Preparation method for metal wire solid-phase micro-extraction fiber of noble metal nanometer material-ionic liquid composite functional coating

A technology of ionic liquids and nanomaterials, applied in the field of solid-phase microextraction fibers, can solve problems such as the fixation of difficult and precious metal nanomaterials, and achieve the effects of enhancing extraction performance, improving stability, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

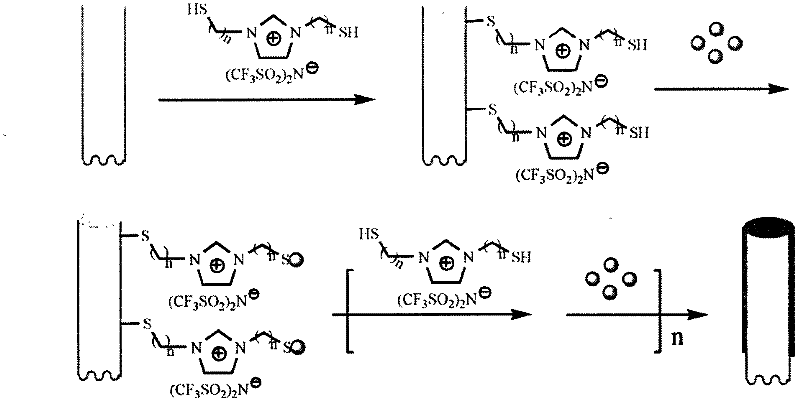

[0023] Example 1: Preparation of gold nanoparticle-imidazole-based ionic liquid composite extraction coating metal wire solid phase microextraction fiber

[0024] It includes the following three steps: A, B, and C:

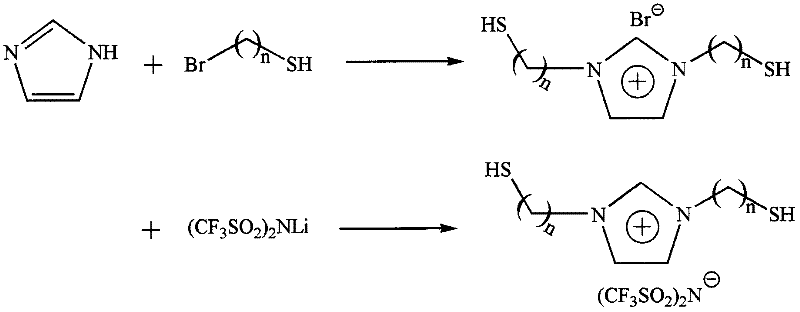

[0025] A. Preparation of disulfhydryl ionic liquid

[0026] 0.100mol imidazole was mixed with 0.200mol 3-bromopropanethiol, protected by nitrogen, stirred at 80 degrees Celsius for 48 hours, acetone was recrystallized twice to obtain imidazolyl bromide ionic liquid with two mercapto groups; 0.050mol imidazolyl Bromide ionic liquid with 0.060mol NH 4 PF 6 The aqueous solution is mixed, stirred at room temperature for 24 hours, and the precipitate is dried and recrystallized twice with acetone to obtain a high-temperature resistant imidazole-based hexafluorophosphate ionic liquid.

[0027] B. Surface pretreatment of stainless steel wire

[0028] First, polish the surface of one end of the stainless steel wire with fine sandpaper, then ultrasonically clean with water and etha...

Embodiment 2

[0031] Example 2: Preparation of silver nanoparticle-imidazole-based ionic liquid composite extraction coating metal wire solid phase microextraction fiber

[0032] It includes the following three steps: A, B, and C:

[0033] A. Preparation of disulfhydryl ionic liquid

[0034] 0.100mol 1-methyl-2-mercaptoimidazole and 0.120mol 4-bromobutanethiol were dissolved in 20ml ethanol, protected by nitrogen, and stirred for 48 hours at 60 degrees Celsius. The solvent was evaporated to dryness, and acetone was recrystallized twice to obtain Imidazolyl bromide ionic liquid with two mercapto groups; 0.050mol imidazolyl bromide ionic liquid and 0.060mol NH 4 PF 6 The aqueous solution is mixed, stirred at room temperature for 24 hours, and the precipitate is dried and recrystallized twice with acetone to obtain a high-temperature resistant imidazole-based hexafluorophosphate ionic liquid.

[0035] B. Surface pretreatment of stainless steel wire

[0036] First, polish the surface of one end of the s...

Embodiment 3

[0039] Example 3: Preparation of copper nanoparticle-imidazole-based ionic liquid composite extraction coating metal wire solid phase micro extraction fiber

[0040] It includes the following three steps: A, B, and C:

[0041] A. Preparation of disulfhydryl ionic liquid

[0042] 0.100mol of imidazole and 0.200mol of 4-bromobutanethiol were dissolved in 25ml of ethanol, protected by nitrogen, and stirred for 48 hours at 80 degrees Celsius. The solvent was evaporated and recrystallized twice with acetone to obtain imidazolyl bromide with two mercapto groups. Salt ionic liquid; 0.060mol imidazole bromide salt ionic liquid and 0.070mol (CF 3 SO 2 ) 2 The NLi aqueous solution was mixed, stirred at room temperature for 24 hours, and the precipitate was dried and recrystallized twice with acetone to obtain a high-temperature resistant imidazolyl hexafluorosulfonamide salt ionic liquid.

[0043] B. Surface pretreatment of stainless steel wire

[0044] First, polish the surface of one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com