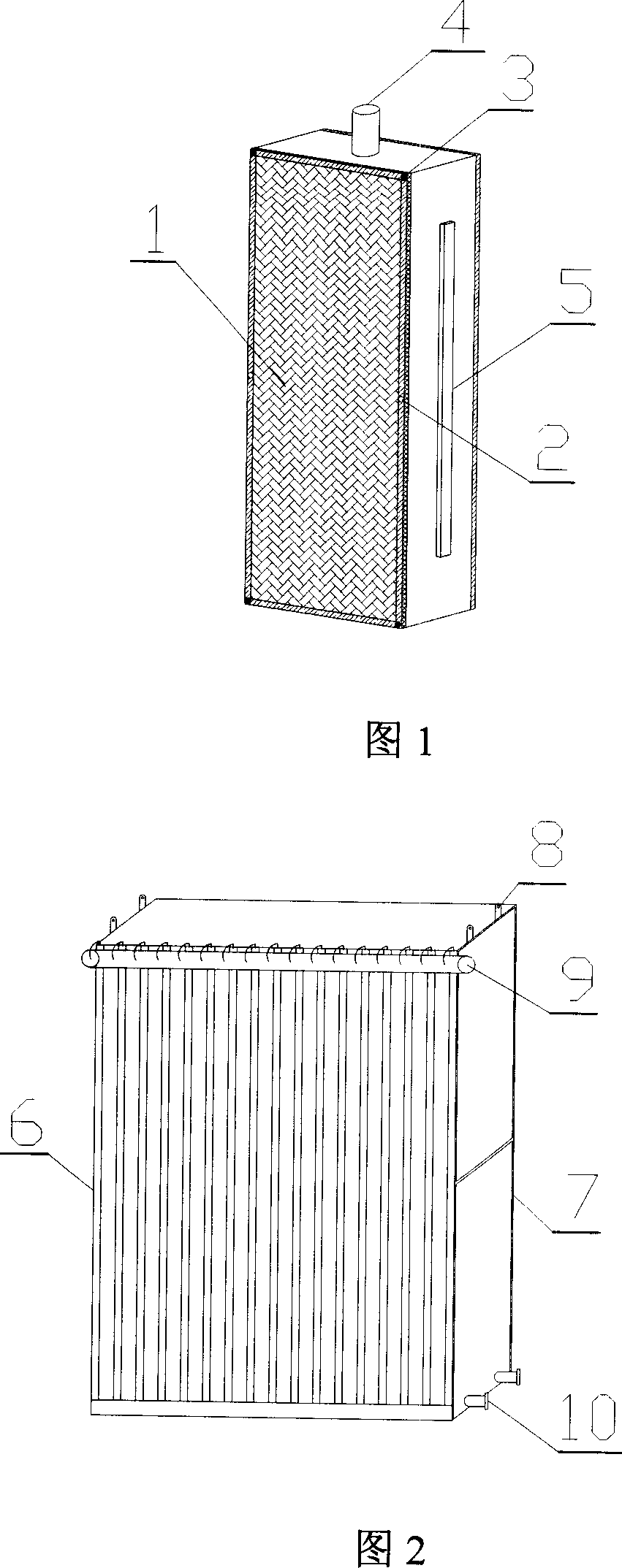

Bioreactor using polyvinyl alcohol nano microsphere dynamic film as filtration medium

A bioreactor and polyvinyl alcohol technology, applied in the field of environmental engineering, can solve the problems of dynamic membrane surface pollution, basement membrane pollution, damage, etc., and achieve the effects of reducing membrane pollution, preventing sedimentation, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

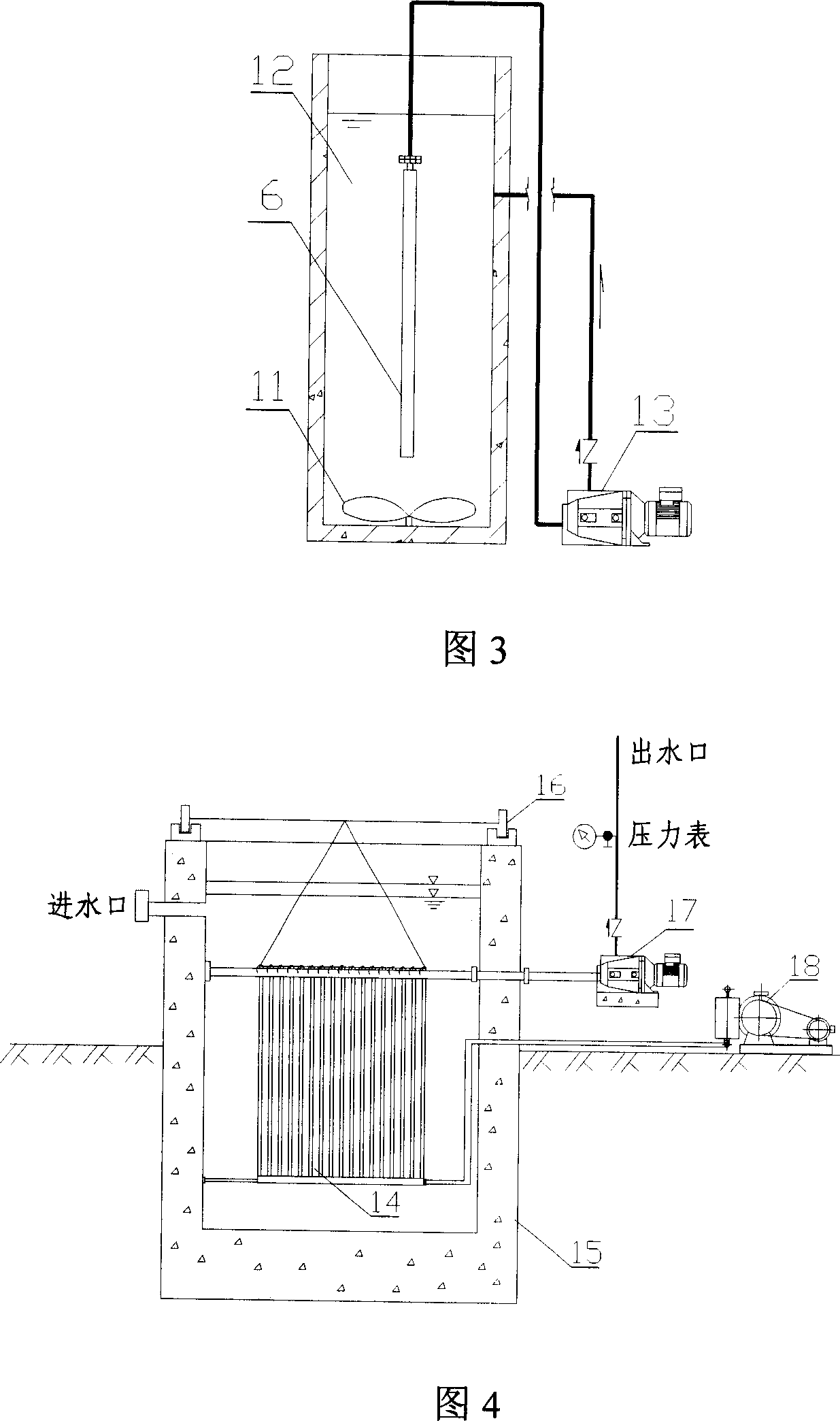

Method used

Image

Examples

Embodiment

[0023] At room temperature, accurately weigh quantitative Span 80 into a plastic container, add a certain volume of n-heptane, and stir to dissolve Span 80; add a certain concentration of PVA aqueous solution to make the oil-water phase volume ratio 3:2; Use a colloid mill to emulsify for 10 minutes at a rotating speed, and then use a low-speed water bath for magnetic stirring; add ether solution for extracting glutaraldehyde and 1 mL of concentrated hydrochloric acid to the emulsion at room temperature, stir for several minutes, then raise the temperature of the water bath to make the emulsion cool at 50°C Stirring was continued for 3h. After cross-linking, it was centrifuged, and ultrasonically cleaned several times with isopropanol, absolute ethanol and deionized water; dried in a blast oven at 55°C to obtain cross-linked polyvinyl alcohol microspheres with good dispersion.

[0024] Treatment of domestic sewage water volume according to 30m 3 / d, the COD concentration is 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com