Method for purifying and regenerating P204 and P507 extraction agents

An extraction agent and extraction technology, applied in the direction of improving process efficiency, etc., can solve problems affecting ecology, hazardous waste treatment and pollution of the environment, and achieve the effects of saving production costs, simple treatment process, and low regeneration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

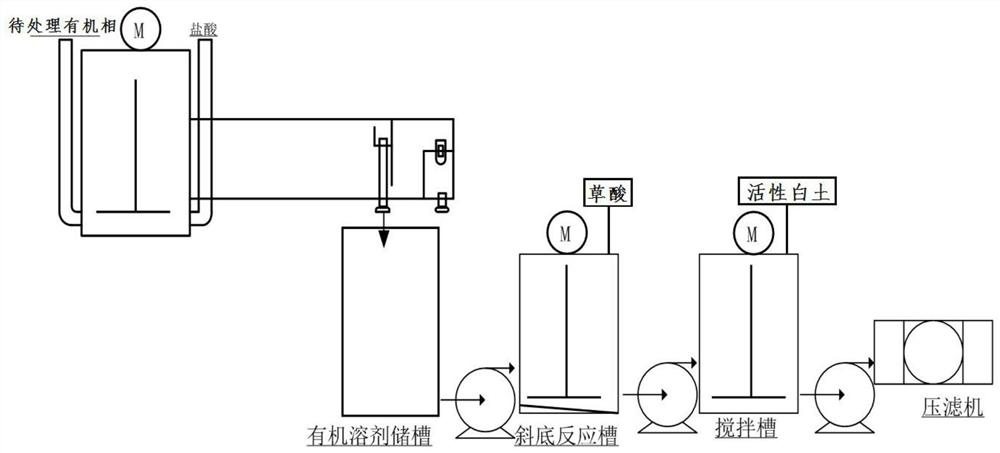

Image

Examples

Embodiment 1

[0029] On-site confirmation that the extraction line to be processed has been stopped, and all feed valves have been closed; the stirring of the production line is normally turned on, the inlet of the clarification section on the extraction tank on the extraction section and the water seal of the mixing chamber are opened, and the inlet of the pneumatic diaphragm pump is inserted into the organic phase; the diaphragm pump The outlet is placed in the first two stages of the washing section; the washing acid pump is turned on, and the flow rate is appropriately increased to ensure that the metals in the organic phase are completely stripped; the stripped organic phase is driven into the organic solvent storage tank; the stripped acid is new Prepared 6.0mol / L hydrochloric acid.

[0030] After extracting the extractant in the extraction section and the washing section in sequence, the washing acid pump is turned off; the organic phase to be treated on the production line has all go...

Embodiment 2

[0034] On-site confirmation that the extraction line to be processed has been shut down, and all feed valves have been closed.

[0035] The production line is stirred and opened normally, and the inlet of the clarification section on the extraction tank on the extraction section and the water seal of the mixing chamber are opened, and the inlet of the pneumatic diaphragm pump is inserted into the organic phase; the outlet of the diaphragm pump is placed in the first two stages of the washing section; Increase the flow rate to ensure that the metals in the organic phase are completely stripped; back-extraction acid, the normal flow of washing water is turned on; the organic phase of the extraction section is driven to the organic solvent storage tank step by step; the stripping acid is newly prepared 8.0mol / L of hydrochloric acid.

[0036] After the extractants in the extraction section and the washing section are exhausted in sequence, the washing acid pump is turned off. The...

Embodiment 3

[0041] On-site confirmation that the extraction line to be processed has been shut down, and all feed valves have been closed.

[0042] The production line is stirred and opened normally, and the inlet of the clarification section on the extraction tank on the extraction section and the water seal of the mixing chamber are opened, and the inlet of the pneumatic diaphragm pump is inserted into the organic phase; the outlet of the diaphragm pump is placed in the first two stages of the washing section; Increase the flow rate to ensure that the metals in the organic phase are completely stripped; back-extraction acid, the normal flow of washing water is turned on; the organic phase of the extraction section is driven to the organic solvent storage tank step by step; the stripping acid is newly prepared 7.0mol / L of hydrochloric acid.

[0043] After extracting the extractant in the extraction section and the washing section in sequence, the washing acid pump is turned off; and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com