Porous polymer nanoparticles and preparation method thereof

A technology of porous polymers and nanoparticles, applied in the fields of alkali metal compounds, chemical instruments and methods, pharmaceutical formulations, etc., can solve the limitations of large particle size, biocompatibility and biodegradability, and it is difficult to reach the microporous scale and other issues to achieve the effect of easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

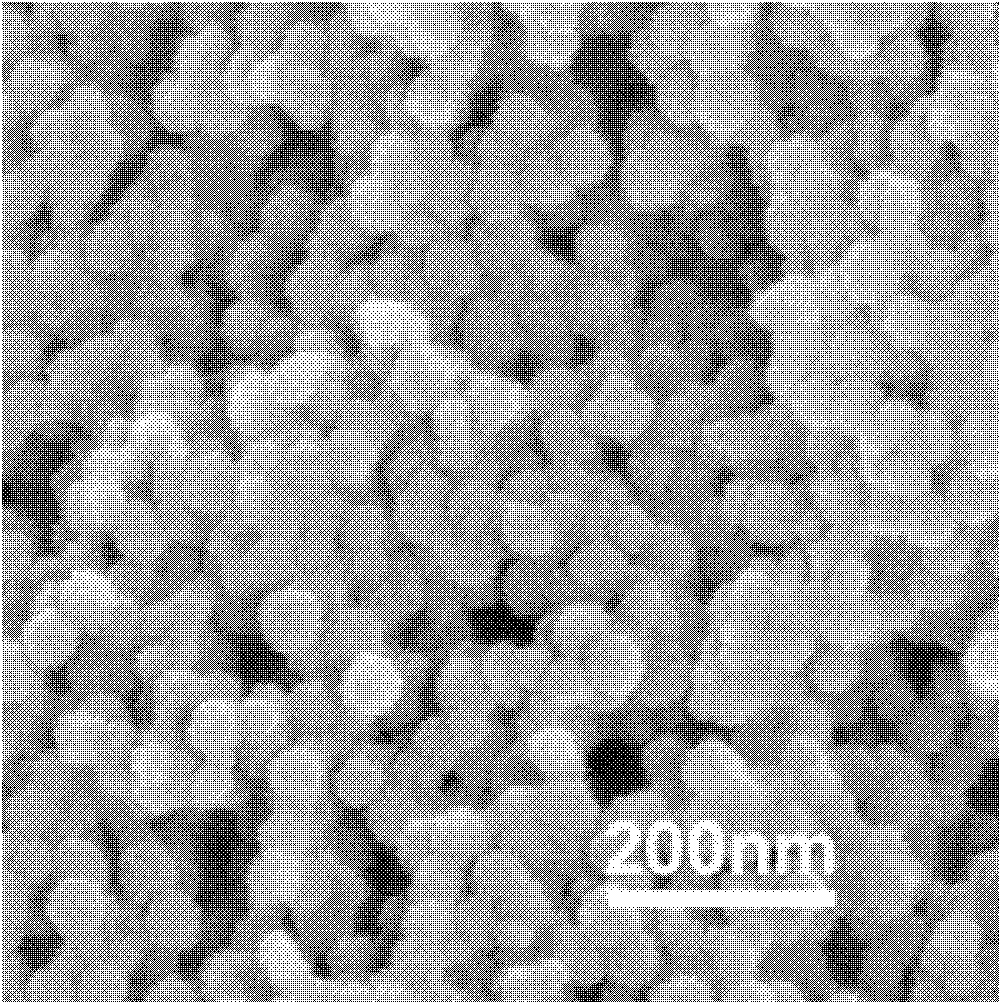

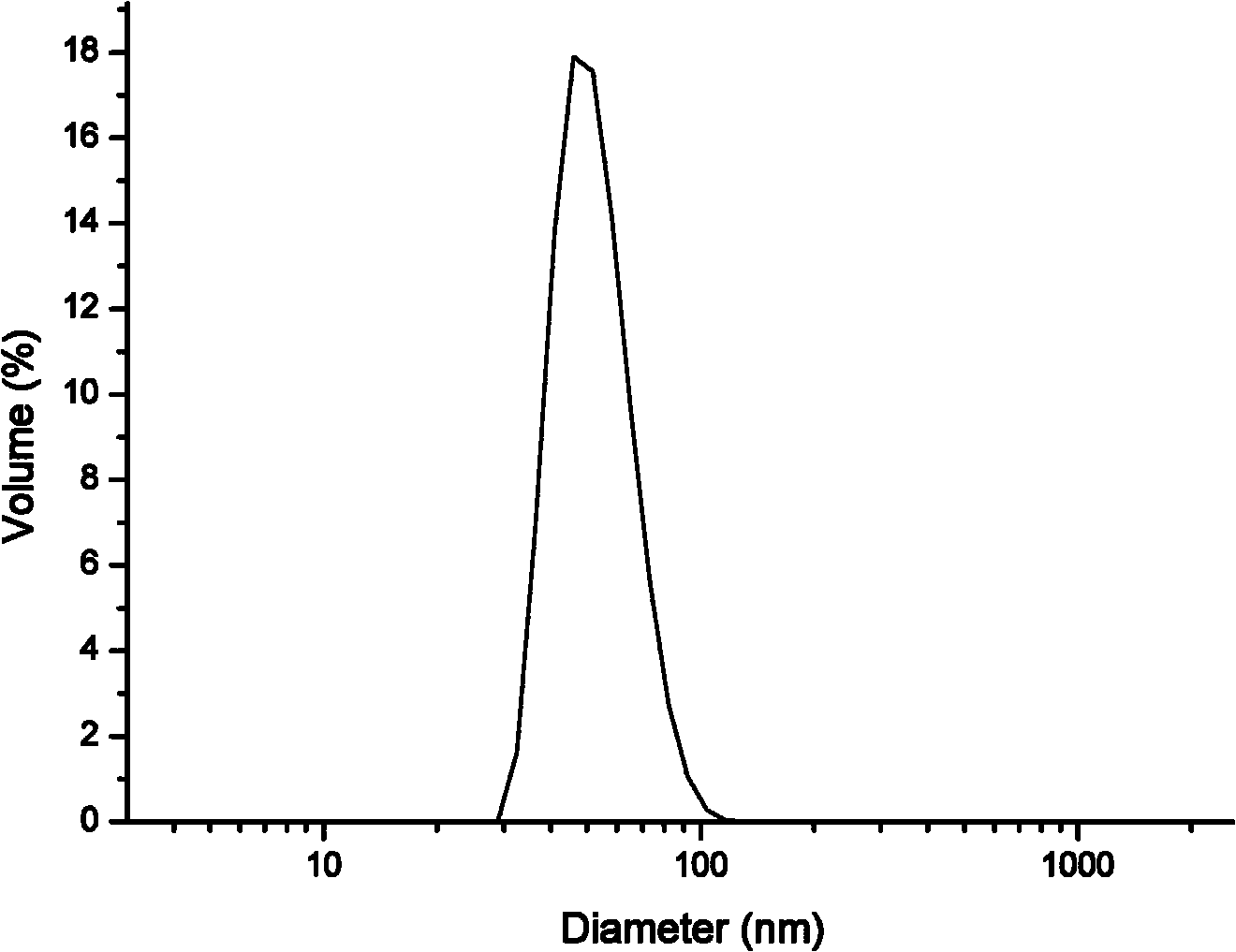

[0041] 1) Add 40ml of distilled water, a mixed monomer of 3.92g of chloromethylstyrene and 0.08g of divinylbenzene, and 0.16g of dodecyl to a four-necked flask equipped with a mechanical stirrer, a reflux condenser, a thermometer and a vent tube. sodium sulfate. During the process of pre-emulsification and emulsion polymerization, nitrogen gas was continuously passed, and mechanical stirring was performed at 425 rpm. At room temperature, pre-emulsify for 0.5-2 hours, then heat up to 60-80°C, add 0.04g of potassium persulfate in 5ml of distilled aqueous solution, keep the reaction for 6-10 hours, stop the reaction, and cool down to room temperature. The emulsion obtained by the reaction was demulsified with methanol, then centrifuged, filtered, and washed with distilled water to obtain a white solid product, which was lyophilized and dried for 24 hours, and the obtained white powder was a monodisperse porous polymer nanoparticle precursor.

[0042] 2) At room temperature, add ...

Embodiment 2

[0044] 1) Add 40ml of distilled water, a mixed monomer of 3.92g of styrene and 0.08g of divinylbenzene, and 0.08g of sodium dodecylsulfonate into a four-necked flask equipped with mechanical stirring, a reflux condenser, a thermometer and a vent tube . During the process of pre-emulsification and emulsion polymerization, nitrogen gas was continuously passed, and mechanical stirring was performed at 425 rpm. At room temperature, pre-emulsify for 0.5-2 hours, then heat up to 60-80°C, add 0.04g of ammonium persulfate in 5ml of distilled aqueous solution, keep the reaction for 6-10 hours, stop the reaction, and cool down to room temperature. The emulsion obtained by the reaction was demulsified with methanol, then centrifuged, filtered, and washed with distilled water to obtain a white solid product, which was lyophilized and dried for 24 hours, and the obtained white powder was a monodisperse porous polymer nanoparticle precursor.

[0045] 2) At room temperature, add 30ml of 1,2...

Embodiment 3

[0047] 1) Add 40ml of distilled water, a mixed monomer of 3.92g of 3-vinylaniline and 0.08g of divinylbenzene, and 0.08g of dodecyl sulfonate into a four-necked flask equipped with mechanical stirring, reflux condenser, thermometer and ventilation tube. Sodium acid. During the process of pre-emulsification and emulsion polymerization, nitrogen gas was continuously passed, and mechanical stirring was performed at 425 rpm. At room temperature, pre-emulsify for 0.5-2 hours, then heat up to 60-80°C, add 0.04g of ammonium persulfate in 5ml of distilled aqueous solution, keep the reaction for 6-10 hours, stop the reaction, and cool down to room temperature. The emulsion obtained by the reaction was demulsified with methanol, then centrifuged, filtered, and washed with distilled water to obtain a white solid product, which was lyophilized and dried for 24 hours, and the obtained white powder was a monodisperse porous polymer nanoparticle precursor.

[0048] 2) At room temperature, a...

PUM

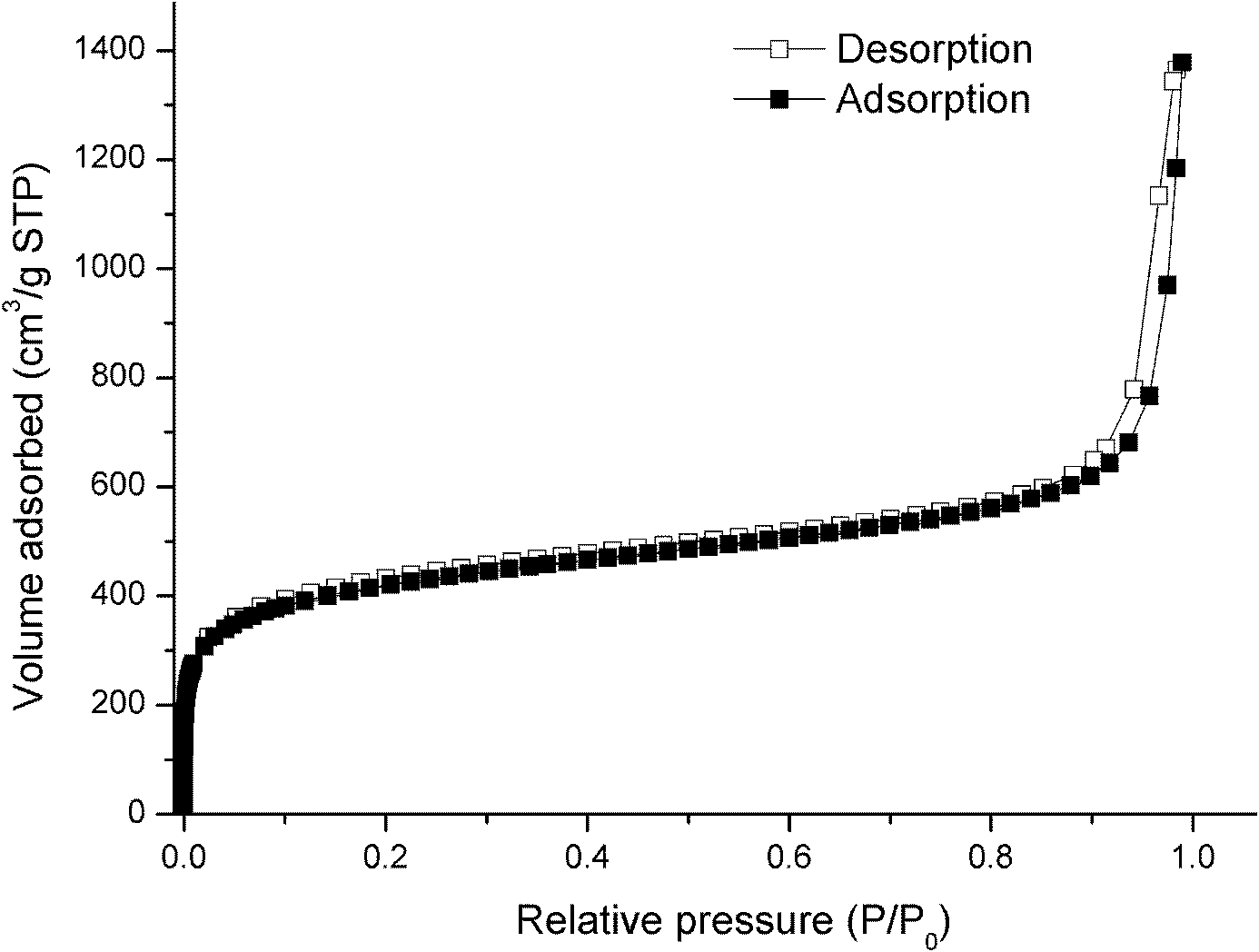

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com