Modified PVA electrolyte membrane for flexible super capacitor, and preparation method and application thereof

A technology for supercapacitors and electrolyte films, which is applied in the manufacture of hybrid capacitor electrolytes and hybrid/electric double layer capacitors. It can solve problems that limit practical applications, low swelling, and affect the electrochemical performance of assembled capacitors, and achieve easy large-scale industrialization. The effect of low production and product cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In the aforementioned preparation method, the way of removing water can be either natural air drying or drying.

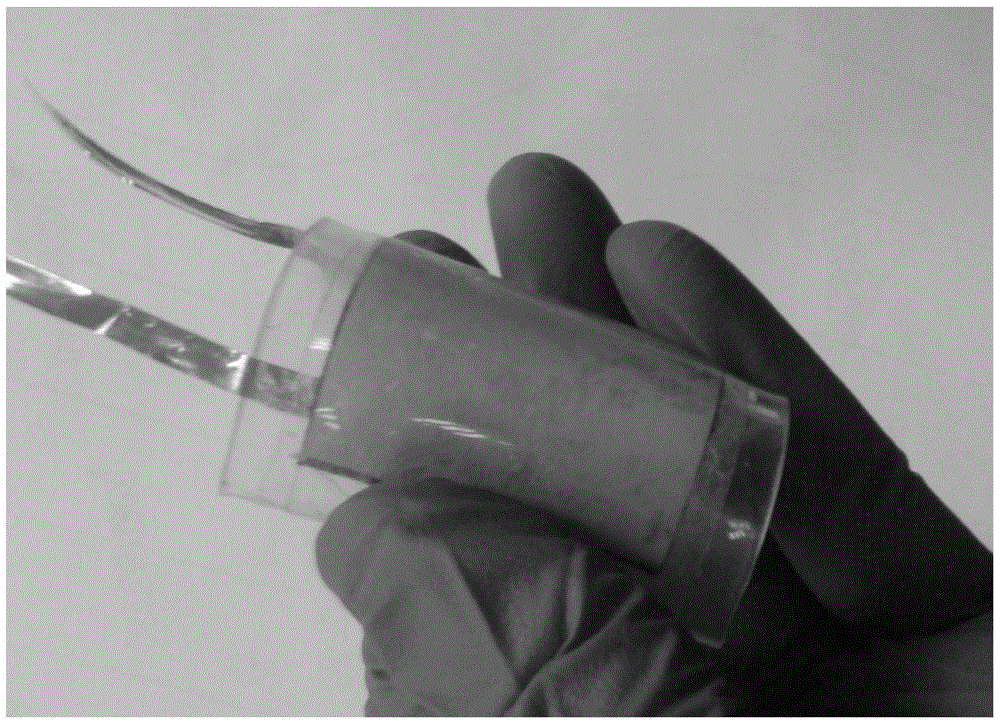

[0050] The foregoing electrode material may be a flexible substrate covering the electrode sheet of graphene material, but it is not limited to graphene, and may also be other electrode materials.

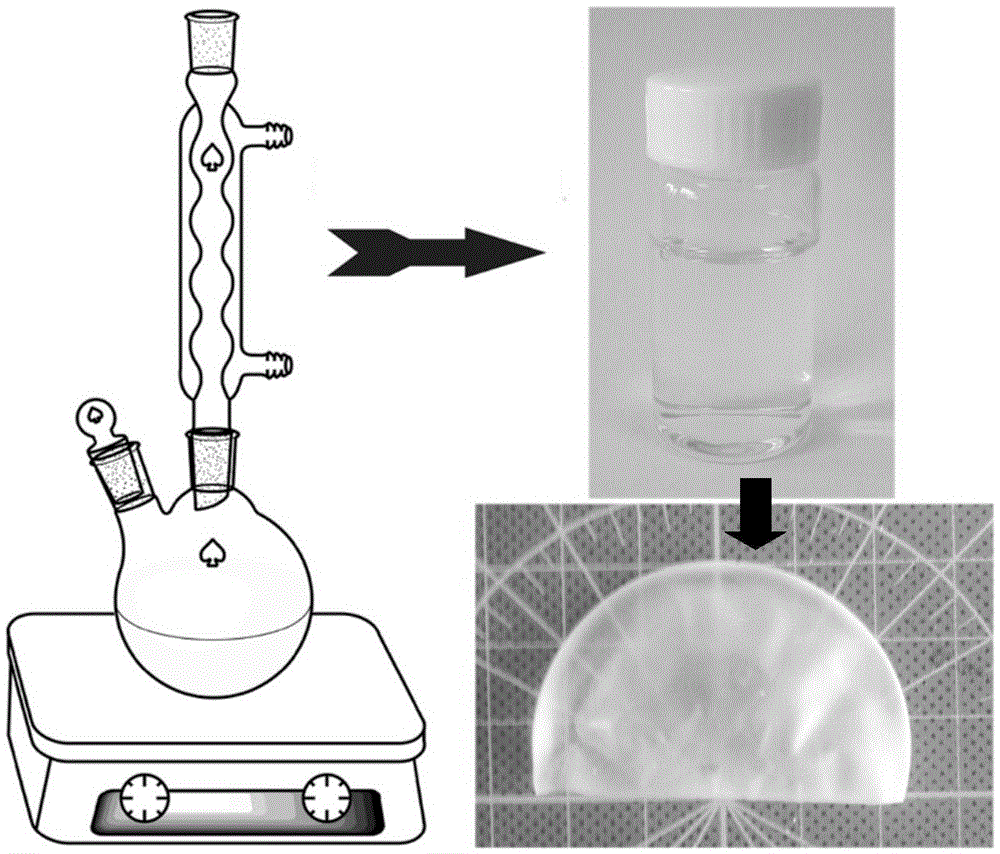

[0051] In a typical embodiment of the present invention, a process for preparing a modified PVA gel electrolyte flexible supercapacitor based on the "one-pot" method may include: adding PVA to the aqueous solution, heating and stirring until it is dissolved, and then adding the modified filler (Silica, modified silica, montmorillonite, modified montmorillonite, etc.), continue to stir until the mixture is evenly mixed and then cool down, add the inorganic salt solution (sodium chloride, sodium hydroxide, potassium chloride, hydrogen Potassium oxide, etc.) is completely dissolved, and the modified PVA gel electrolyte is obtained after it is cooled to room temperature; ...

Embodiment 1

[0053] Example 1: Weigh 6g of PVA and pour it into a flask containing 54mL of deionized water, stir on a magnetic stirrer with heating function, set the initial reaction temperature to 88°C, and stir in circulating condensed water After 2h, it was completely dissolved, and a PVA aqueous solution with a mass fraction of 10% was obtained. After the reaction temperature dropped to 60°C, 1.5 parts of montmorillonite dispersed in 10 mL of deionized water was poured into the reaction flask, and stirring was continued for 5 hours until the mixture was uniform. Maintaining the reaction temperature, slowly drip 3 g of potassium hydroxide electrolyte dissolved in 10 mL of deionized water into the reaction flask, continue to stir for 2 hours, turn off heating, and naturally cool to room temperature to obtain a modified PVA gel electrolyte.

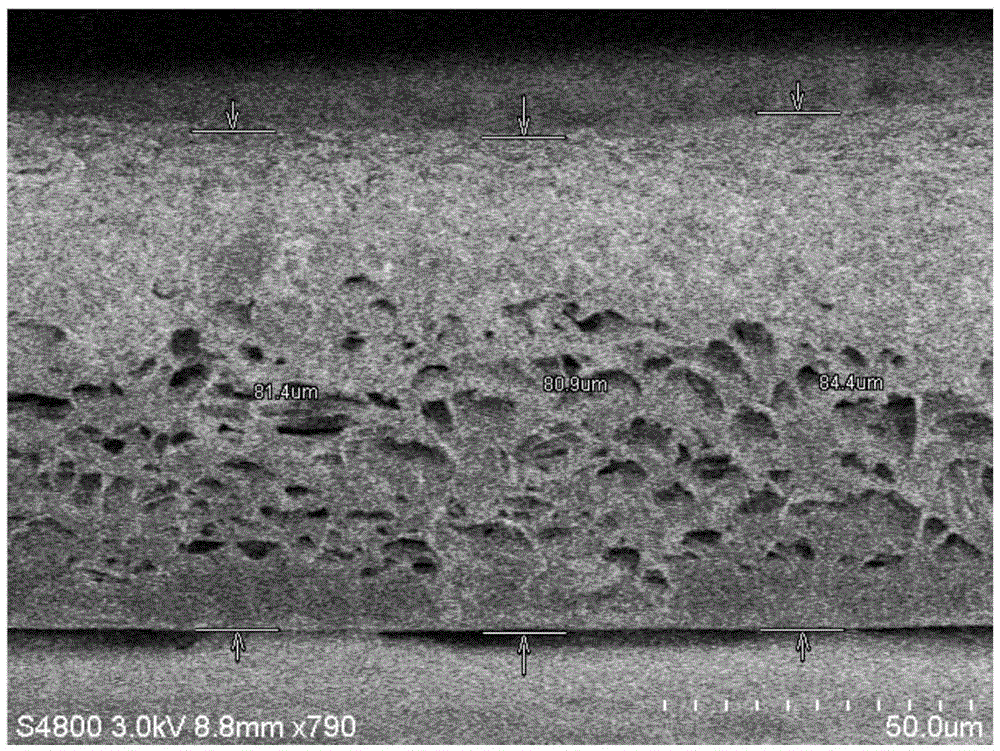

[0054] After the modified PVA gel electrolyte is spin-coated on a glass sheet and dried, the modified electrolyte solid film can be obtained for testin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com