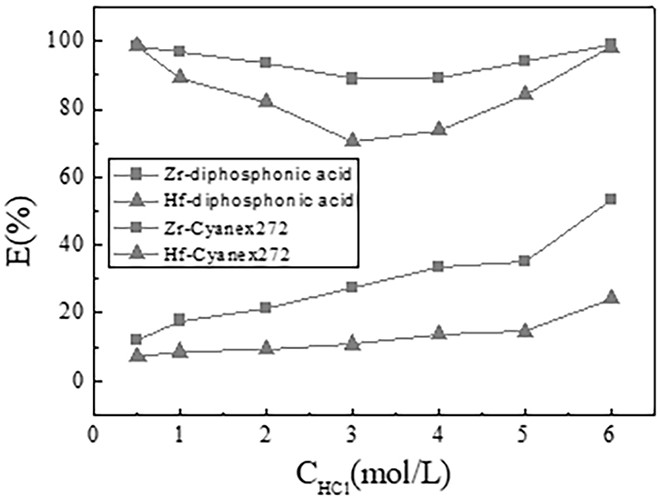

Diphosphoric acid extractant for extracting and separating zirconium and hafnium, and preparation method thereof

ActiveCN110746454AGood choiceEasy extractionGroup 5/15 element organic compoundsProcess efficiency improvementPhosphoric acidHafnium

The invention discloses a novel diphosphoric acid extractant N,N-n-octylamine di(methylene phenyl hypophosphorous acid) for extracting and separating zirconium and hafnium, and a preparation method thereof. The extractant has the advantages of convenience in synthesis, good oil solubility and excellent stability. The N,N-n-octylamine di(methylene phenyl hypophosphorous acid) has very strong extraction capacity on zirconium and hafnium, and has a far higher extraction rate than a common acidic organic phosphorus extractant under the same conditions. The diphosphoric acid extractant preferentially extracts zirconium while ensuring the extraction rate, so the problems of low zirconium-hafnium extraction rate and poor separation effect are solved.

Owner:UNIV OF JINAN

Method for supercritical CO2 extraction of entada phaseoloides

InactiveCN114028447AEffectively retain the original propertiesLow extraction temperaturePlant ingredientsEntada phaseoloidesOrganic solvent

The invention discloses a method for supercritical CO2 extraction of entada phaseoloides. The method comprises the following steps: drying peeled entada phaseoloides powder at 65 DEG C or below for 6-12 hours; performing supercritical CO2 extraction; and carrying out two-stage decompression separation on the obtained extract to respectively obtain entada phaseoloides extracting solutions. Compared with the prior art, the extraction temperature is low, the extraction speed is high, the extraction rate is high, and the original properties of substances are effectively reserved; the method has the advantages of no organic solvent residue, high selectivity, high yield, low toxicity and the like, and has no adverse effect on human and environment; and the problem of oxidative degradation in the production process is effectively prevented.

Owner:湖南汉华京电清洁能源科技有限公司

Peanut fruit stem picking device for peanut harvester

PendingCN111183803ACause some damagesCause back and forthMowersDigger harvestersMultiple fruitHorticulture

The invention discloses a peanut fruit stem picking device for a peanut harvester and belongs to the technical field of peanut harvesters. The peanut fruit stem picking device comprises a peanut fruitreceiving guide groove. A peanut fruit stem picking mechanism is disposed on the guide groove bottom wall of the peanut fruit receiving guide groove and comprises a fruit stem supporting groove and at least one fruit stem picking tray, wherein the fruit stem picking tray comprises multiple fruit stem picking saws and a fixation shaft of the fruit stem picking saws, each fruit stem picking saw isa round zigzag-shaped blade, the fruit stem picking saws are at an interval fixed on the fixation shaft of the fruit stem picking saws, a row of groove holes of the fruit stem picking saws are at an interval formed in the guide groove bottom wall of the peanut fruit receiving guide groove, the row of groove holes of the fruit stem picking saws are disposed back and forth in parallel, the fixationshaft of the fruit stem picking saws is horizontally disposed under the peanut fruit receiving guide groove, the left end and the right end of fixation shaft of the fruit stem picking saws are supported on the left side and the right side of the harvester respectively, and saw teeth of each fruit stem picking saw in each fruit stem picking saw groove hole, which is embedded at a corresponding position of the upper part of the fruit stem picking saw of the fruit stem picking try, is inclined to a rotation direction. The peanut fruit stem picking device is characterized by low energy consumption, a simple and practical structure, high working reliability and the like.

Owner:河北永发鸿田农机制造有限公司

Ultrasonic method for desulfurizing ethylene cracking C9

InactiveCN113797869AIncrease the speed of diffusionImprove desulfurization efficiencyTreatment with plural serial refining stagesLiquid solutions solvent extractionChemical reactionUltrasound techniques

The invention relates to an ultrasonic method for desulfurizing ethylene cracking C9, wherein the method comprises the following steps: an adsorption process: starting an adsorption bed ultrasonic device, and carrying out adsorption desulfurization on C9 through an adsorption bed; an oxidation extraction process: starting a primary extraction tower ultrasonic device, adding ionic liquid / hydrogen peroxide into a primary extraction tower, and carrying out oxidation extraction desulfurization; and an extraction strengthening process: starting an ultrasonic device of a secondary extraction tower, adding a multi-component compound extraction agent into the secondary extraction tower, and carrying out extraction desulfurization. The ultrasonic technology is introduced into C9 desulfurization, the chemical reaction speed and the extraction depth are increased, in addition, the three-stage desulfurization process of adsorption, oxidation extraction and re-extraction is adopted, the desulfurization efficiency and selectivity are high, and the extraction performance is effectively enhanced.

Owner:天津天大天海化工新技术有限公司

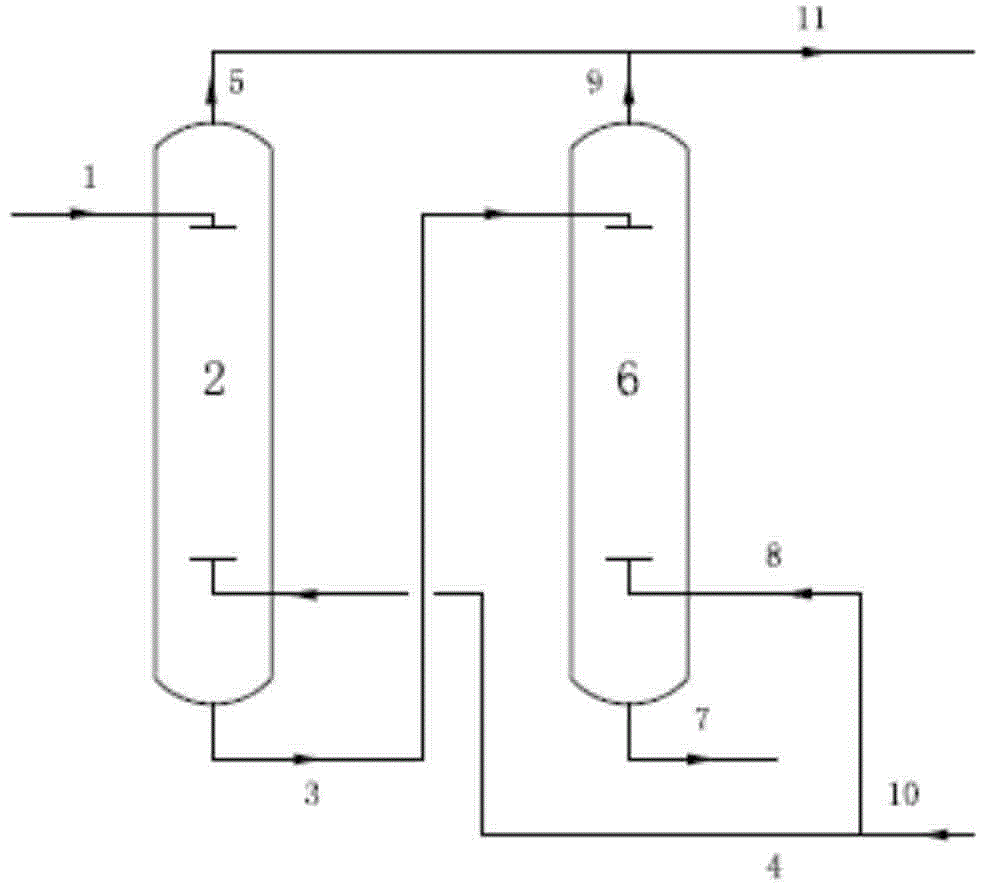

Method for realizing rapid extraction of organic compounds

PendingCN111672157AAchieve recyclingFast gatheringCounter-current extractionLiquid solutions solvent extractionPeristaltic pumpSimple Organic Compounds

The invention relates to a method for realizing rapid extraction of organic compounds. The method utilizes an extraction tower and a recovery tower, the extraction tower comprises an extraction cylinder, a light component cylinder arranged at the upper end of the extraction cylinder and a heavy component cylinder arranged at the bottom of the extraction cylinder, the extraction tower is connectedwith the recovery tower through an output end at the bottom of the heavy component cylinder, the bottom output end of the recovery tower is connected to one input end of the extraction cylinder through a pipeline, a separation tank and a porous membrane column arranged in the separation tank are arranged in the extraction cylinder, the top end of the porous membrane column is connected with a peristaltic pump through a circulating pipe, and the bottom of the separation tank is connected with the peristaltic pump through a three-way valve. The rapid extraction method provided by the invention has the advantages of cyclic and continuous operation, high phase separation speed and the like.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

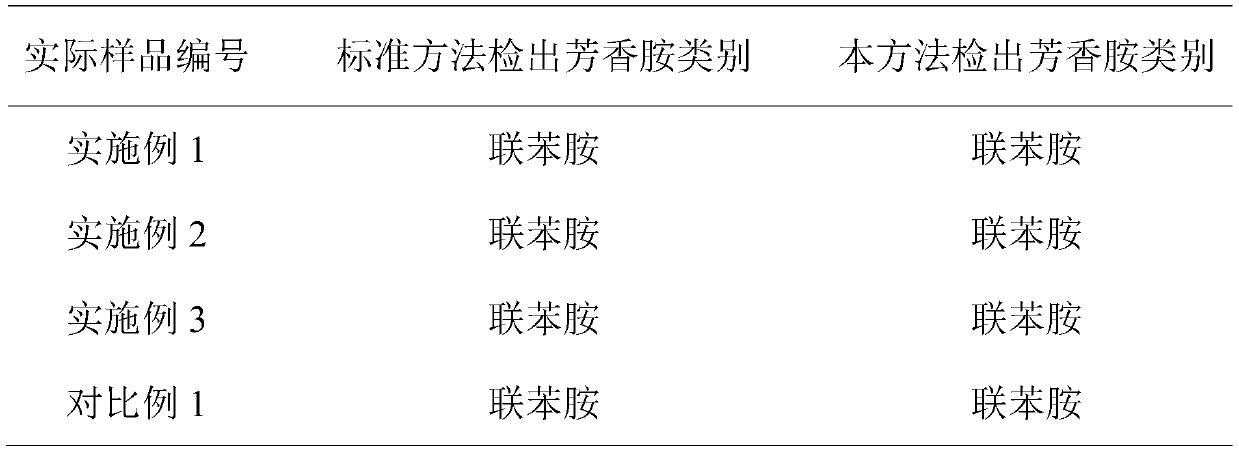

Method for detecting azo dyes in crocodile leather products and evaluation system constructing method

InactiveCN110261523AGood extraction performanceHigh recovery rateComponent separationCentrifugationGas chromatography–mass spectrometry

The invention relates to a method for detecting azo dyes in crocodile leather products and an evaluation system constructing method. The method for detecting the azo dyes in the crocodile leather products comprises the following steps that: a leather sample and a preheated citrate buffer solution are mixed, so that a sample treatment liquid is obtained, primary heat preservation is performed on the sample treatment liquid, a sodium hydrosulfite aqueous solution is added into the sample treatment liquid, and the sodium hydrosulfite aqueous solution and the sample treatment liquid are mixed uniformly, and secondary heat preservation is performed on an obtained mixed liquid, and the mixed liquid cools to room temperature, so that a reducing liquid can be obtained; a dispersing liquid and an extracting liquid are added into the reducing liquid, and the dispersing liquid, the extracting liquid and the reducing liquid are uniformly mixed, an obtained mixed liquid stands still, and is subjected to centrifugation, an underlying organic phase is taken and is adopted as a liquid for testing, and the volume ratio of the reducing liquid, the dispersion liquid and the extracting liquid is (490-510):(80-120):(18-22); and the liquid for testing is subjected to gas chromatography-mass spectrometry analysis. Compared with a traditional column chromatography extraction, the detection method disclosed by the invention is advantageous in improved sample recovery rate, thereby improving the detection accuracy of forbidden azo dyes in crocodile leather products.

Owner:GUANGDONG TESTING INST OF PROD QUALITY SUPERVISION

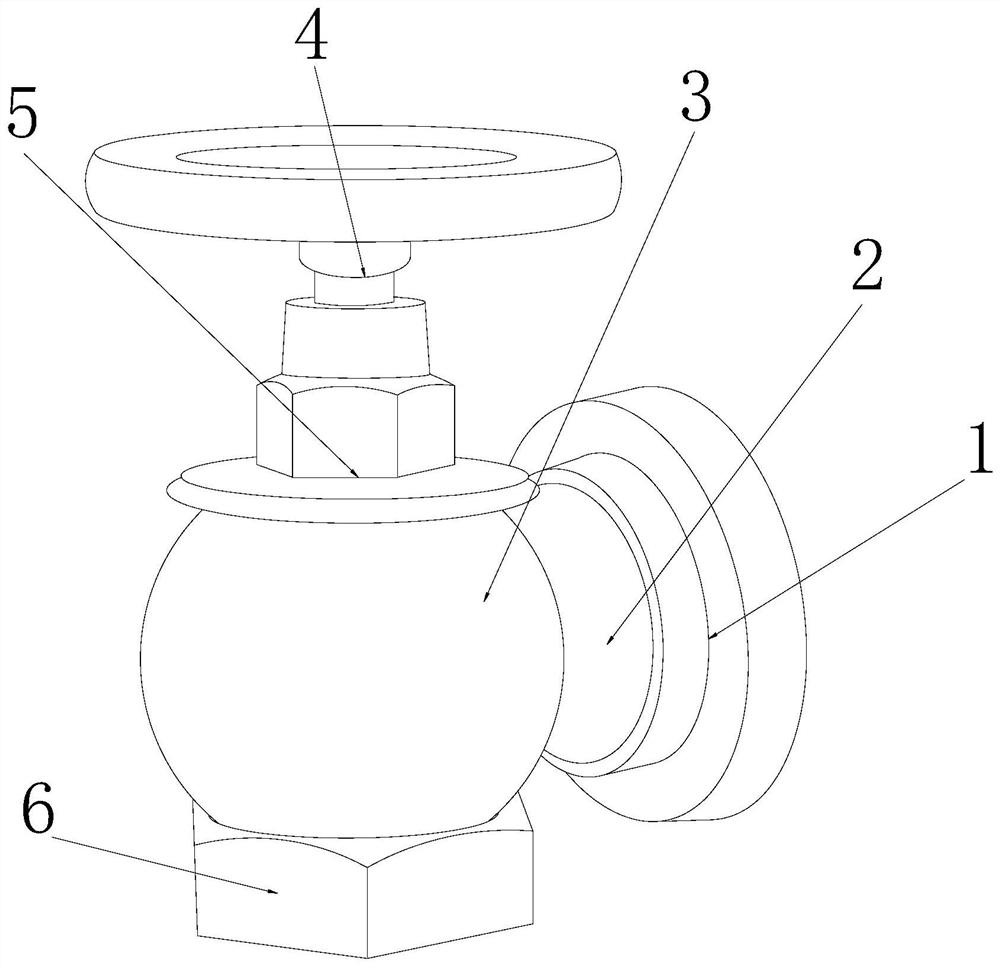

Fire valve

InactiveCN112717316AAmplify the effect of debugging operationImprove extraction performanceFire rescueValve housingsWater wheelWater source

The invention discloses a fire valve which structurally comprises a hoop sleeve disc base, a water drainage pipe end groove, a star-jet propeller ball valve, a handle wheel carrier, a pressure flow support seat and a nut base block. According to the fire valve, through cooperation of the water drainage pipe end groove and the star-jet propeller ball valve, a short pipeline groove and an outer ball valve shell cooperate with a damping bracket rod and spiral flow guide stamping in a star-jet nozzle frame to improve the flow dividing efficiency and the continuously-supplied pressure impulse, the continuity and stability of the whole pipeline butt joint flow are guaranteed, and the phenomenon that improvement is insufficient due to too large water pressure is avoided; and repeated acting force of spiral stamping of the star-jet nozzle frame and the extraction operation effect of a water wheel type damping bracket rod framework are guaranteed, a fire ball valve is in butt joint with a fire-fighting truck for water supply and supplementing, the fire-fighting projection radian output by a pipeline is high, and the effect of converging and pressurizing a small-flow converging opening is achieved at the water source end.

Owner:广州建琴贸易有限公司

A kind of bisphosphoric acid extractant for extracting and separating zirconium and hafnium and preparation method thereof

ActiveCN110746454BGood choiceEasy extractionGroup 5/15 element organic compoundsProcess efficiency improvementO-Phosphoric AcidPhysical chemistry

The invention discloses a novel bisphosphoric acid extractant N,N-n-octylamine di(methylene phenylphosphinic acid) for extraction and separation of zirconium and hafnium and a preparation method thereof. The extractant is easy to synthesize, has good oil solubility and good stability. N, N-n-octylamine di(methylene phenylphosphinic acid) has a strong extraction ability for zirconium and hafnium, and the extraction rate is far higher than that of common acidic organic phosphorus extractants under the same conditions. While ensuring the extraction rate, this bisphosphoric acid extraction agent preferentially extracts zirconium, which solves the problems of low extraction rate of zirconium and hafnium and poor separation effect.

Owner:UNIV OF JINAN

A supercritical co 2 Extracted Entrained Pharmaceutical Methods

ActiveCN111013188BImprove solubilityAvoid formingPharmaceutical product form changeSolid solvent extractionMedicinal herbsActive agent

The invention discloses a new type of entrainment pharmaceutical method based on supercritical CO2 extraction, which belongs to the technical field of supercritical pharmaceuticals, and can realize that most of the entrainer is injected into the centrifugal slow-release ball through a new type of entrainer mixing method, and less Part of it is pre-mixed with supercritical CO2. During the extraction, the injected entrainer is slowly released into the medicinal powder and fully contacted by extrusion through centrifugal rotation. At the same time, the medicinal powder is driven to turn over continuously. The reaction is fully and comprehensively carried out under the atmosphere, which significantly strengthens its extraction performance and improves its extraction efficiency. At the same time, it enhances the solubility of the active ingredients in the medicinal material and the sensitivity to temperature and pressure, so that the separated components can be separated from the circulating gas through temperature and pressure. Separated to avoid the high energy consumption of gas recompression, it can even be used as a co-surfactant to facilitate the formation of supercritical fluid microemulsion, which has great advantages in extracting biologically active components in medicinal materials.

Owner:JIANGSU GAOKE PHARM EQUIP CO LTD

A method for detecting bisphenol compounds and their derivatives based on extraction technology of metal organic framework nanomaterials

The invention provides a method for detecting bisphenol compounds and derivatives thereof based on the extraction technology of metal organic framework nanomaterials. The nanomaterial is NH 2 ‑MIL‑101(Fe) materials, bisphenols and their derivatives are log K ow Bisphenol compounds and their derivatives within the range of 1.17 to 3.96 are called BPs. The method comprises the following steps: S1: the adsorbent NH 2 ‑MIL‑101(Fe) is added to the sample containing BPs and the pH of the sample is adjusted within the range of 2.0 to 7.0, and then ultrasonically treated for 1.0 to 5.0min to obtain the ultrasonic liquid; S2: the ultrasonic liquid obtained in step S1 Perform centrifugation to obtain liquid A, remove the supernatant M of liquid A to obtain liquid B; S3: use the eluent to vortex elute the liquid B obtained in S2 for 1.0-5.0 minutes, and then perform centrifugation to obtain liquid C , collecting the supernatant N of the liquid C, and the eluent is one of methanol, acetonitrile and acetone; S4: after constant volume of the supernatant N in step S3, perform chromatographic analysis and quantification.

Owner:WENZHOU MEDICAL UNIV

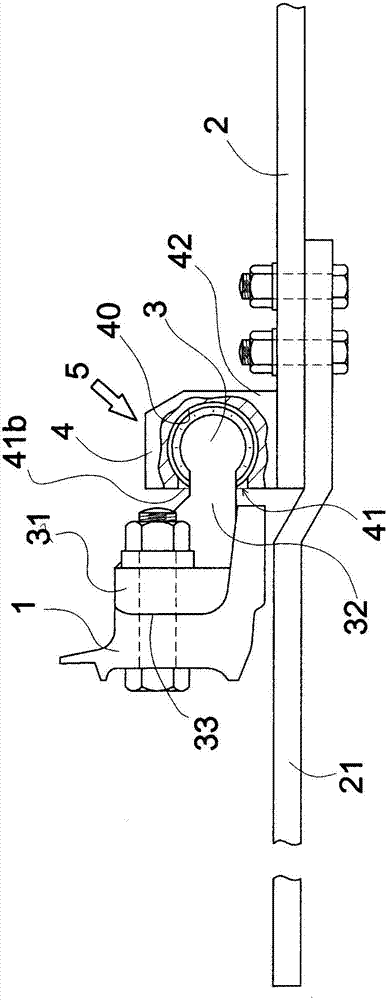

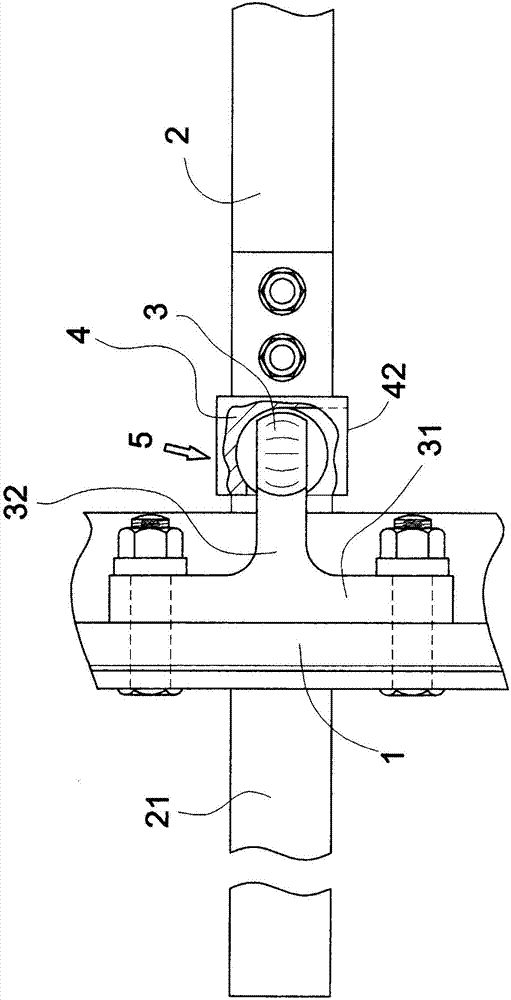

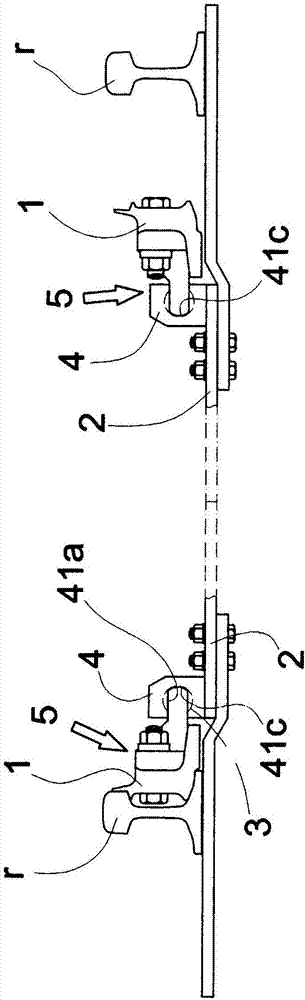

Switch rail of turnout junction for railway and connection device for rotary handle

ActiveCN106917327AGood extraction performanceNot easy to pull outRail switchesElectrical and Electronics engineeringEngineering

The present invention provides a switch rail of a turnout junction for a railway and connection device for a rotary handle. The switch force generated when the switch rail is switched from the rotary handle and the switch rail is configured to cause vibration of the switch rail when the vehicle passes through, the bolts and nuts are fixed on the U-shaped metal buckle and the connection plate to cause the loosening and dropping of each nut to separate the switch rail from the rotary handle to finally cause the possibility of the train derailing. the connection device having the switch rail 1 and the rotary handle 2 and the switch rail 1 is employed, and a concave part 4 is formed by outside embedding locking portion 40 corresponding to the bump part 3 formed at the installation portion 5 of the switch rail 1 and the rotary handle 2 to connect together through a concave-convex tabling structure.

Owner:曹大明 +3

Process for preparing high-purity zirconium oxychloride

Owner:JIANGXI KINGAN HI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com