A supercritical co 2 Extracted Entrained Pharmaceutical Methods

A supercritical and extraction technology, applied in separation methods, solvent extraction, solid solvent extraction, etc., can solve the problems of entraining agent consumption, small extraction capacity, and reduced extraction rate, and achieve the effect that is conducive to deformation and shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

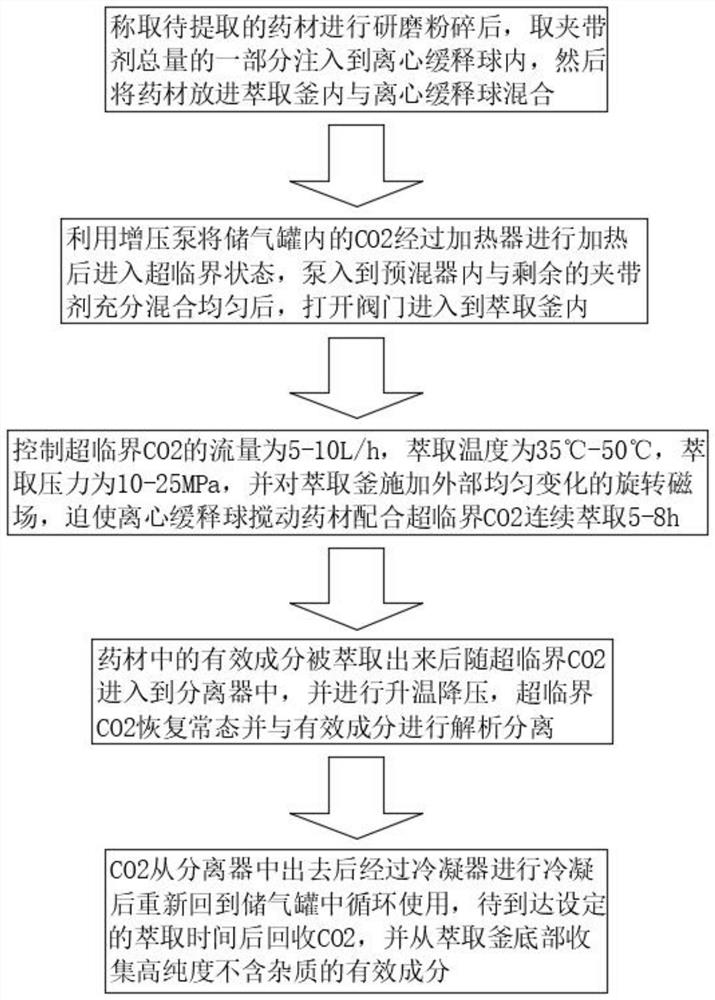

[0049] see figure 1 , a supercritical CO based 2 A method of extracting entrained pharmaceuticals comprising the steps of:

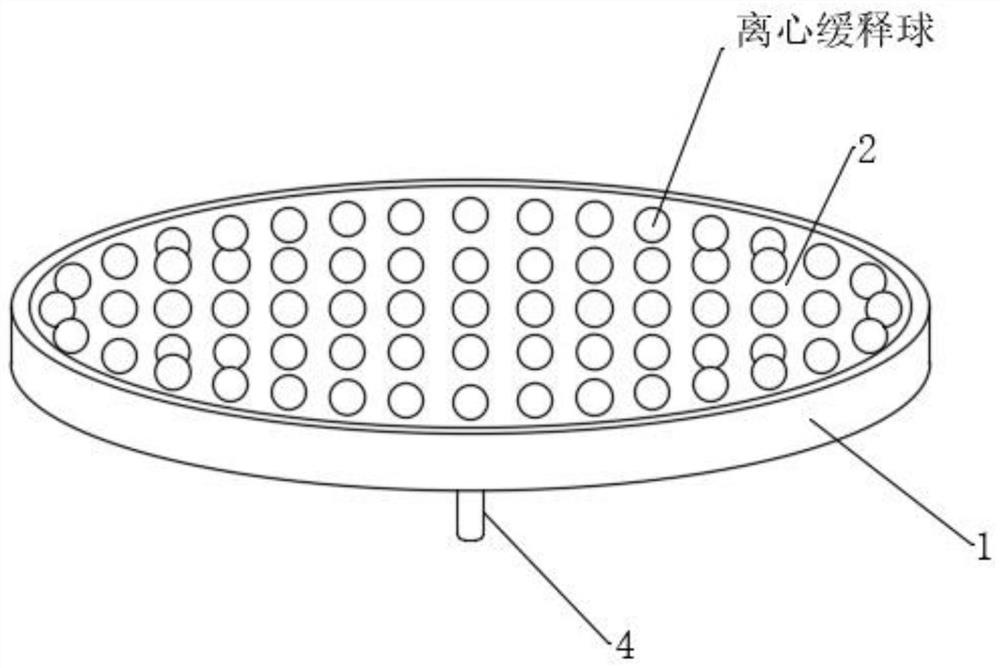

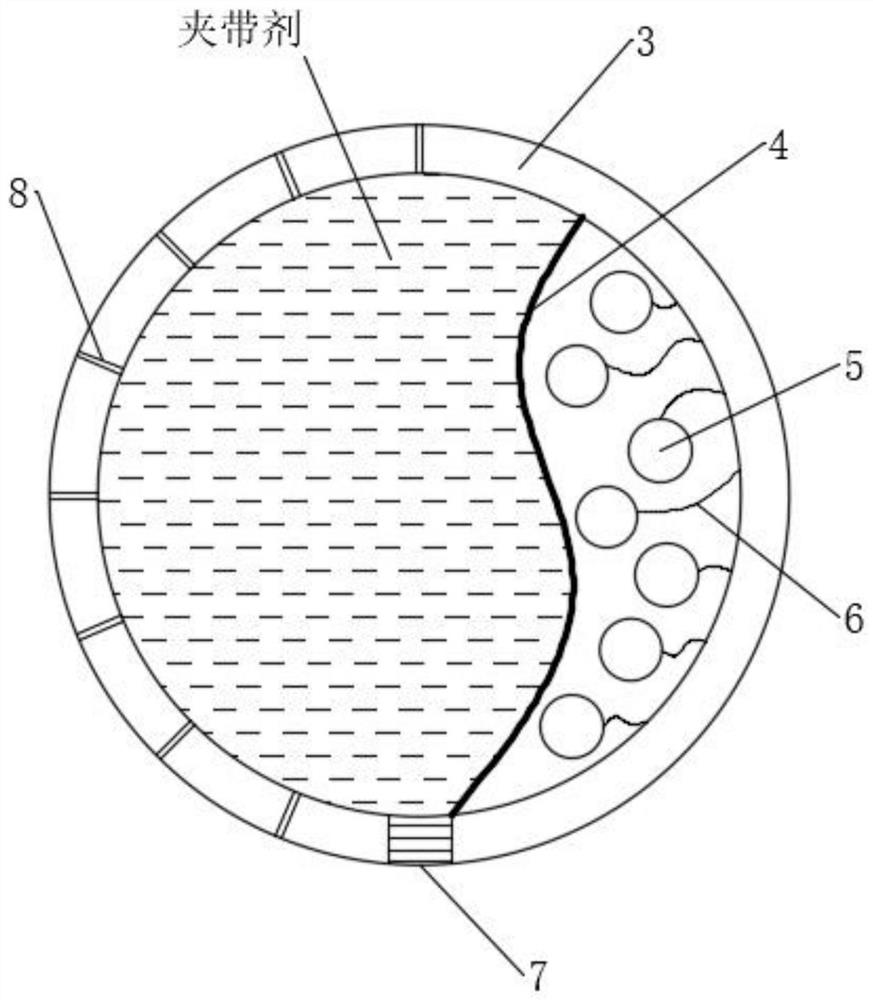

[0050] S1. After weighing the medicinal material to be extracted, grinding and pulverizing, take a part of the total amount of entraining agent and inject it into the centrifugal slow-release ball, and then put the medicinal material into the extraction kettle and mix it with the centrifugal slow-release ball;

[0051] S2, use the booster pump to remove the CO in the gas storage tank 2 After being heated by the heater, it enters the supercritical state, pumps it into the premixer and mixes it well with the remaining entrainer, then opens the valve and enters the extraction kettle;

[0052] S3, control supercritical CO 2 The flow rate is 5-10L / h, the extraction temperature is 35°C-50°C, the extraction pressure is 10-25MPa, and an external uniformly changing rotating magnetic field is applied to the extraction kettle to force the centrifugal slow-releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com