Intermediate-temperature low-cesium fluoroaluminate brazing flux and preparation method thereof

A cesium fluoroaluminate and flux technology, which is applied in the field of medium-temperature and low-cesium fluoroaluminate flux and its preparation, can solve the problem of high content of noble metal salt CsF, the inability to realize large-scale industrial application, and the high price of flux. problems, to achieve the effect of easy large-scale industrial production, simple preparation method and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with examples, but the present invention is not limited to these examples.

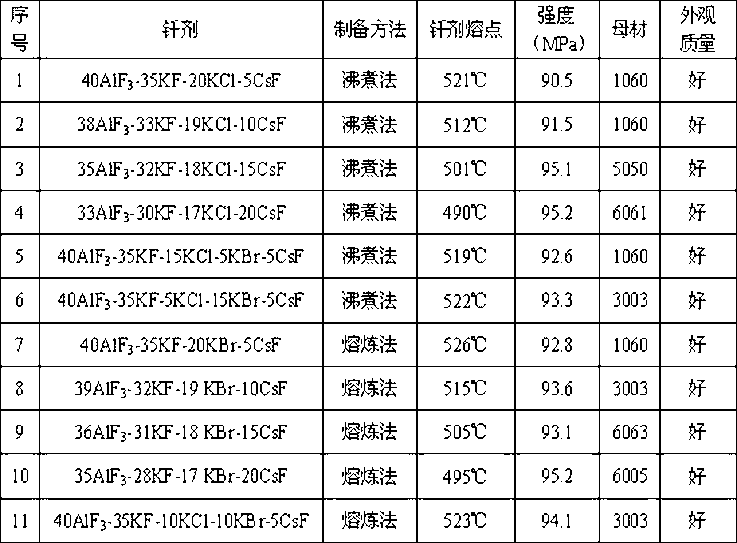

[0023] The concrete composition of brazing flux of the present invention is as table 1;

[0024] Flux 1~flux 6 in table 1 is prepared according to the first preparation method in the present invention, concrete steps are: the analytical pure reagent aluminum trifluoride, potassium fluoride, potassium chloride, potassium bromide, cesium fluoride Dehydrate at 300°C for 4 hours; then put it into a vacuum drying oven and dry for 12 hours at 110°C and a vacuum of -0.07MPa; after drying, grind the reagent into powder; (2) according to claim 1 Weigh out the reagent powder and put it into the crucible, add deionized water at 60°C~100°C to make a uniform mixture; (3) Put the crucible with the mixture into a crucible at 150°C~400°C Heat in the furnace until the mixture boils, and boil for 5-10 minutes, stirring continuously until the mixture evaporat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com