Process for preparing high-purity zirconium oxychloride

A technology of high-purity zirconium oxychloride and crude zirconium oxychloride, which is applied in inorganic chemistry, zirconium compounds, chemical instruments and methods, etc. Volatile and water-soluble, the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

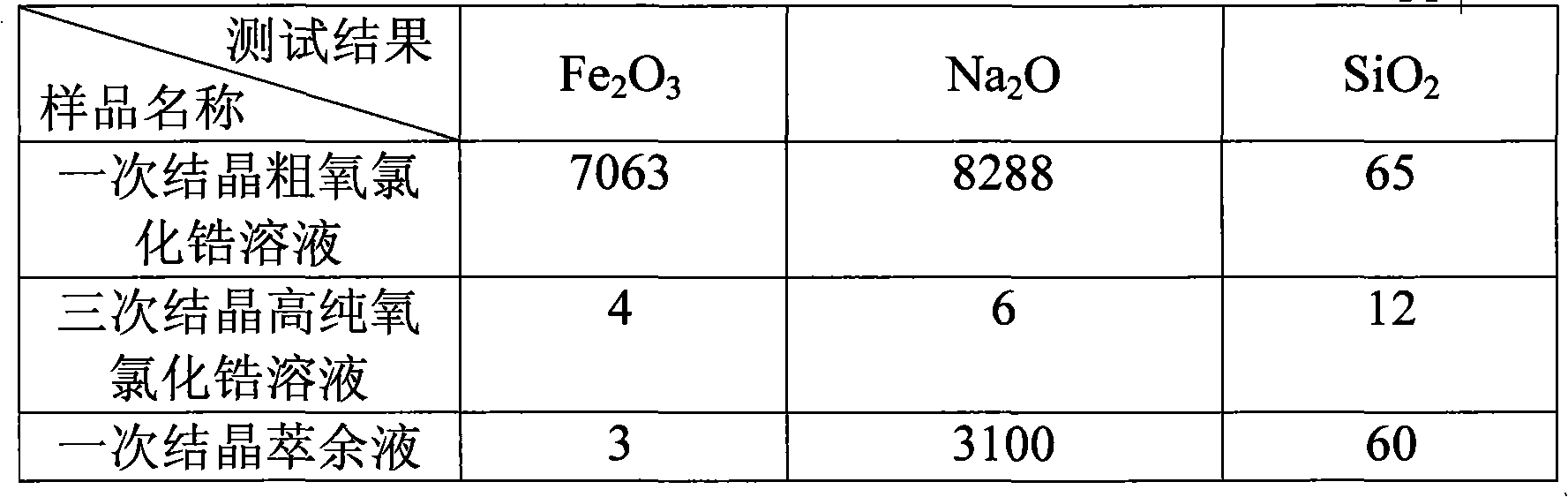

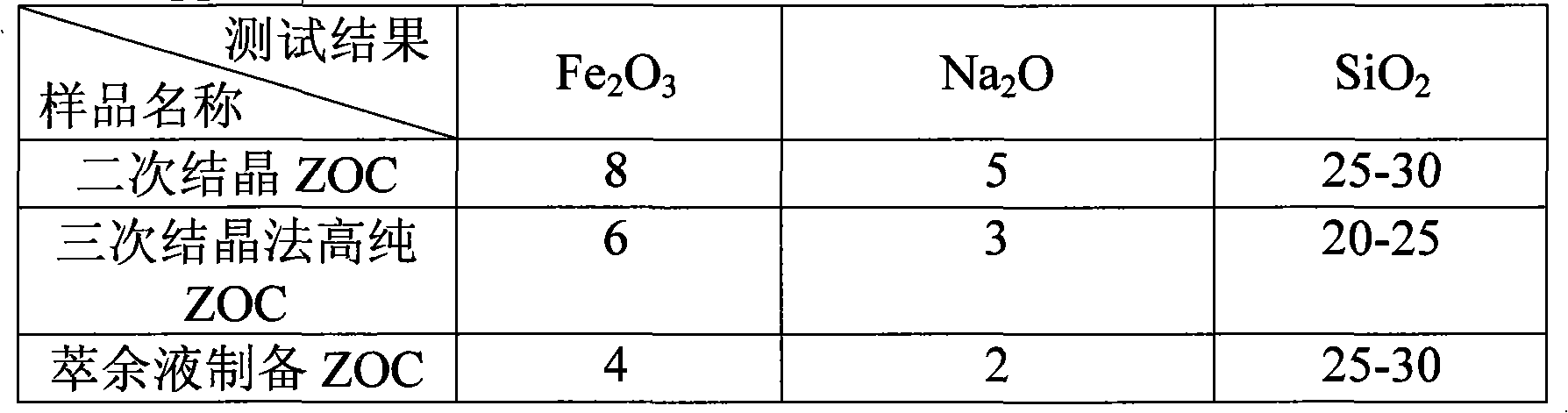

[0023] In the first step, pump 800 liters of industrial hydrochloric acid (Fe2O3≤10ppm) 10.5N into the high-level tank of industrial acid, and pump 5000 liters of pure water (conductivity≤20us / m) into the high-level tank, which is produced during the production of industrial zirconium oxychloride. The crude zirconium oxychloride solution is pumped into the high-level tank, and the acidity, zirconium content and impurity indicators are tested. The acidity of the crude zirconium oxychloride solution is required to be 4.5N, and the zirconium content is required to be 105g / L, and 1600L is pumped into the extraction tank of the extraction section. For crude zirconium oxychloride solution, pump 800L of pure water into the organic regeneration section; in the second step, mix 3500 liters of extraction agent N503 with 4500 liters of sulfonated kerosene and put them into the extraction tank. The third step is to turn on the stirring, turn on the flow meter at the same time, adjust the f...

Embodiment 2

[0025] In the first step, pump 800 liters of industrial hydrochloric acid (Fe2O3≤10ppm) 10N into the high-level tank of industrial acid, and pump 5000 liters of pure water (conductivity≤20us / m) into the high-level tank. The industrial zirconium oxychloride produced in the production process The crude zirconium oxychloride solution is pumped into the high-level barrel, and the acidity, zirconium content and impurity indicators are tested. The acidity of the crude zirconium oxychloride solution is required to be 4.6N, and the zirconium content is required to be 100g / L, and 1500L crude oil is pumped into the extraction tank of the extraction section. For the zirconium oxychloride solution, 700L of pure water is pumped into the organic regeneration section; in the second step, 3300 liters of extraction agent N503 and 4700 liters of sulfonated kerosene are mixed and put into the extraction tank. The third step is to turn on the stirring, and at the same time turn on the flow meter, ...

Embodiment 3

[0027]In the first step, pump 800 liters of industrial hydrochloric acid (Fe2O3≤10ppm) 11N into the high-level tank of industrial acid, and pump 5000 liters of pure water (conductivity≤20us / m) into the high-level tank. The industrial zirconium oxychloride produced in the production process The crude zirconium oxychloride solution is pumped into the high-level barrel, and the acidity, zirconium content and impurity indicators are tested. The acidity of the crude zirconium oxychloride solution is required to be 4.7N, and the zirconium content is required to be 110g / L, and 1400L crude oil is pumped into the extraction tank of the extraction section. For zirconium oxychloride solution, pump 800L of pure water into the organic regeneration section; in the second step, mix 3000 liters of extraction agent N503 with 5000 liters of sulfonated kerosene and put them into the extraction tank. The third step is to turn on the stirring, and turn on the flow meter at the same time, adjust the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com