A kind of preparation method of graphene-coated solid-phase microextraction fiber

A technology for extracting fibers and graphene, applied in chemical instruments and methods, material separation, instruments, etc., can solve the problems of easy falling off of graphene coating and short service life, and achieve improved convenience, improved fragility, and improved use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

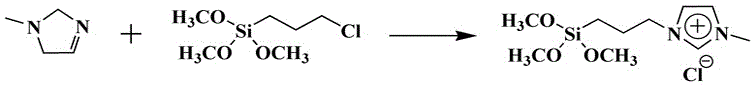

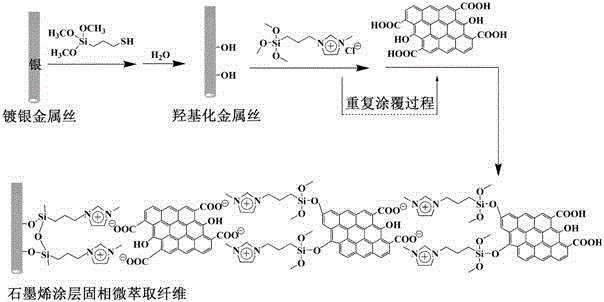

Method used

Image

Examples

Embodiment 1

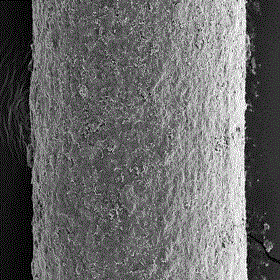

[0026] Embodiment 1: Preparation of graphene-coated stainless steel wire solid-phase microextraction fiber

[0027] Include the following steps A and B in turn:

[0028] A. Metal wire electroless silver plating

[0029] After 10 centimeters of long 0.15 millimeters thick stainless steel wire one end 3 centimeters are washed with water, methanol successively, put into electroless silver plating solution, the mass percent composition of glucose is 10%, and the mol ratio of silver ammonia ion and glucose is 1: 1. The silver plating reaction time is 2 hours at 20°C, and a layer of silver is deposited on the wire;

[0030] B. Preparation of Graphene Coating

[0031] Put the silver-plated end of the metal wire into a toluene solution of 20mmol / L 3-mercaptopropyltrimethoxysilane for 24 hours, self-assemble a layer of 3-mercaptopropyltrimethoxysilane molecules on the silver coating, and then place it in 0.1 Hydrolyze in mol / L dilute hydrochloric acid for 5 hours to hydroxylate the ...

Embodiment 2

[0032] Embodiment 2: Preparation of graphene-coated iron wire solid-phase microextraction fiber

[0033] Include the following steps A and B in turn:

[0034] A. Metal wire electroless silver plating

[0035] Wash one end 3 cm of a 15 cm long and 0.2 mm thick iron wire with water and methanol, and then put it into the electroless silver plating solution, the mass percentage of glucose is 15%, and the molar ratio of silver ammonia ion to glucose is 1:1.5 , the reaction time of silver plating at 25°C is 1.5 hours, and a layer of silver is deposited on the wire;

[0036] B. Preparation of Graphene Coating

[0037] Put the silver-plated end of the metal wire into a toluene solution of 10mmol / L 3-mercaptopropyltrimethoxysilane for 36 hours, self-assemble a layer of 3-mercaptopropyltrimethoxysilane molecules on the silver coating, and then place it in 0.5 Hydrolyze in mol / L dilute hydrochloric acid for 3 hours to hydroxylate the wire, take it out and dry it, put it in 20% ethanol...

Embodiment 3

[0038] Embodiment 3: Preparation of graphene-coated titanium wire solid-phase microextraction fiber

[0039] Include the following steps A and B in turn:

[0040] A. Metal wire electroless silver plating

[0041] 15 centimeters long 0.18 millimeters thick titanium wire one end 2 centimeters cleans up successively with water, methanol, puts into electroless silver plating solution, the mass percentage composition of glucose is 20%, and the mol ratio of silver ammonia ion and glucose is 1: 2. The reaction time of silver plating at 30°C is 1 hour, and a layer of silver is deposited on the wire;

[0042] B. Preparation of Graphene Coating

[0043] Put the silver-plated end of the metal wire into a toluene solution of 50mmol / L 3-mercaptopropyltrimethoxysilane for 8 hours, self-assemble a layer of 3-mercaptopropyltrimethoxysilane molecules on the silver coating, and then place Hydrolyze in 0.3mol / L dilute hydrochloric acid for 5 hours to hydroxylate the wire, take it out and dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com