Method for preparing glutaric acid through oxidation of glutaral pentanedial

A technology of glutaraldehyde and glutaric acid, which is applied in the field of glutaraldehyde oxidation to prepare glutaric acid, which can solve the problems of high price, high production cost, and difficulty in recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

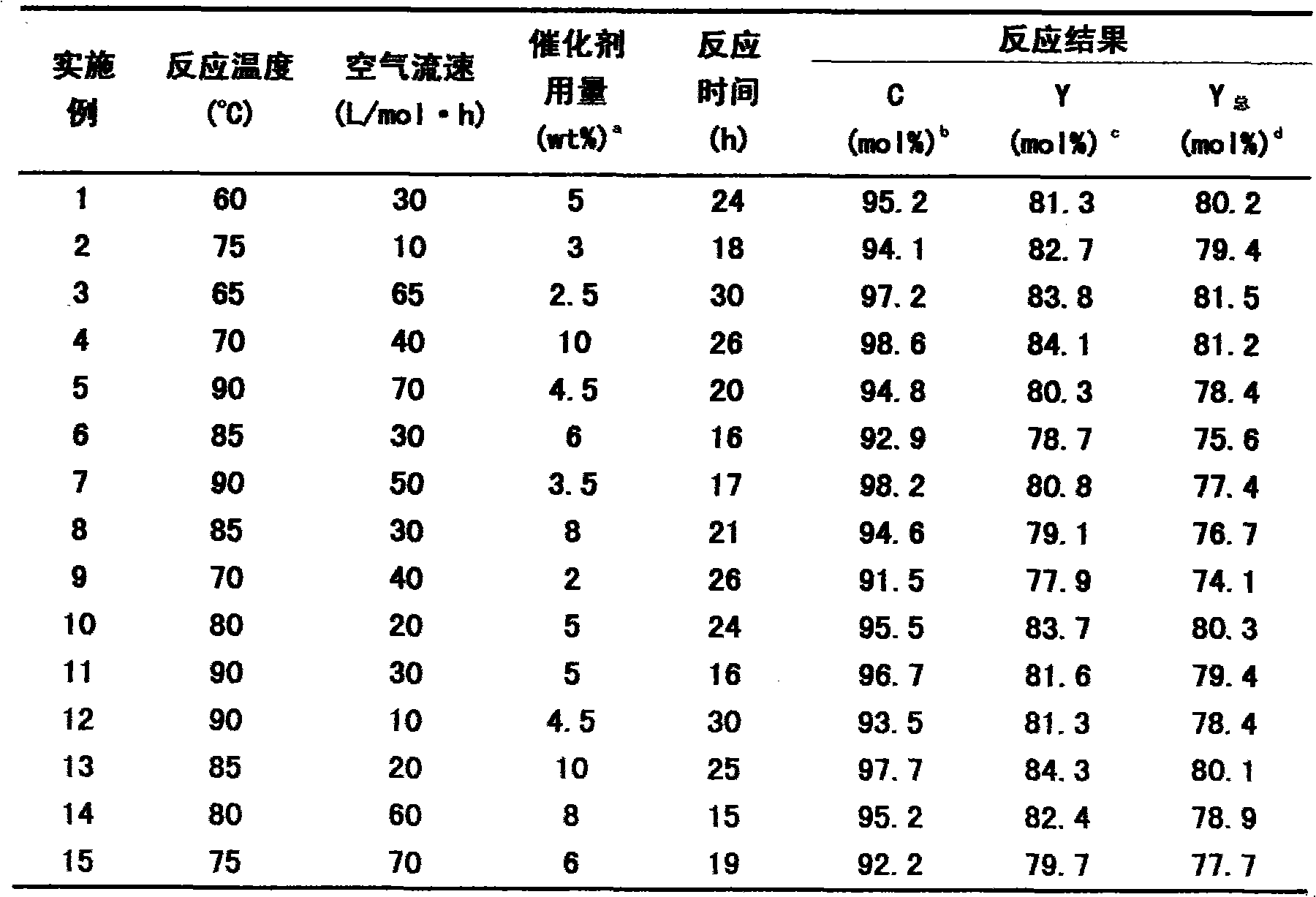

Examples

Embodiment 1~15

[0013] Catalyst preparation by co-impregnation method: Prepare a mixed aqueous solution with metered palladium nitrate, palladium chloride or palladium acetate and the soluble salt of component M, impregnate the carrier that has been shaped into 20-40 meshes and let it stand for 8 hours, and slowly evaporate to dryness at 75°C Moisture content, dried in an oven at 120°C for 12 hours, roasted at 500°C, the roasting atmosphere is nitrogen or air; after that, hydrogen is used for reduction treatment, the treatment conditions are: hydrogen pressure 0.5MPa, reduction time 2 hours, reduction temperature 400°C, hydrogen quality Airspeed 200h -1 . See Table 1 for the content of catalyst Pd and component M, M precursor, and calcination atmosphere in each embodiment.

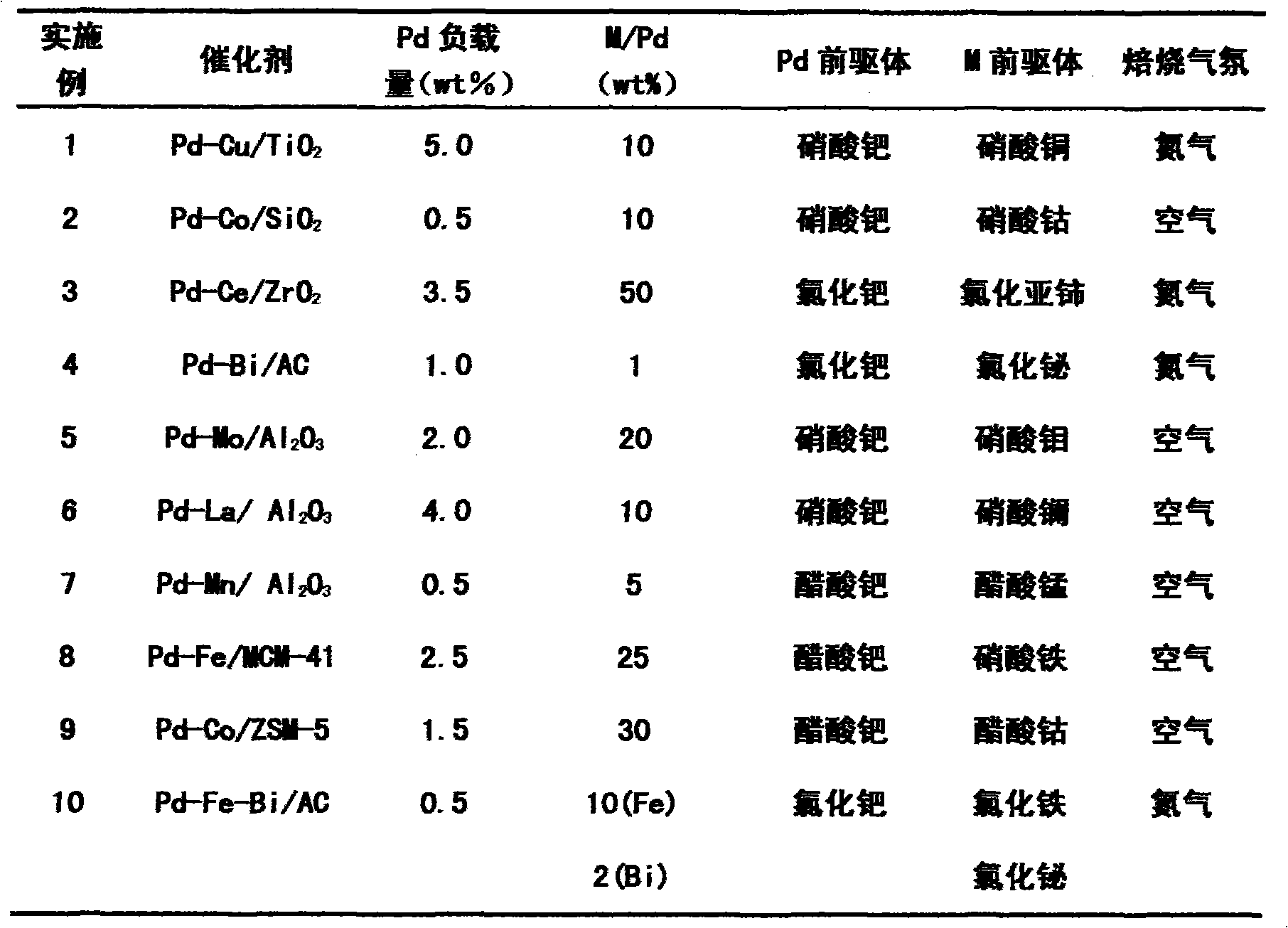

[0014] Table 1 Pd-M / A catalyst prepared by co-impregnation method

[0015]

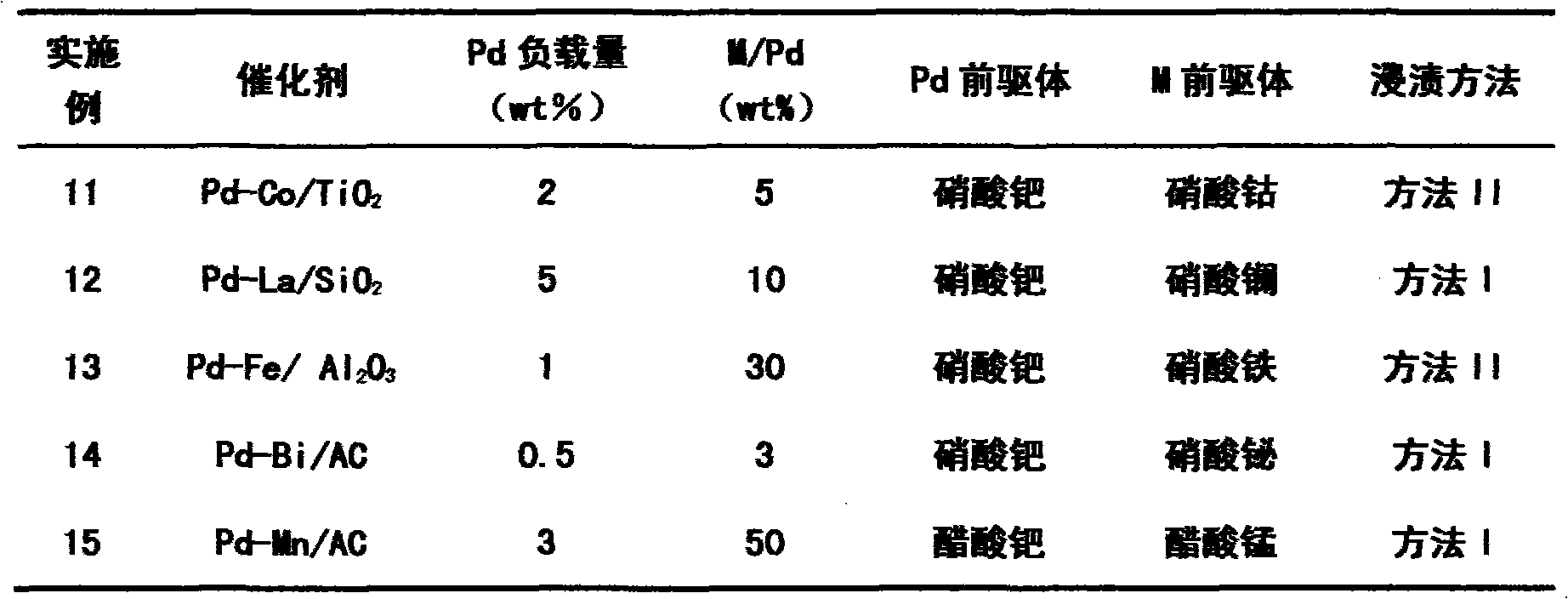

[0016] Catalyst preparation by step-by-step impregnation method: firstly make the measured palladium nitrate, palladium chloride or palladi...

Embodiment 16~18

[0031]The reacted product systems of Examples 12-14 were left to cool down to room temperature, and the catalyst naturally settled to the bottom of the reactor. Pour out the upper layer reaction solution, add the same material as the previous ratio to the reactor, and carry out the second reaction under the same reaction conditions, the reaction results are shown in Table 4.

[0032] The repeatability test of table 4 embodiment 12~14 catalyst

[0033]

[0034] Note: The meanings of the items in the table are the same as those in Table 3.

Embodiment 19

[0036] The product after the reaction of Example 18 was left to cool to room temperature, and the catalyst naturally settled to the bottom of the reactor. Pour out the upper reaction liquid, add the same material as the previous proportion to the reactor, and react under the same reaction conditions, the reaction results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com