Method for recycling rare earth in cerium-doped lutetium yttrium oyorthosilicate waste material

A yttrium lutetium silicate and cerium doping technology is applied in the field of comprehensive resource recovery and utilization, and can solve the problems of cumbersome operation, large water consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The cerium-doped yttrium lutetium silicate waste obtained by grinding and sieving was mixed with NaOH at a mass ratio of 1:1, subjected to alkali fusion at 600°C for 4 hours, washed with water until neutral, and then filtered to obtain the enriched material, of which The particle size of cerium-doped yttrium-lutetium silicate waste is 200 mesh;

[0053] Mix the enriched material and the hydrochloric acid solution with a concentration of 2.5mol / L according to the solid-to-liquid ratio of 7g:1mL, stir the acid solution at 50°C for 0.5h, filter out the impurities insoluble in the acid, and obtain the pickling solution ;

[0054] Using inductively coupled plasma-mass spectrometry to detect the content of rare earth ions and other impurity ions in the acid leaching solution, the leaching rate of rare earth ions in the obtained acid leaching solution is 95.86%. Among them, the working parameters of inductively coupled plasma-mass spectrometry : The carrier liquid flow rate i...

Embodiment 2~12

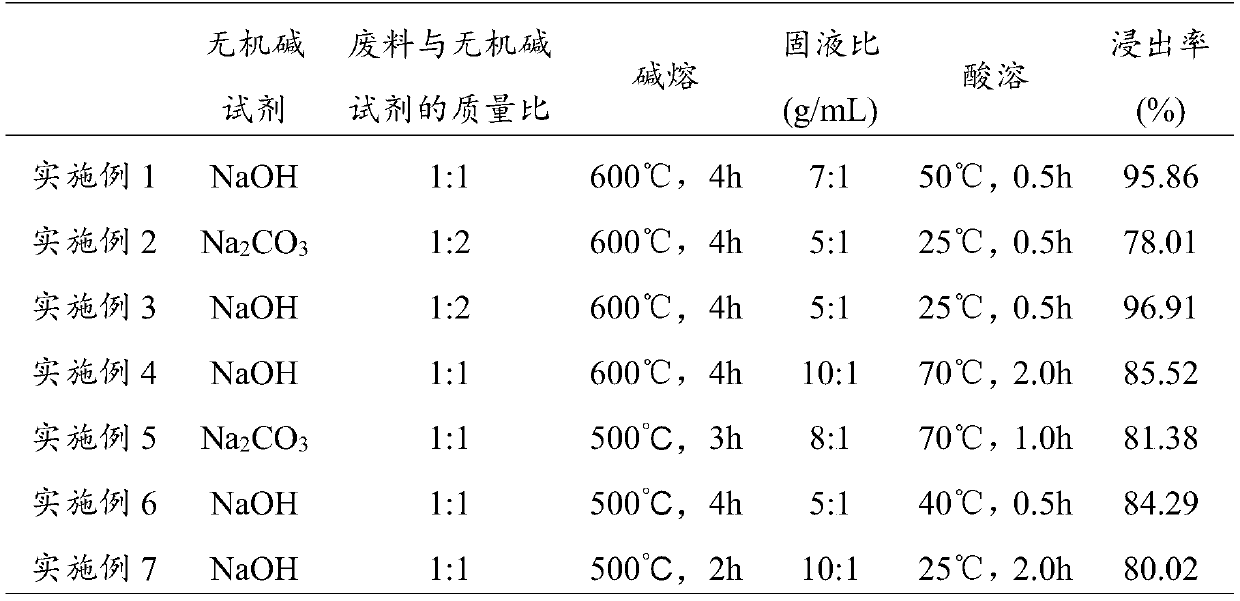

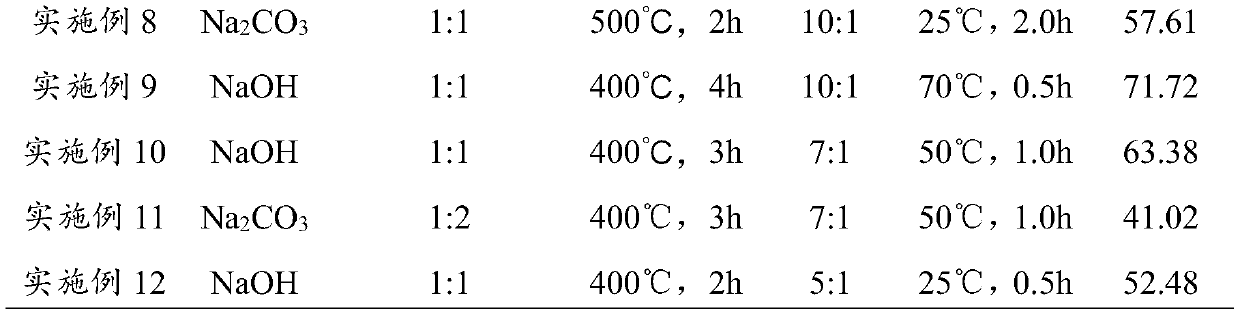

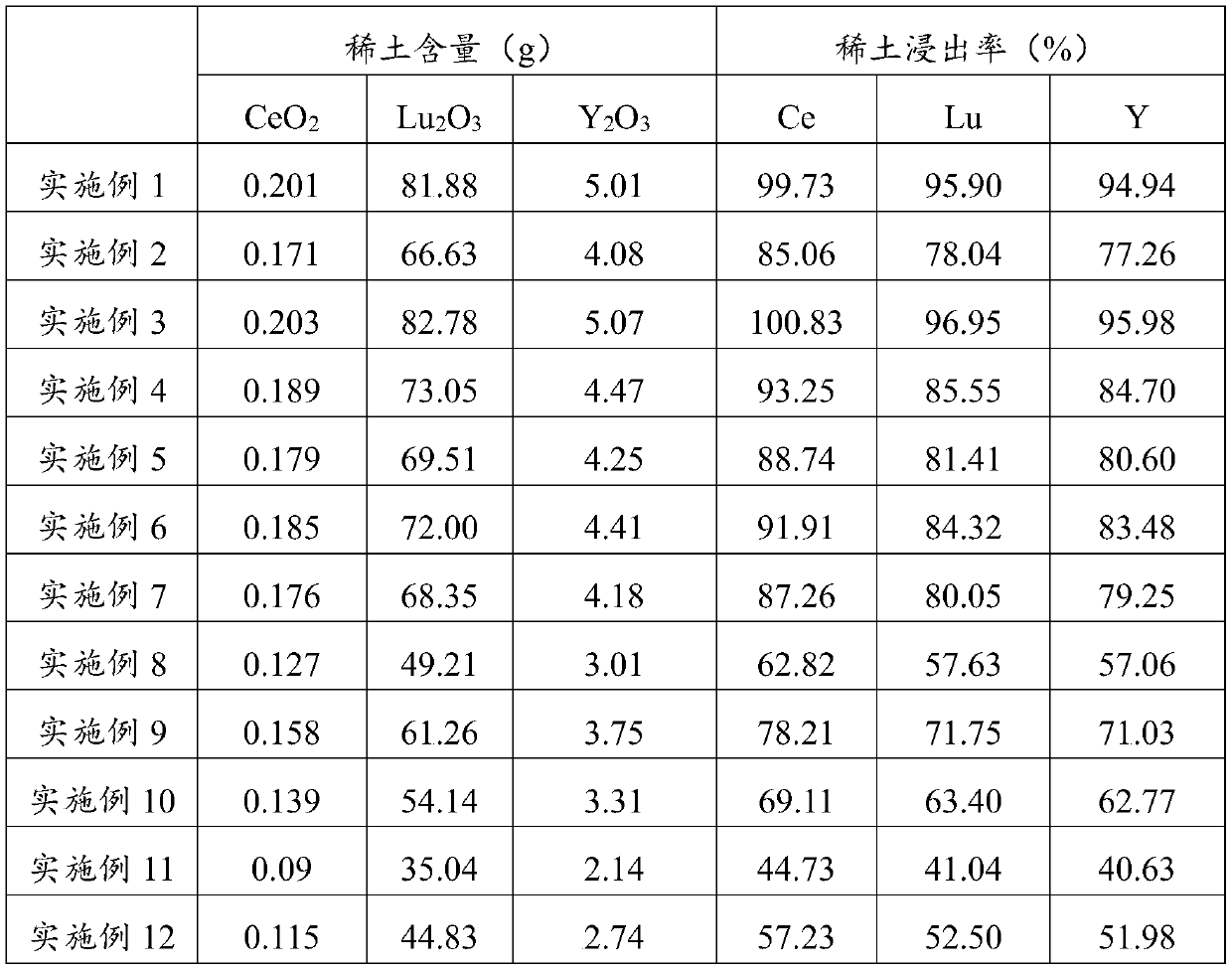

[0059] Reclaim cerium-doped yttrium lutetium silicate waste material according to the method of embodiment 1, the leaching rate of rare earth metal example in the experimental condition of embodiment 1~12 and the pickling solution of measurement is as shown in table 1, the other of embodiment 1~12 The experimental conditions are the same as in Example 1.

[0060] Experimental conditions and leaching rate of table 1 embodiment 1~12

[0061]

[0062]

[0063] It can be seen from Table 1 that the alkali melting temperature has the greatest impact on the leaching rate of rare earths. This is because as the alkali melting temperature increases, the lattice of yttrium lutetium silicate is distorted, and the crystal structure begins to collapse and become unstable overall, resulting in replacement of rare earth ions and OH in the environment - and CO 2 Rare earth oxides are formed, which are more easily leached by dilute acids.

Embodiment 13

[0070] Recycling cerium-doped yttrium-lutetium silicate waste according to the method in Example 1, the difference from Example 1 is that the ether amide functional ionic liquid is two (2-ethylhexyl)-3-oxo with hexafluorophosphate as an anion Glutaramide functional ionic liquid, the recovery rate of the finally obtained rare earth is 79.18%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com