Waste diachylon desulphurization method

A lead paste, waste technology, applied in waste collector recycling, battery recycling, recycling technology and other directions, can solve problems such as heavy burden and high energy consumption, and achieve the effect of increasing desulfurization conversion efficiency, improving desulfurization efficiency, and reducing time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

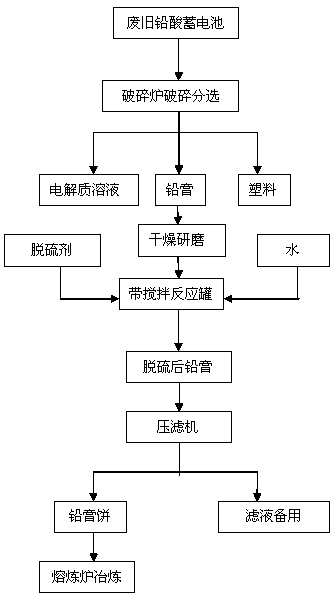

Image

Examples

Embodiment 1

[0034] Example 1: Take the broken and sorted lead paste (the S content is about 5.2% according to XRD quantitative analysis, so it is speculated that the lead sulfate content in the lead paste is about 50%) and dry at 120°C for 2 hours, and then preliminarily screen and remove The plastic particles in it are then subjected to strong grinding and screening, and the lead paste with a particle size of 300-350 μm is selected and added to the reaction tank, and Na 2 CO 3 As a desulfurization conversion agent, the reaction is carried out according to the following conditions: reaction time 30min, reaction temperature 40°C, reaction molar ratio 1:1, reaction liquid-solid ratio 1:1, lead paste particle size 300-350μm, stirring speed 200r / min. The reaction molar ratio is the molar ratio of the desulfurizing agent to the lead sulfate contained in the lead plaster, and the reaction liquid-solid ratio is the ratio of the mass of the desulfurizing agent aqueous solution to the mass of the ...

Embodiment 2

[0036] Example 2: First take 30.26g of broken and sorted lead paste and dry it at 120°C for 2 hours, then preliminarily screen and remove the plastic particles in it, then carry out strong grinding and screening, and select the lead paste with a particle size of 200-300 μm to add In the reaction tank, use (NH 4 )2 CO 3 As a desulfurization conversion agent, the reaction is carried out according to the following conditions: reaction time 40min, reaction temperature 50°C, reaction molar ratio 1.1:1, reaction liquid-solid ratio 2:1, lead paste particle size 200-300μm, stirring speed 200r / min. After the reaction, the analysis of the mixture shows that the desulfurization rate of the lead paste is about 92.0%.

Embodiment 3

[0037] Example 3: Take 30.26g of crushed and sorted lead paste and dry at 120°C for 2 hours, then preliminarily screen and remove the plastic particles in it, and then carry out strong grinding and screening, and select the lead paste with a particle size of 100-200 μm to add In the reaction tank, use NH 4 HCO 3 As a desulfurization conversion agent, the reaction is carried out according to the following conditions: reaction time 50min, reaction temperature 60°C, reaction molar ratio 1.2:1, reaction liquid-solid ratio 5:1, lead paste particle size 100-200μm, stirring speed 200r / min. After the reaction, the analysis of the mixture shows that the desulfurization rate of the lead paste is about 93.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com