Method for catalyst recovery and furfuryl alcohol clarification during furfuryl alcohol production

A production process and catalyst technology, applied in the chemical industry, organic chemistry, sustainable manufacturing/processing, etc., can solve the problems of poor catalyst separation effect, long cycle, poor effect, etc., to improve catalyst separation effect and reduce catalyst content , the effect of shortening the process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

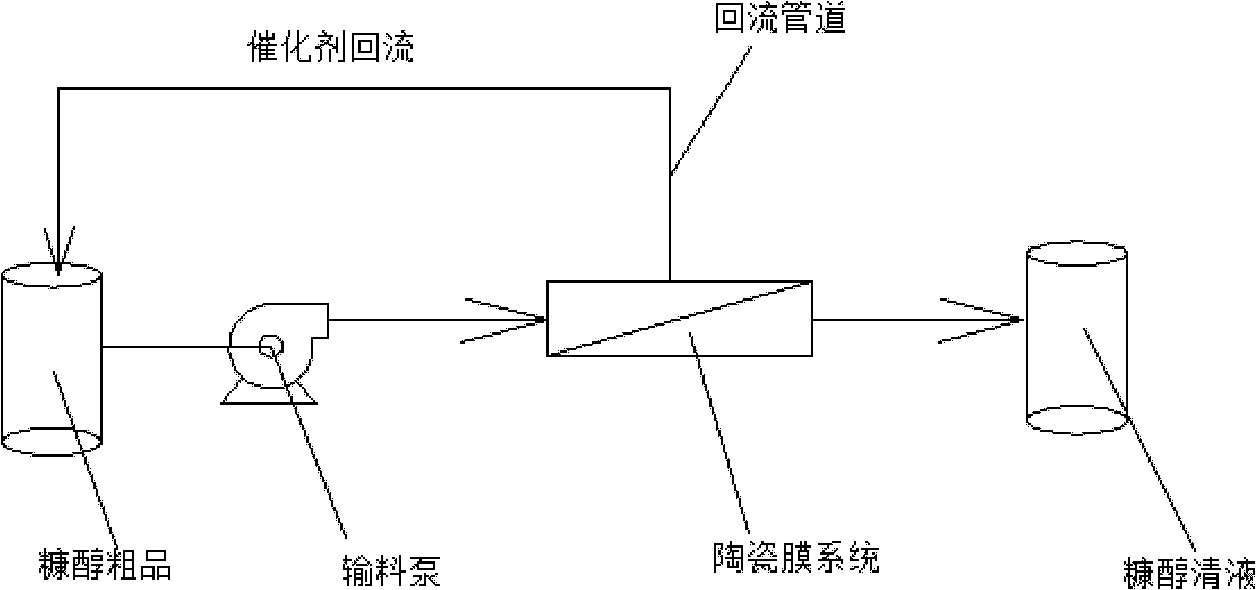

Image

Examples

Embodiment 1

[0017] In the furfuryl alcohol storage tank, the crude furfuryl alcohol contains 2% silicone catalyst, the average particle size of the catalyst is 5 μm, the ceramic membrane is made of aluminum oxide, the pore size is 800nm, and the working pressure is 0.1-0.5Mpa. In the production process, the crude furfuryl alcohol is transported to the ceramic membrane module through the feeding pump, the catalyst content in the dialysate is 0.18‰, the removal rate of the catalyst reaches 99.1%, and the clarity of the furfuryl alcohol solution is greatly improved.

Embodiment 2

[0019] In the furfuryl alcohol storage tank, the crude furfuryl alcohol contains 1.5% ketone chromium catalyst, the average particle size of the catalyst is 4 μm, the ceramic membrane is made of aluminum oxide, the pore size is 100 nm, and the working pressure is 0.1-0.5 Mpa. In the production process, the crude furfuryl alcohol is transported to the ceramic membrane module through the feeding pump, the catalyst content in the dialysate is 0.075‰, the removal rate of the catalyst reaches 99.5%, and the clarity of the furfuryl alcohol solution is greatly improved.

Embodiment 3

[0021] In the furfuryl alcohol storage tank, the crude furfuryl alcohol contains 1% silicone catalyst, the average particle size of the catalyst is 1 μm, the material of the ceramic membrane is aluminum oxide, the pore size is 200nm, and the working pressure is 0.1-0.5Mpa. In the production process, the crude furfuryl alcohol is transported to the ceramic membrane module through the feeding pump, the catalyst content in the dialysate is 0.08‰, the removal rate of the catalyst reaches 99.1%, and the clarity of the furfuryl alcohol solution is greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com