Compound extractant for deep purification of lithium ore leachate and purification process

A compound extraction agent and deep purification technology, which is applied in the field of metal smelting, can solve the problems of low impurity removal efficiency of lithium ore leachate, and achieve good phase separation effect, good extraction effect, and high lithium recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

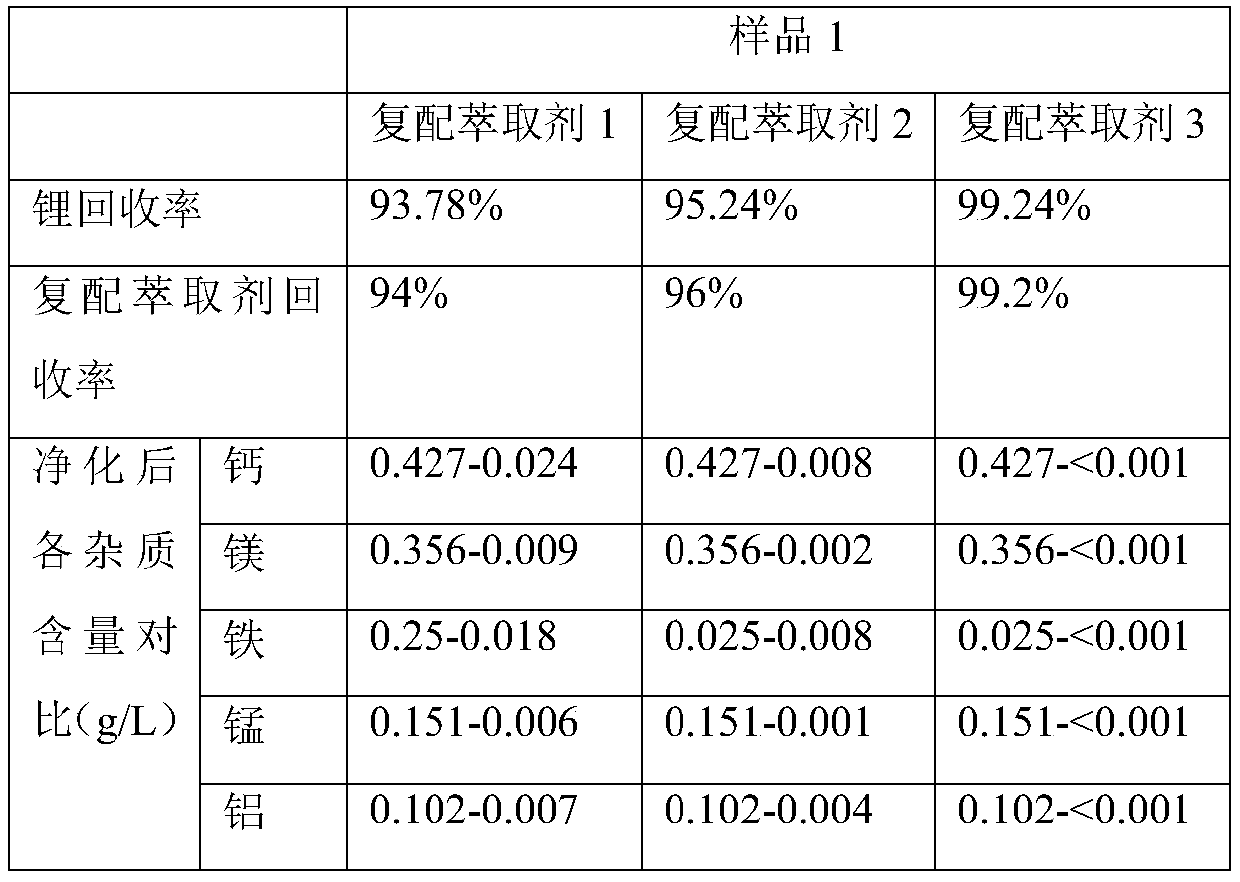

[0035] After testing, the impurity content in sample 1 is as follows:

[0036] Calcium: 0.427g / L, Magnesium: 0.356g / L, Iron: 0.25g / L, Manganese: 0.151g / L, Aluminum: 0.102g / L, Lithium: 9g / L, pH 5.5;

[0037] 1.1 Preparation of compound extractant:

[0038] Compound extractant 1: the volume fraction of AD290 is 10%, and the balance is kerosene;

[0039] Compound extractant 2: AD290 volume fraction is 10%, tertiary carbon carboxylic acid Versatic911 volume fraction is 15%, and the balance is kerosene;

[0040] Compound extractant 3: AD290 volume fraction is 10%, tertiary carbon carboxylic acid Versatic911 volume fraction is 15%, and the balance is white oil;

[0041] 1.2 Wash the compound extractants 1, 2, and 3 with lye:

[0042] Prepare a NaOH solution with a mass fraction of 10%, the volume ratio of the compound extractant to NaOH solution is 10:1, the number of washing stages is 3, and the compound extractant after alkali washing is separated after washing.

[0043] 1.3 P...

Embodiment 2

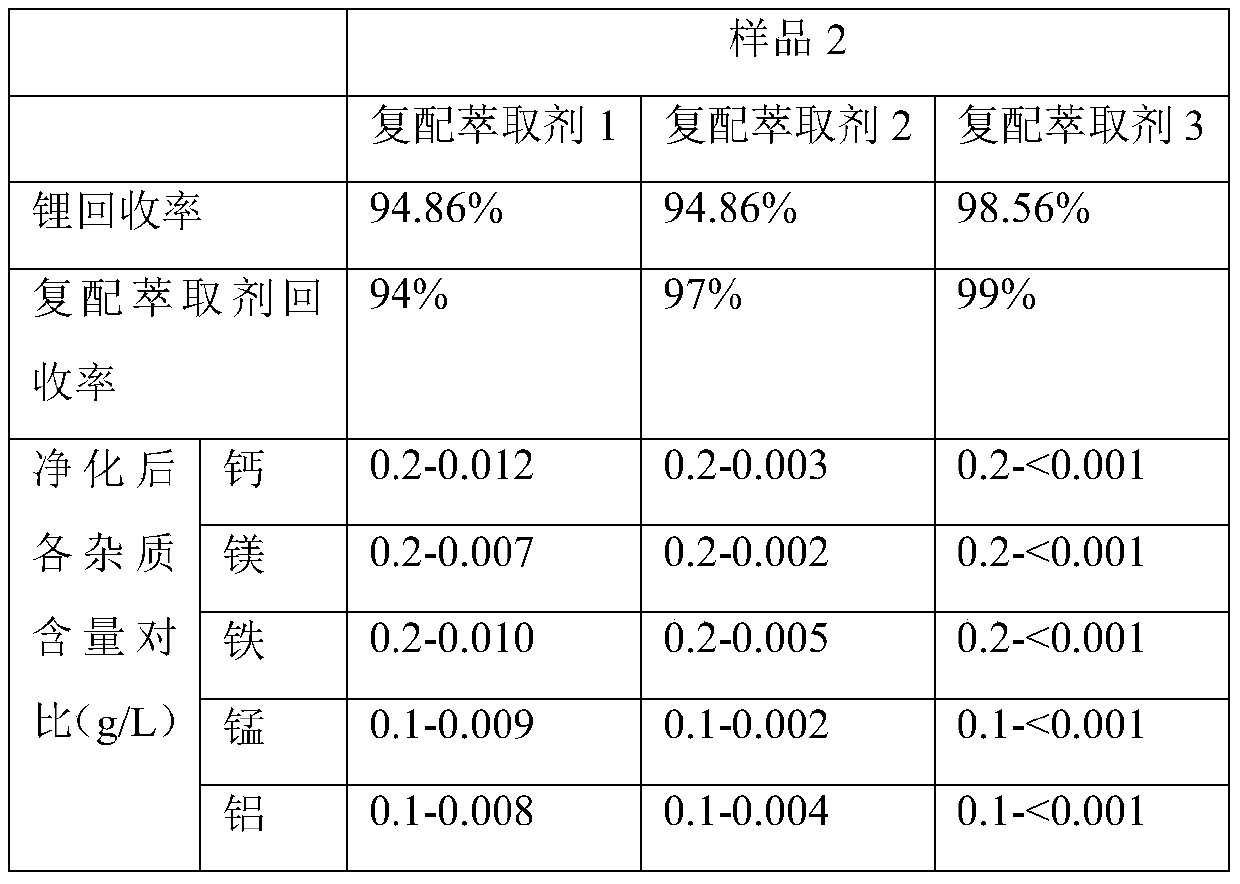

[0050] After testing, the impurity content in sample 2 is as follows:

[0051] Calcium: 0.2g / L, Magnesium: 0.2g / L, Iron: 0.2g / L, Manganese: 0.1g / L, Aluminum: 0.1g / L, Lithium: 10.3g / L, pH 6;

[0052] 2.1 Preparation of compound extractant:

[0053] Compound extractant 1: the volume fraction of AD290 is 5%, and the balance is sulfonated kerosene;

[0054] Compound extractant 2: the volume fraction of AD290 is 5%, the volume fraction of tertiary carbon carboxylic acid Versatic911 is 20%, and the balance is sulfonated kerosene;

[0055] Compound extractant 3: the volume fraction of AD290 is 5%, the volume fraction of tertiary carbon carboxylic acid Versatic911 is 20%, and the balance is white oil;

[0056] 2.2 Wash the compound extractants 1, 2, and 3 with lye:

[0057] Prepare a NaOH solution with a mass fraction of 15%, the volume ratio of the compound extractant to NaOH solution is 12:1, the number of washing stages is 2, and the compound extractant after alkali washing is s...

Embodiment 3

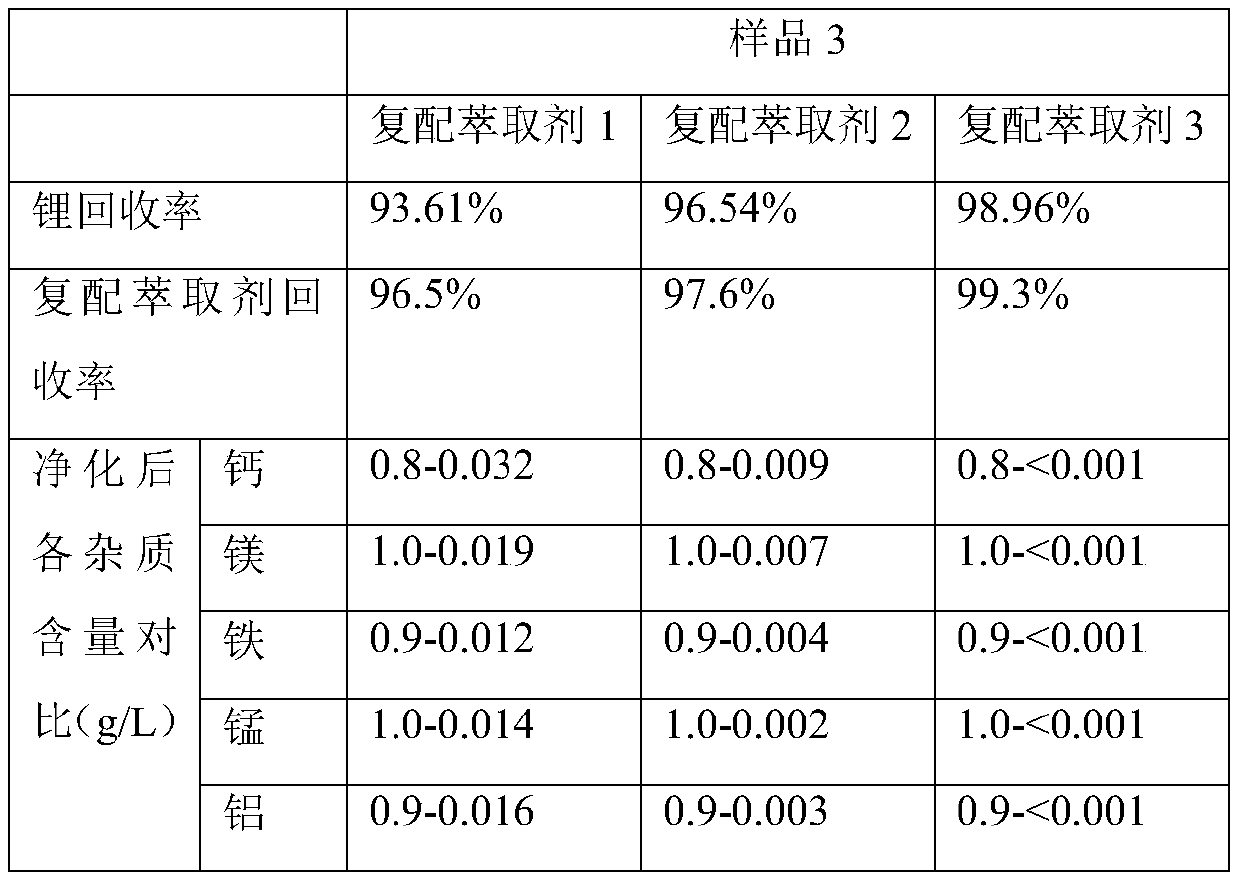

[0065] After testing, the impurity content in sample 3 is as follows:

[0066] Calcium: 0.8g / L, Magnesium: 1.0g / L, Iron: 0.9g / L, Manganese: 1.0g / L, Aluminum: 0.9g / L, Lithium: 11.6g / L, pH 6.5;

[0067] 3.1 Preparation of compound extractant:

[0068] Compound extractant 1: the volume fraction of AD290 is 15%, and the balance is sulfonated kerosene;

[0069] Compound extractant 2: the volume fraction of AD290 is 15%, the volume fraction of tertiary carbon carboxylic acid Versatic911 is 20%, and the balance is sulfonated kerosene;

[0070] Compound extractant 3: AD290 volume fraction is 15%, tertiary carbon carboxylic acid Versatic911 volume fraction is 20%, and the balance is white oil;

[0071] 3.2 Wash the compound extractants 1, 2, and 3 with lye:

[0072] Prepare a NaOH solution with a mass fraction of 20%, the volume ratio of the compound extractant to NaOH solution is 20:1, and the number of washing stages is 1, and the compound extractant after alkali washing is separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com