Method for realizing rapid extraction of organic compounds

An organic compound and extraction technology, applied in chemical instruments and methods, countercurrent extraction, solvent extraction, etc., can solve the problems of inability to carry out continuous extraction, large amount of extraction agent, and reduced extraction efficiency, and achieve mass transfer capacity and phase. Separation ability, accelerated separation, effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

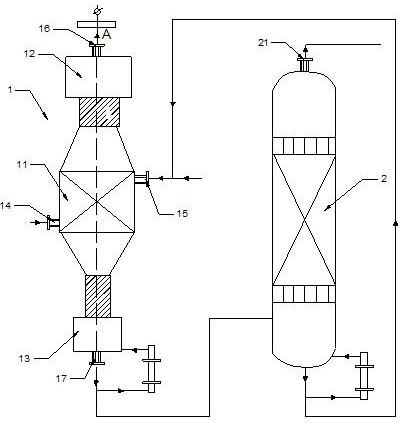

[0039] to combine figure 1 and figure 2 , a fast extraction device for realizing organic compounds, comprising an extraction tower 1 and a recovery tower 2, the extraction tower 1 includes an extraction cylinder 11, a light component cylinder 12 arranged at the upper end of the extraction cylinder 11 and a light component cylinder located at the bottom of the extraction cylinder 11 Heavy component drum 13, material inlet one 14 and extraction agent inlet two 15 are set on the said extracting drum 11, light component outlet one 16 is set at the top of said light component drum 12, and the bottom of said heavy component drum 13 is provided with outlet Two 17, the top of the recovery tower 2 is provided with a heavy component outlet three 21, the input end of the inlet one 14 is connected with a sample pump 8, and the input end of the inlet two 15 is connected with a solvent pump 9.

[0040] The extraction tower 1 is connected to the recovery tower 2 through the output end at t...

Embodiment 2

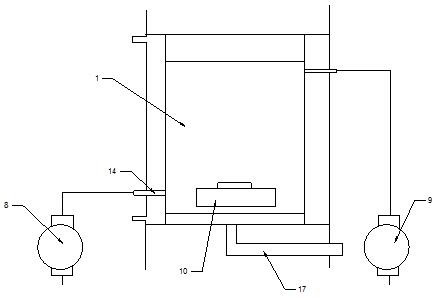

[0045] On the basis of Example 1, combined with figure 2 , the extraction cylinder 11 is provided with a stirring magnet 10, the outside of the stirring magnet 10 is coated with polytetrafluoroethylene, which has no specific adsorption to various solutions and prevents pollution. The stirring magnet is connected with a device The driving mechanism outside the extraction cylinder, the driving mechanism includes a stepping motor, a gear set connected to the output end of the stepping motor and a magnetic strip assembly connected to the gear set, and the magnetic strip assembly includes a magnetic strip corresponding to the stirring magnet and Holder for securing the magnetic strip.

[0046] Two magnets separated by a certain distance are used, and the coupling force of the magnets is used to transmit power from one magnet to the other, forming a non-contact transmission mechanism. When working, the motor drives the external magnetic strip assembly, and the coupling drive is enc...

Embodiment 3

[0049] A method for realizing rapid extraction of organic compounds, comprising the steps of:

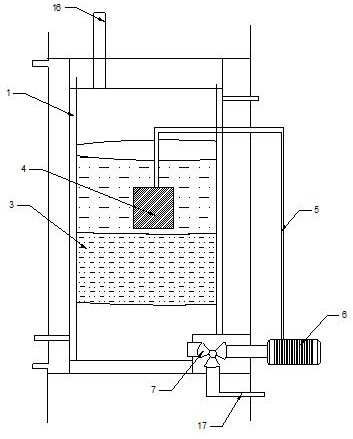

[0050] S1, the extractant enters the separation tank 3 from the inlet 15 at the upper end of the extraction cylinder 11, and the raw material liquid enters the separation tank 3 from near the inlet 14 at the bottom of the extraction cylinder 11;

[0051] S2, the extractant solution is in countercurrent contact with the rising raw material liquid gas phase, the light component in the raw material liquid is separated by the top outlet 16 of the light component cylinder 12, and the heavy component and extractant mixture in the raw material liquid are separated by the outlet of the heavy component cylinder 13 Bottom outlet two 17 enter recovery tower 2 and separate;

[0052] S3. The heavy components in the mixture are taken out from the outlet 3 at the top of the recovery tower 2, and the extractant circulates from the bottom of the recovery tower 2 into the inlet 2 15 of the extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com