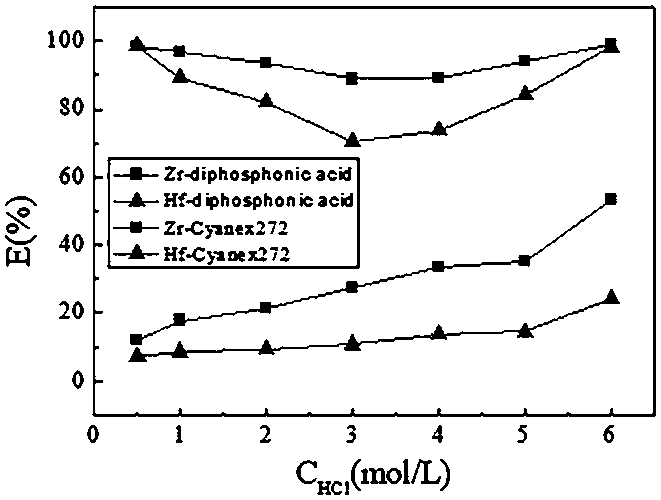

Diphosphoric acid extractant for extracting and separating zirconium and hafnium, and preparation method thereof

An extraction agent, bisphosphoric acid technology, applied in the field of new bisphosphoric acid extraction agent and its preparation, can solve the problem of low extraction rate of zirconium and hafnium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

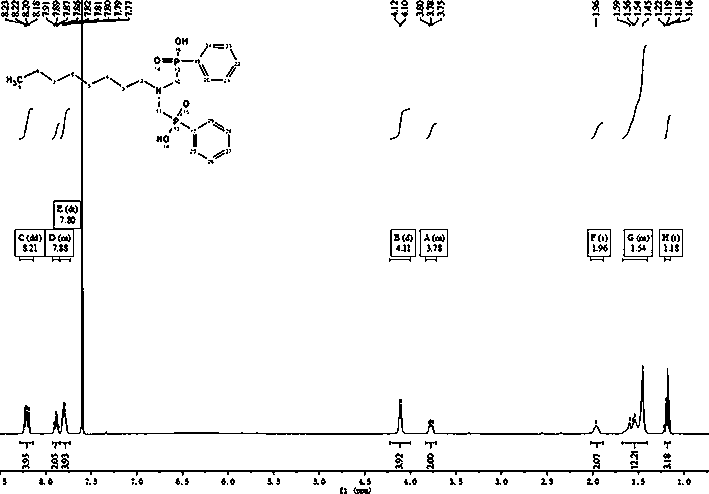

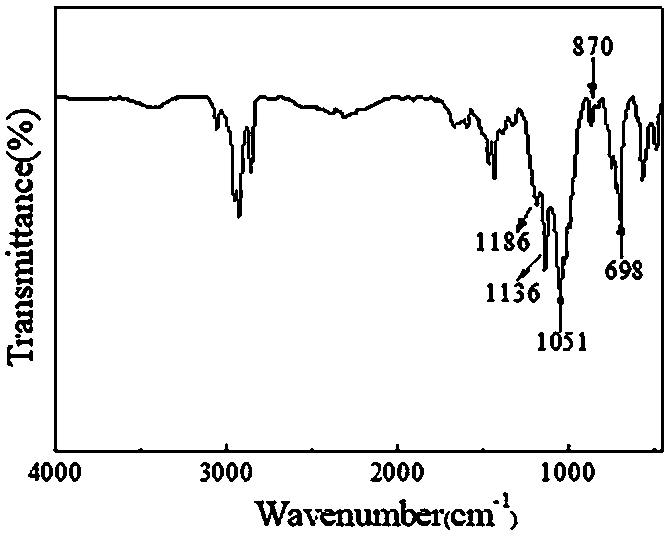

[0020] In a 100ml three-necked round-bottom flask equipped with a spherical condenser and a mechanical stirring device, add 0.02 mol n-octylamine, 0.02 mol phenyl hypophosphorous acid, 35 ml water and 5 ml concentrated hydrochloric acid, stir the mixture and heat it to 60°C, gradually changing to It is a colorless transparent solution. Add 6 ml of 37% formaldehyde solution dropwise at reflux temperature, keep the temperature constant, and react for one hour. After cooling, the organic phase was washed several times with dilute hydrochloric acid, and then further purified by column chromatography to finally obtain N,N-n-octylamine di(methylene phenylphosphinic acid). The extractant yield and purity are shown in Table 1.

Embodiment 2

[0022] In a 100ml three-necked round-bottom flask equipped with a spherical condenser and a mechanical stirring device, add 0.02 mol n-octylamine, 0.04 mol phenyl hypophosphorous acid, 25 ml water and 15 ml concentrated hydrochloric acid, stir the mixture and heat it to 60°C, gradually changing to It is a colorless transparent solution. Add 6 ml of 37% formaldehyde solution dropwise at reflux temperature, keep the temperature constant, and react for two hours. After cooling, the organic phase was washed several times with dilute hydrochloric acid, and then further purified by column chromatography to finally obtain N,N-n-octylamine di(methylene phenylphosphinic acid). The extractant yield and purity are shown in Table 1.

Embodiment 3

[0024] In a 100ml three-necked round-bottomed flask equipped with a spherical condenser and a mechanical stirring device, add 0.02 mol of n-octylamine, 0.06 mol of phenyl hypophosphorous acid, 10 ml of water and 30 ml of concentrated hydrochloric acid, stir and heat the mixture to 60°C, gradually becoming It is a colorless transparent solution. Add 6 ml of 37% formaldehyde solution dropwise at reflux temperature, keep the temperature constant, and react for four hours. After cooling, the organic phase was washed several times with dilute hydrochloric acid, and then further purified by column chromatography to finally obtain N,N-n-octylamine di(methylene phenylphosphinic acid). The extractant yield and purity are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com