Thin-film solar cell and method for preparing same

A solar cell and thin film technology, applied in the field of solar cells, can solve the problems of low interface photo-generated carrier recombination probability, incompatibility of solar cell internal resistance, low photo-generated carrier recombination probability, etc., so as to reduce internal resistance and improve Output power, the effect of reducing the probability of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

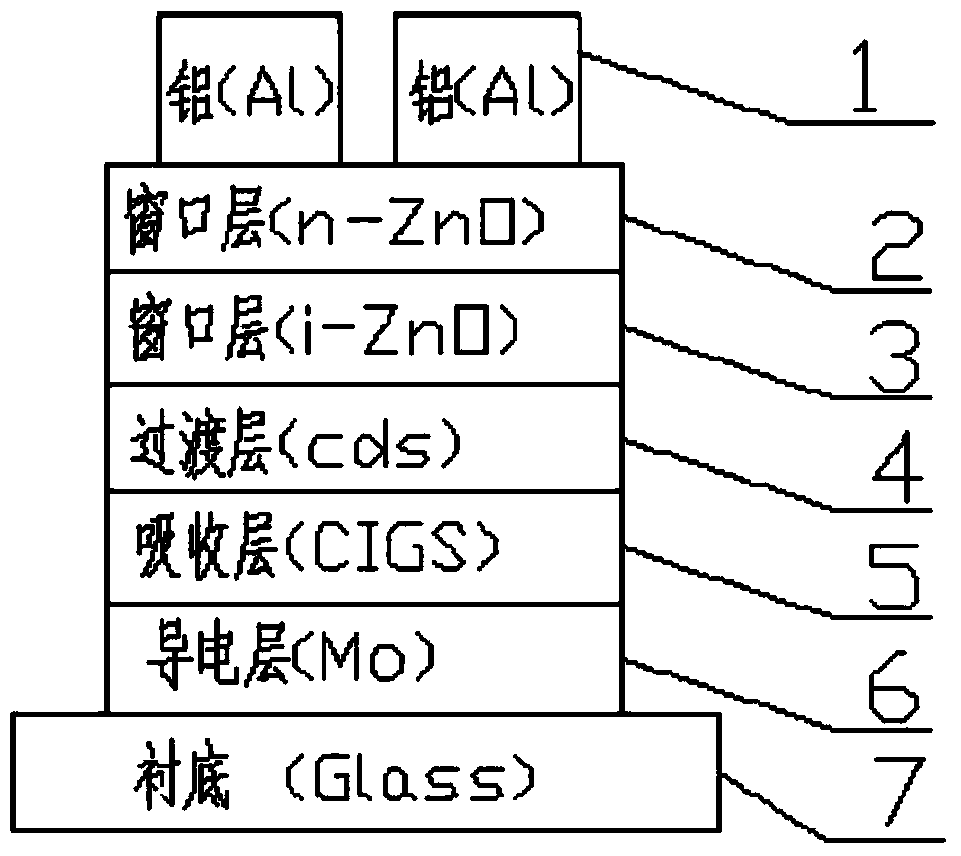

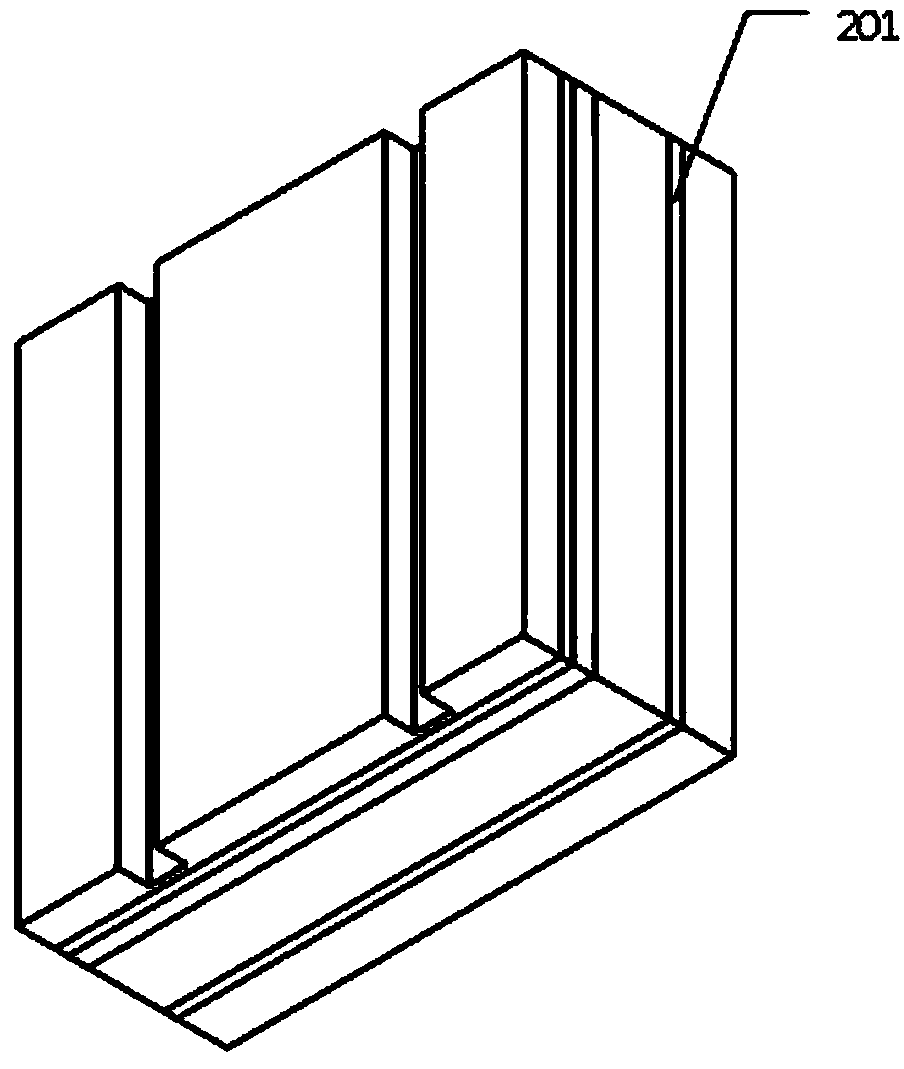

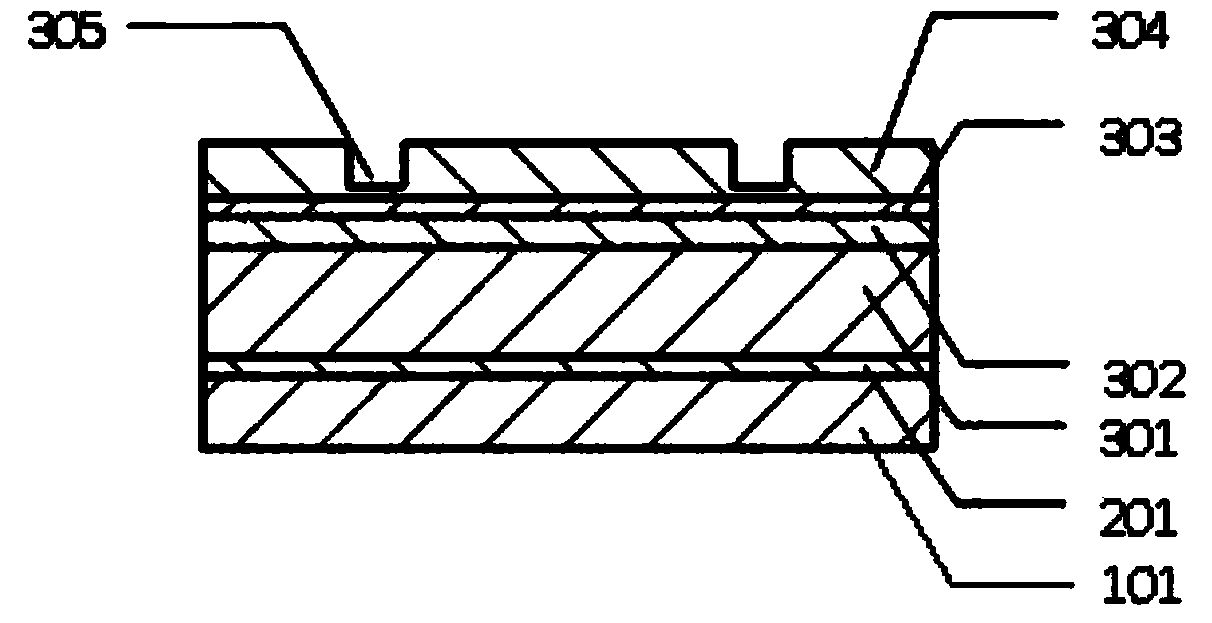

[0034] This embodiment provides a thin-film solar cell and a preparation method thereof, the thin-film solar cell includes a back electrode layer 201, a light absorbing layer 301, a buffer layer 302, and a high-resistance window layer 303 sequentially prepared in the vertical direction of a transparent substrate 101 , a low-resistance window layer 304 and a collection electrode 401; two electrode grooves 305 are formed on the low-resistance window layer 304, and the collection electrode 401 is deposited in the electrode groove 305 and exposed to the low-resistance Outside the plane where the window layer 304 is located; the depth direction of the electrode groove 305 is perpendicular to the plane where the low-resistance window layer 304 is located, and the depth of the electrode groove 305 is less than or equal to that of the buffer layer 302 and the high-resistance window layer. 303 and the sum of the thicknesses of the low-resistance window layer 304.

[0035] As other embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com