Surface modification method for polymer separation membrane

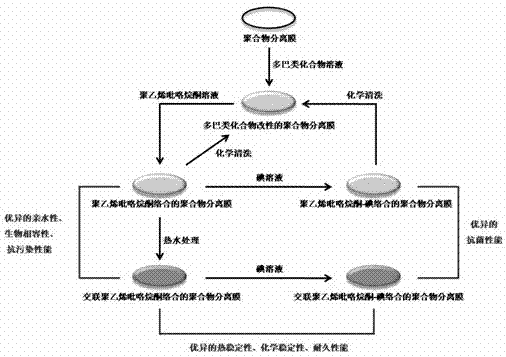

A surface modification and separation membrane technology, which is applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., to achieve the effect of simple modification equipment, good stability and durability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

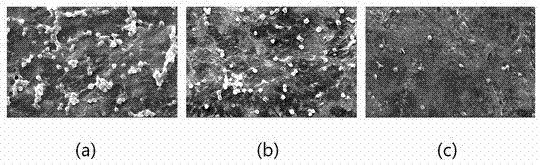

Embodiment 1

[0036] Dissolving dopamine in deionized water, dripping a sodium hydroxide solution with a concentration of 1 mol / liter, adjusting the pH value of the solution to 7.5, and obtaining a dopamine solution with a concentration of 1 gram / liter; Dissolve in deionized water to obtain a polyvinylpyrrolidone solution with a concentration of 0.5 to 5 g / L; cut out the washed and dried PE flat microfiltration membrane 5×5cm 2 , take it out after soaking in ethanol for 1 hour, immediately soak in dopamine solution to react, and form a self-polymerized dopamine composite layer on the membrane surface and membrane pore wall. permanent PE flat microfiltration membrane; soak the dopamine composite modified PE flat microfiltration membrane in polyvinylpyrrolidone solution, through the polyvinylpyrrolidone polyvinylpyrrolidone between the catechol group on the membrane surface and the polyvinylpyrrolidone lactam group Through hydrogen bonding, the polyvinylpyrrolidone is firmly complexed to the ...

Embodiment 2

[0041] Dissolving dopa in deionized water, dripping a sodium hydroxide solution with a concentration of 1 mol / liter, adjusting the pH value of the solution to 10, and obtaining a dopa solution with a concentration of 0.2 to 5 g / liter; Dissolve polyvinylpyrrolidone in deionized water to obtain a polyvinylpyrrolidone solution with a concentration of 2 g / L; cut 20 PVDF hollow fiber ultrafiltration membranes with a length of 10 cm, wash and dry them, and soak them in ethanol for 1 hour Take it out, soak it in the dopa solution immediately to react, and form a self-polymerized dopa composite layer on the surface of the membrane and the membrane hole wall. The PVDF hollow fiber ultrafiltration membrane; the dopa composite modified PVDF hollow fiber ultrafiltration membrane is soaked in polyvinylpyrrolidone solution, through the catechol group on the surface of the membrane and the lactam group in polyvinylpyrrolidone The polyvinylpyrrolidone is firmly complexed to the PVDF membrane ...

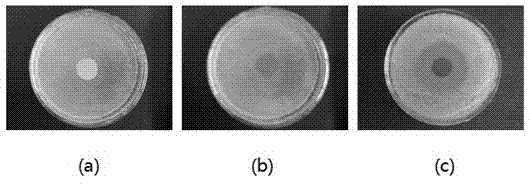

Embodiment 3

[0046] Dissolving dopamine in deionized water, dripping a sodium hydroxide solution with a concentration of 1 mol / liter, adjusting the pH value of the solution to 8.5, and obtaining a dopamine solution with a concentration of 2 grams / liter; Dissolve in deionized water to obtain a polyvinylpyrrolidone solution with a concentration of 2 g / L; dissolve elemental iodine in ethanol to obtain an iodine solution with a concentration of 10 to 100 g / L; cut the washed and dried PSF tablet Filter membrane 5×5cm 2 , take it out after soaking in ethanol for 1 hour, immediately soak in dopamine solution to react, and form a self-polymerized dopamine composite layer on the membrane surface and membrane pore wall. PSF flat-panel nanofiltration membrane; the dopamine-modified PSF flat-panel nanofiltration membrane is soaked in polyvinylpyrrolidone solution, through the polyvinylpyrrolidone polyvinylpyrrolidone between the catechol group and the polyvinylpyrrolidone polyvinylpyrrolidone. Polyvi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com