Fire valve

A valve and fire-fighting technology, applied in valve details, valve device, valve shell structure and other directions, can solve the problems of insufficient flow, different flow of cross-pipe diversion and docking, overflow and return water pressure at the corner end of tri-pronged pipeline, etc., to improve diversion efficiency and improve efficiency. Continuous supply of pressure impulse, ensuring continuity and stability, and efficient effect of projectile arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

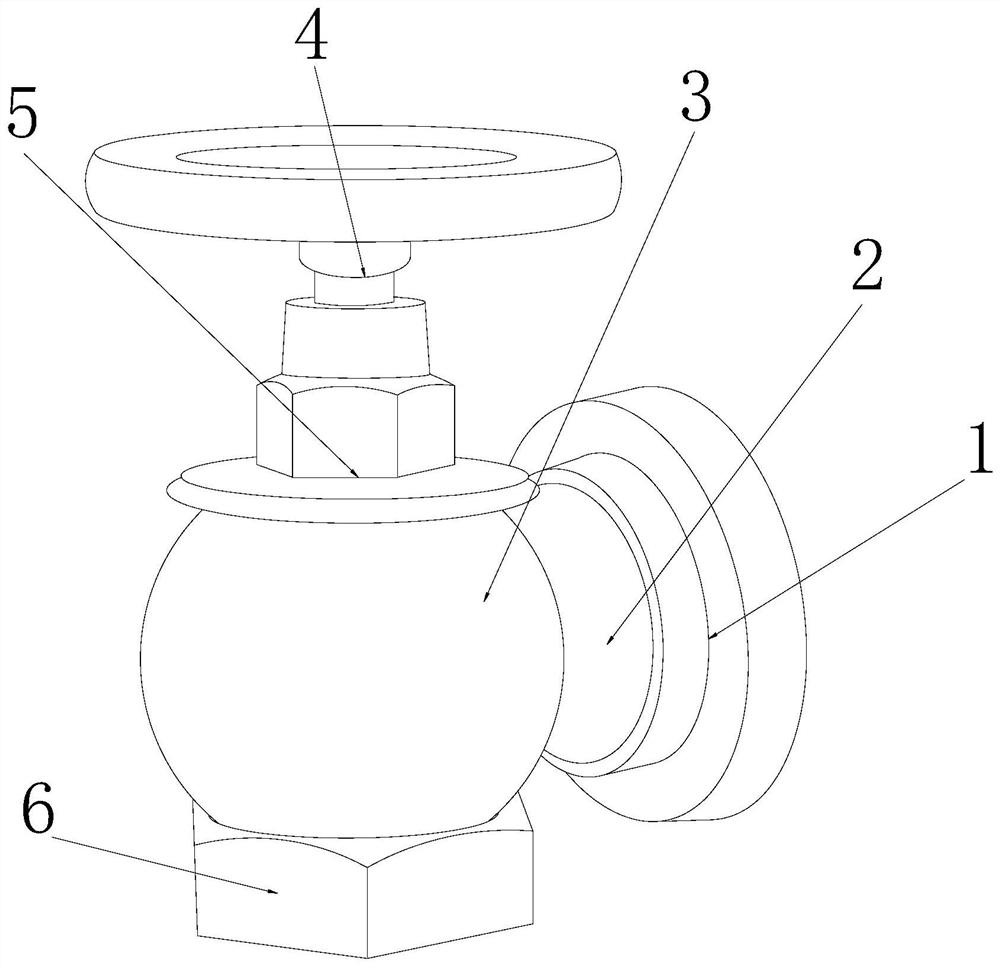

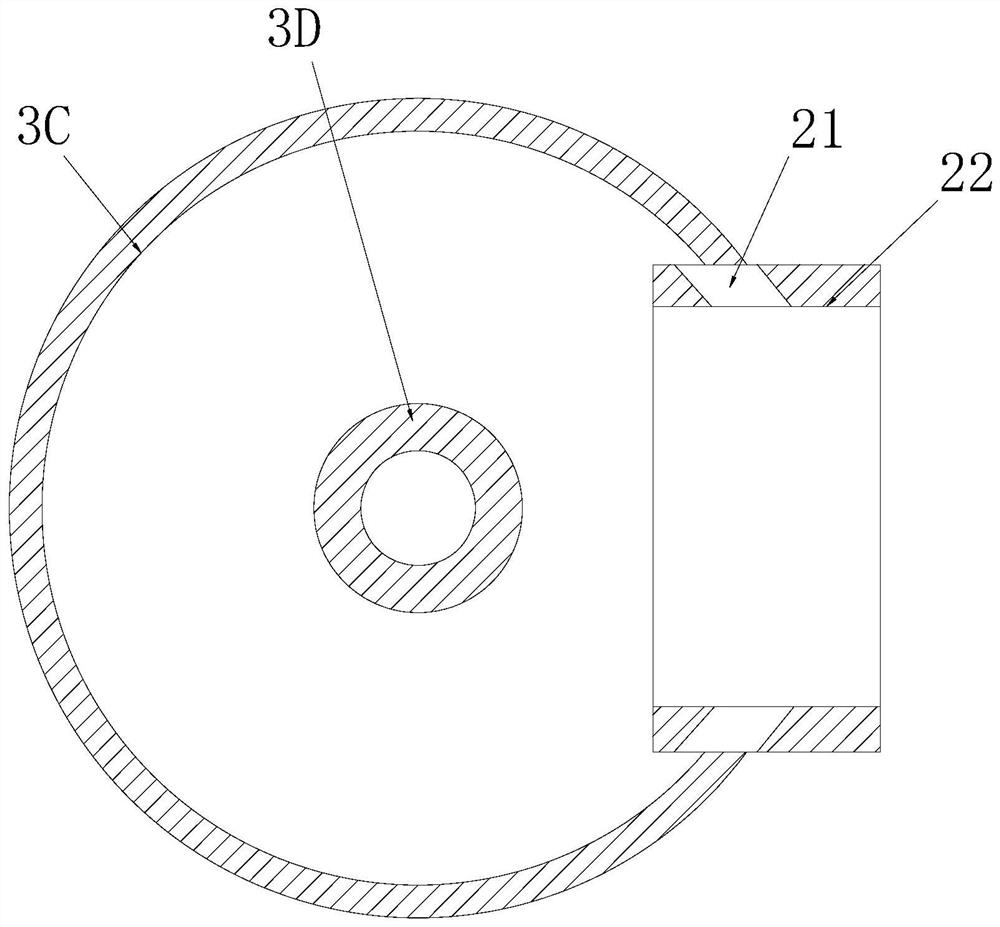

[0035] see Figure 1-Figure 8 , the present invention provides a fire valve, the structure of which includes: hoop sleeve plate seat 1, drain pipe end groove 2, star shot propeller ball valve 3, handle wheel frame 4, pressure flow support 5, nut base block 6 , the star-shooting propeller ball valve 3 is nested under the bottom of the pressure flow support 5 and the axes are collinear, the hoop sleeve disc seat 1 is fastened together with the drain pipe end groove 2 and communicates with each other, the The end groove 2 of the drain pipe is inserted on the right side of the star-shooting propeller ball valve 3 and the axes are co-linear, the handle frame 4 is inserted on the top of the pressure flow support 5, and the nut base block 6 Set under the bottom of the star-shooting propeller ball valve 3 and the axes are collinear. The star-shooting propeller ball valve 3 is provided with a shock-absorbing support rod 3A, a star-shooting nozzle frame 3B, an outer ball valve housing 3...

Embodiment 2

[0043] see Figure 1-Figure 8 , the present invention provides a kind of fire valve, other respects are identical with embodiment 1, and difference is:

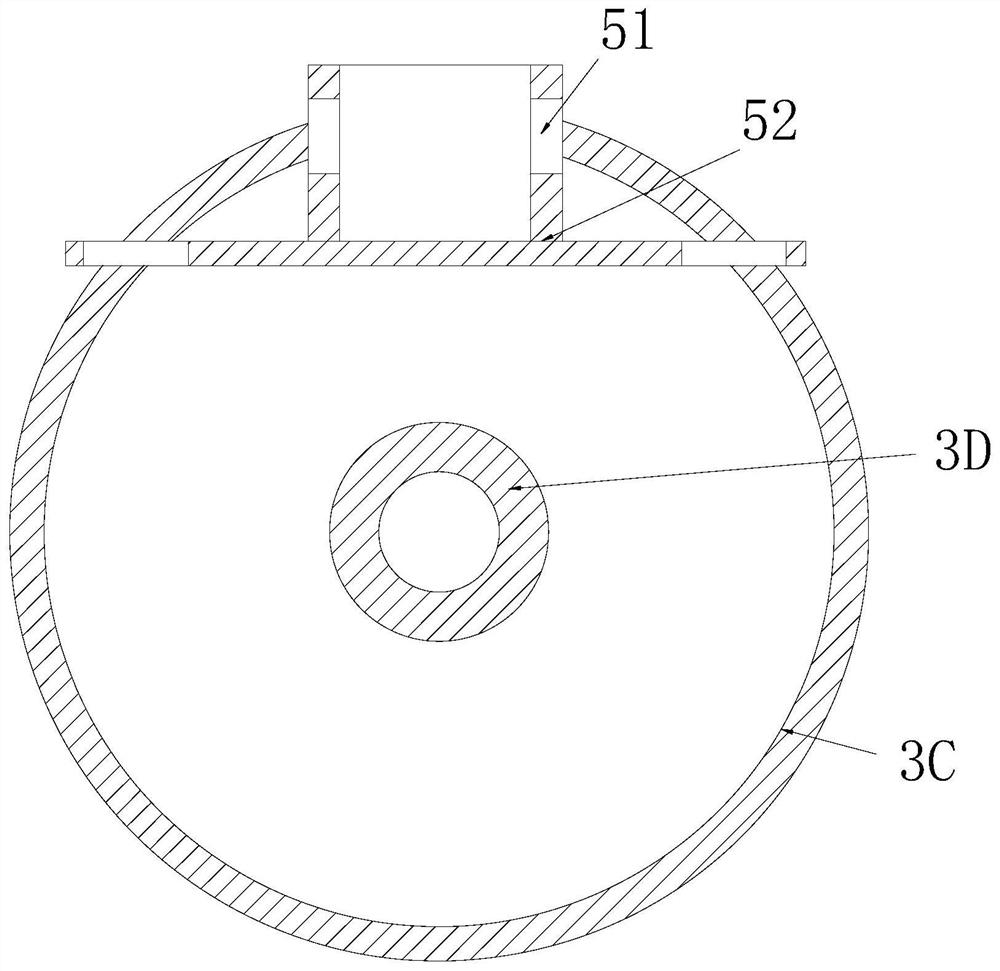

[0044] see image 3 , the pressure flow support 5 is made up of a bead groove plate 51 and a plate pressure cylinder seat 52, the bead groove plate 51 is installed inside the plate pressure cylinder seat 52, and the bead groove plate 51 and the plate pressure cylinder seat 52 adopt Interference fit, through the bead groove plate 51 in the plate pressure cylinder seat 52 to fit the ball valve housing horizontally and vertically to carry out press fitting and fastening, so as to improve the overall locking density.

[0045] see Image 6 The bead groove plate 51 is composed of a damping tube 511, a frame groove pad 512, and a flat plate groove 513. The damping tube 511 is embedded in the frame groove pad 512 and is on the same vertical plane. The frame groove pad 512 is provided with two and respectively nested in the left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com