Method for washing ultrafiltration membrane by combining ultrasonic waves and chemical cleaning agent

A chemical cleaning and ultrafiltration membrane technology, applied in the field of membrane cleaning, can solve the problems of secondary pollution application range, low cleaning efficiency, and high cost price, and achieve the effects of reducing dosage, saving cost, and reducing transmembrane pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

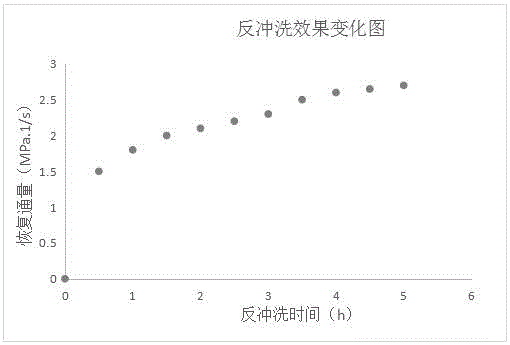

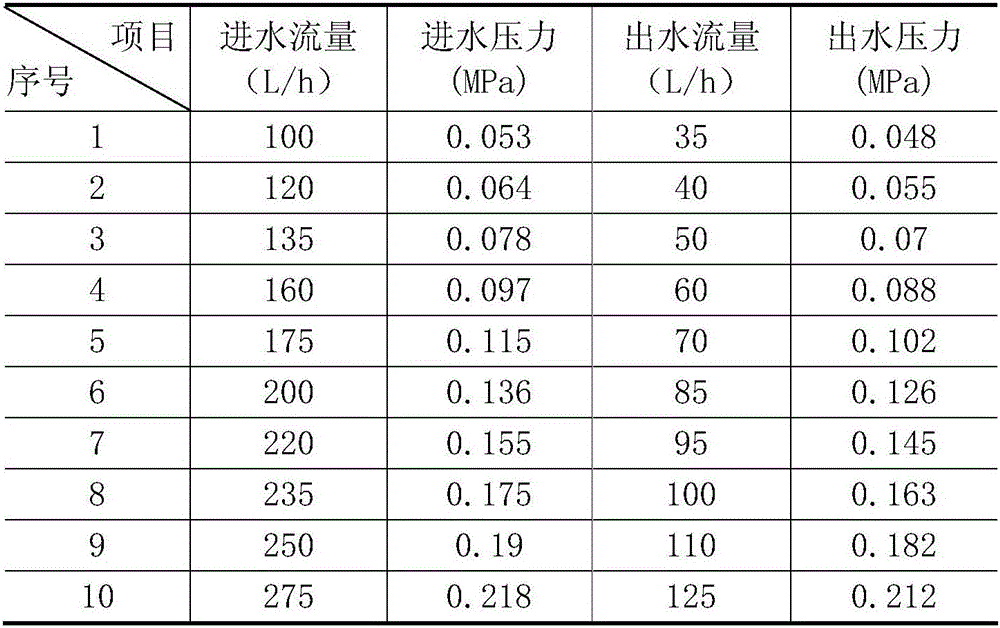

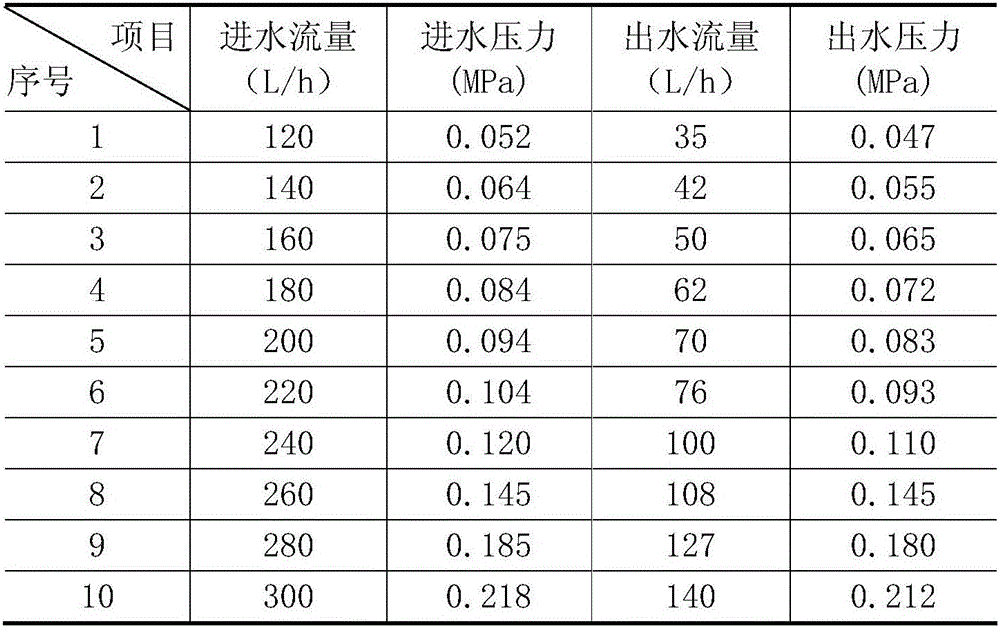

[0024] A method for cleaning an ultrafiltration membrane using ultrasonic waves combined with a chemical cleaning agent, specifically comprising the following steps:

[0025] Firstly, backwash the ultrafiltration membrane with air and water for 10 minutes, and then discharge all the sewage in the ultrafiltration membrane module; prepare a chemical cleaning solution with a mass concentration of 0.05% sodium hypochlorite, inject it into the ultrafiltration membrane membrane pool to submerge the membrane module, and soak for 2.5 hours ; Then filter, backwash cycle, and load frequency of 40kHz ultrasonic wave to assist chemical cleaning; finally inject a hydrochloric acid solution with a mass concentration of 0.1% to immerse the membrane assembly, soak for 2.5h, then filter, backwash cycle, and load frequency at the same time 30kHz ultrasonic assists in chemical cleaning;

[0026] After cleaning, the membrane flux of the ultrafiltration membrane can be restored to 94%, and the tra...

Embodiment 2

[0028] A method for cleaning an ultrafiltration membrane using ultrasonic waves combined with a chemical cleaning agent, specifically comprising the following steps:

[0029] Firstly, backwash the ultrafiltration membrane with air and water for 12 minutes, and then discharge all the sewage in the ultrafiltration membrane module; prepare a chemical cleaning solution with a mass concentration of 0.1% sodium hypochlorite, inject it into the ultrafiltration membrane membrane pool to submerge the membrane module, and soak for 3 hours; Then carry out filtration, backwashing cycle, and at the same time load ultrasonic waves with a frequency of 50kHz to assist chemical cleaning; finally inject a hydrochloric acid solution with a mass concentration of 0.15% to immerse the membrane assembly, soak for 3h, then perform filtration, backwash cycle, and load a frequency of 50kHz at the same time Ultrasonic assisted chemical cleaning;

[0030] After cleaning, the membrane flux of the ultrafil...

Embodiment 3

[0032] A method for cleaning an ultrafiltration membrane using ultrasonic waves combined with a chemical cleaning agent, specifically comprising the following steps:

[0033] Firstly, backwash the ultrafiltration membrane with air and water for 15 minutes, and then discharge all the sewage in the ultrafiltration membrane module; prepare a chemical cleaning solution with a mass concentration of 0.15% sodium hypochlorite, inject it into the ultrafiltration membrane membrane pool to submerge the membrane module, and soak for 4 hours; Then filter, backwash cycle, and load frequency of 40kHz ultrasonic to assist chemical cleaning; finally inject a hydrochloric acid solution with a mass concentration of 0.2% to immerse the membrane assembly, soak for 4h, then filter, backwash cycle, and load frequency of 40kHz at the same time Ultrasonic assisted chemical cleaning;

[0034] After cleaning, the membrane flux of the ultrafiltration membrane can be restored to 95%, and the transmembran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com