Method for dephenolization of phenolic wastewater through multi-stage mixed intensified separation

A technology for strengthening separation and phenol wastewater, applied in separation methods, chemical instruments and methods, solvent extraction, etc., can solve the problems of increasing energy consumption of extracting agent by stripping and recovering, large amount of extraction of raffinate phase, and difficult control of separation interface, etc. Achieve the effects of easy online analysis and automatic control, fast mass transfer balance, and avoidance of back-mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, extraction and dephenolization of coal chemical industry phenolic waste water

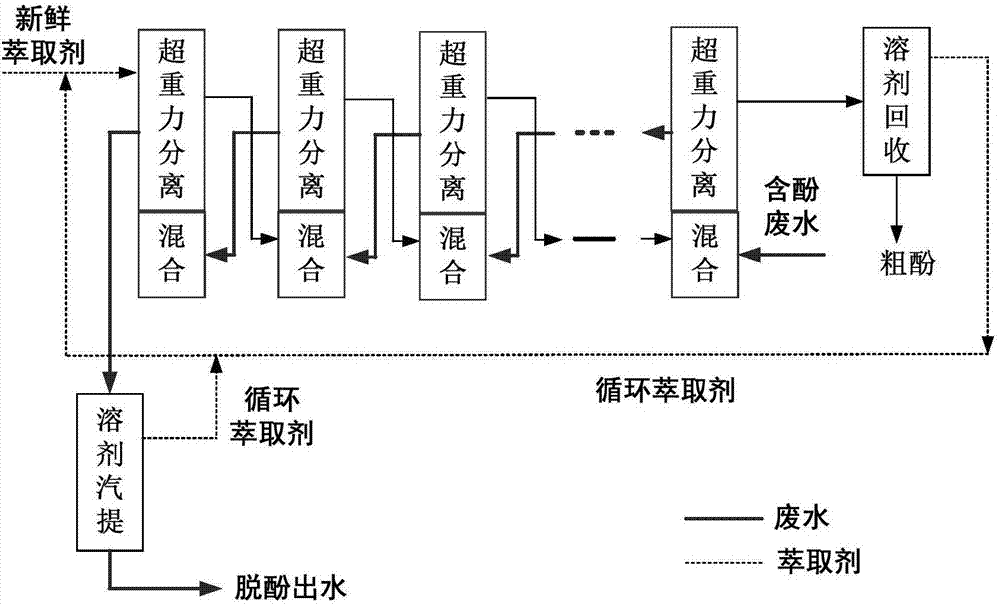

[0039] according to figure 2 The process flow chart shown in the process extracts and removes phenols from coal chemical industry wastewater containing phenols. The specific steps are as follows:

[0040](1) The extractant (methyl isobutyl ketone) with a volume ratio of 1:6 and phenol-containing wastewater (total phenol 5750mg / L, polyphenol 1820mg / L, COD content 19340mg / L, pH value 8.0) by reverse The direction is sent to a multi-stage extraction device connected in series with 5 high-gravity extractors for multi-stage countercurrent extraction (level 5), and the final extraction phase (containing crude phenol and extractant) and the final raffinate phase (wastewater containing a small amount of extractant) are collected. );

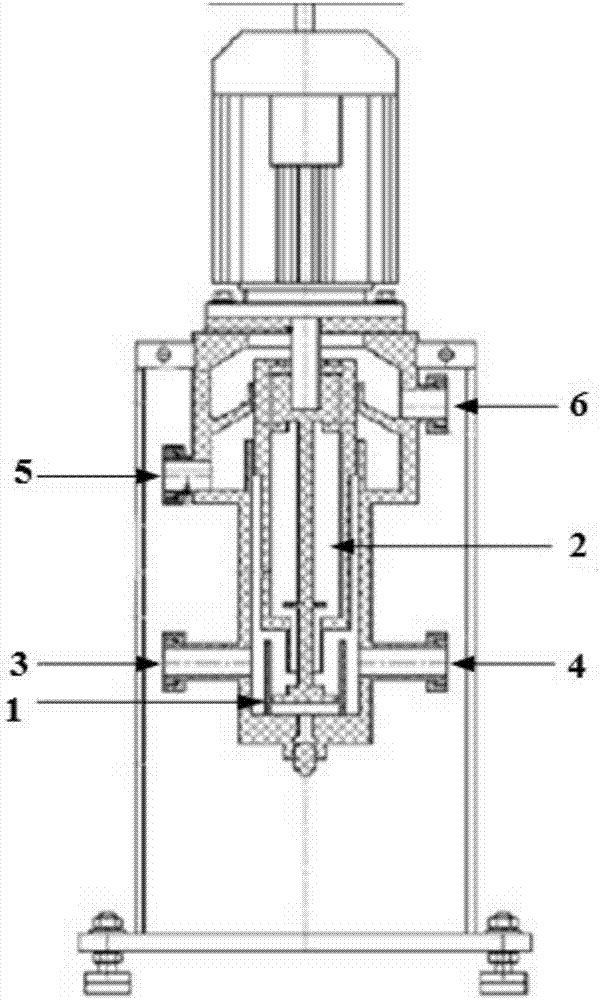

[0041] Every high-gravity extractor comprises a mixing chamber (1) and an enhanced separation chamber (2), and the extractant and the phenol-containin...

Embodiment 2

[0044] Embodiment 2, extraction and dephenolization of coal chemical industry phenolic wastewater

[0045] according to figure 2 The process flow chart shown in the process extracts and removes phenols from coal chemical industry wastewater containing phenols. The specific steps are as follows:

[0046] (1) The extractant (methyl isobutyl ketone) with a volume ratio of 1:4 and phenol-containing wastewater (total phenol 5750mg / L, polyphenol 1820mg / L, COD content 19340mg / L, pH value 8.0) by reverse The direction is sent to a multi-stage extraction device connected in series with 3 high-gravity extractors for multi-stage countercurrent extraction (3 stages), and the final extraction phase (containing crude phenol and extractant) and the final raffinate phase (wastewater containing a small amount of extractant) are collected. );

[0047] Every high-gravity extractor comprises a mixing chamber (1) and an enhanced separation chamber (2), and the extractant and the phenol-containi...

Embodiment 3

[0050] Example 3, Extraction and dephenolization of coal chemical industry phenolic wastewater

[0051] according to figure 2 The process flow chart shown in the process extracts and removes phenols from coal chemical industry wastewater containing phenols. The specific steps are as follows:

[0052] (1) The extractant (methyl isobutyl ketone) with a volume ratio of 1:8 and phenol-containing wastewater (total phenol 5750mg / L, polyphenol 1820mg / L, COD content 19340mg / L, pH value 7.0) by reverse The direction is sent to a multi-stage extraction device connected in series with 7 high-gravity extractors for multi-stage countercurrent extraction (7 stages), and the final extraction phase (containing crude phenol and extractant) and the final raffinate phase (wastewater containing a small amount of extractant) are collected. );

[0053] Every high-gravity extractor comprises a mixing chamber (1) and an enhanced separation chamber (2), and the extractant and the phenol-containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com