Ionic liquid-molecular solvent composite extraction agent and application thereof

A technology of composite extractant and ionic liquid, which is applied in liquid solution solvent extraction, solvent extraction, extraction water/sewage treatment, etc., can solve the problems of reducing extraction efficiency, environmental pollution, and increasing the solubility of extractant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

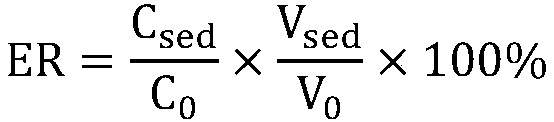

Method used

Image

Examples

Embodiment 1

[0033] Select 1-methyl-3-octylimidazole bis(trifluoromethylsulfonyl)imide salt as the ionic liquid, and butyl propionate as the molecular solvent to form a composite extractant for extracting phoxim in water, adding the composite extractant 10mL (wherein, the volume ratio of ionic liquid and molecular solvent is 7:3) was fully mixed in the centrifuge tube, and the volume of water sample was added to be 8mL (phoxim concentration was 0.112mg / L), and then the centrifuge tube was sonicated for 15min ( Ultrasonic input power: 400W), ice bath for 25min (0°C), centrifuge for 16min, take 20μL of the lower organic phase and put it into the high performance liquid chromatography to analyze the content, the content of phoxim in the lower phase after extraction is 15.5244mg / L , The recovery rate of phoxim calculated in the lower phase after extraction was 70%. At this time, the concentration of phoxim in the upper aqueous phase was 0.0777mg / L, and the national discharge standard was 3mg / L...

Embodiment 2

[0041] Select 1-octyl-3-methylimidazolium hexafluorophosphate as the ionic liquid, and butyl acetate as the molecular solvent to form a composite extractant for extracting fenthion in water, add 10 mL of the composite extractant (wherein, the ionic liquid and the molecular solvent The volume ratio is 7:3), after fully mixing in the centrifuge tube, add a water sample volume of 8mL (fenthion concentration is 0.112mg / L), and then ultrasonicate the centrifuge tube for 15min (ultrasonic input power: 400W) , ice-bath for 25min (the temperature of the ice-bath is 0°C), centrifuge for 16min, take 20μL of the organic phase of the lower layer and put it into the high-performance liquid chromatograph to analyze the content. The content of fenthion in the lower phase after extraction is 17.2378mg / L. The rate of recovery of thion increased to 77% from 24% when no ionic liquid was added, and from 65% when no molecular solvent was added. At this time, the concentration of fenthion in the upp...

Embodiment 3

[0043] Select 1-hexyl-3-methylimidazolium hexafluorophosphate as the ionic liquid, and hexyl acetate is used as a molecular solvent to form a composite extractant for extracting phoxim in water, and add 10 mL of the composite extractant (wherein, the volume of the ionic liquid and the molecular solvent ratio of 7:3), after fully mixing in the centrifuge tube, add a water sample volume of 8mL (phoxim concentration is 0.112mg / L), and then ultrasonically treat the centrifuge tube for 15min (ultrasonic input power: 400W), Ice-bath for 25min (the temperature of the ice-bath is 0°C), centrifuge for 16min, take 20 μL of the lower organic phase and enter it into a high-performance liquid chromatograph to analyze the content. The recovery rate of phosphorus increased from 27% when no ionic liquid was added and 67% when no molecular solvent was added to 87%. At this time, the concentration of phoxim in the upper aqueous phase was 0.0689mg / L, and the national discharge standard was 3mg / L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com