Reclaimed water recycling reverse osmosis membrane cleaning agent

A reverse osmosis membrane and cleaning agent technology, which is applied in the field of reverse osmosis membrane cleaning agent and cleaning for reclaimed water reuse, can solve the problems of reverse osmosis membrane difficult to restore membrane flux, secondary pollution, and reduce the service life of reverse osmosis membrane. Achieve good biodegradability, prolong the service life of the membrane, and inhibit the growth of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

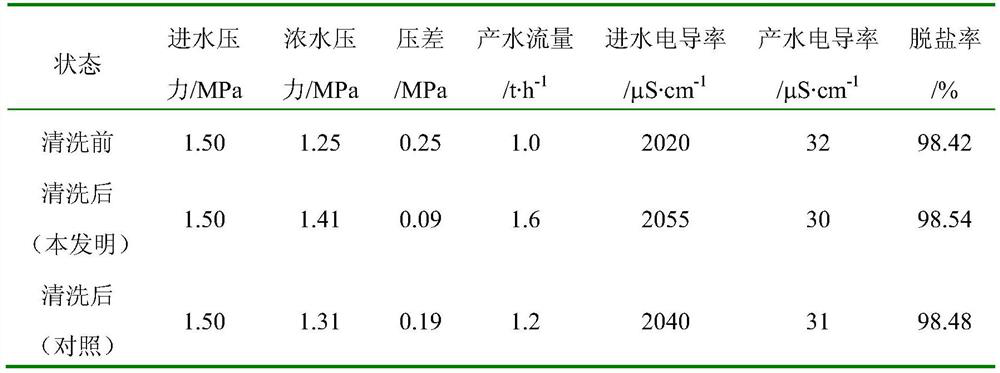

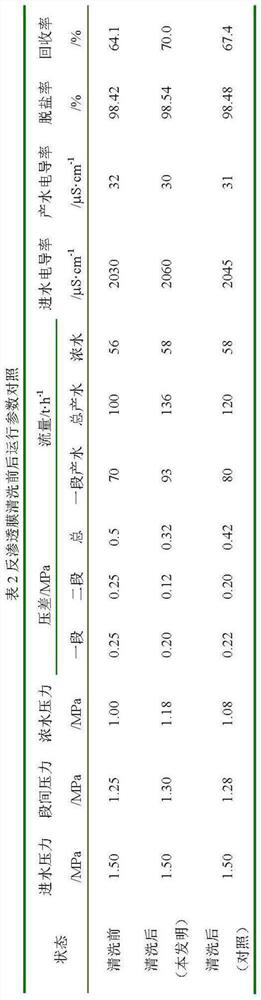

Examples

Embodiment 1

[0023] The reverse osmosis membrane cleaning agent for reclaimed water is composed of acidic cleaning components and alkaline cleaning components according to the following mass percentages:

[0024] (1) Acid cleaning agent: 0.05% hydrochloric acid, 0.2% organic acid, and the balance is water;

[0025] (2) Alkaline cleaning agent: 0.1% sodium hydroxide, 0.02% biosurfactant, 0.02% metal ion complexing agent, 0.02% bactericide, and the balance is water.

[0026] The organic acid is a mixture of sulfamic acid and citric acid at a mass ratio of 1:1; the biosurfactant is rhamnolipid; the metal ion complexing agent is ethylenediamine disuccinate tris A mixture of sodium and disodium edetate at a mass ratio of 1:1; the bactericide is a non-oxidative bactericide isothiazolinone; the water is reverse osmosis water.

[0027] The preparation method of described acid reverse osmosis cleaning agent is:

[0028] Step 1, get hydrochloric acid, sulfamic acid, citric acid and water respectiv...

Embodiment 2

[0035] The reverse osmosis membrane cleaning agent for reclaimed water is composed of acidic cleaning components and alkaline cleaning components according to the following mass percentages:

[0036] (1) Acid cleaning agent: 0.15% hydrochloric acid, 0.15% organic acid, and the balance is water;

[0037] (2) Alkaline cleaning agent: 0.15% sodium hydroxide, 0.03% biosurfactant, 0.04% metal ion complexing agent, 0.04% bactericide, and the balance is water.

[0038] The organic acid is a mixture of sulfamic acid and citric acid at a mass ratio of 1:1; the biosurfactant is rhamnolipid; the metal ion complexing agent is ethylenediamine disuccinate tris A mixture of sodium and disodium edetate at a mass ratio of 1:2; the bactericide is a non-oxidative bactericide isothiazolinone; the water is reverse osmosis water.

[0039] The preparation method is the same as in Example 1, the pH value of the final acid cleaning component is 1.8, and the pH value of the alkaline reverse osmosis me...

Embodiment 3

[0041] The reverse osmosis membrane cleaning agent for reclaimed water is composed of acidic cleaning components and alkaline cleaning components, respectively according to the following mass percentages:

[0042] (1) Acid cleaning agent: 0.2% hydrochloric acid, 0.1% organic acid, and the balance is water;

[0043] (2) Alkaline cleaning agent: 0.2% sodium hydroxide, 0.05% biosurfactant, 0.05% metal ion complexing agent, 0.05% bactericide, and the balance is water.

[0044] The organic acid is a mixture of sulfamic acid and citric acid at a mass ratio of 1:1; the biosurfactant is rhamnolipid; the metal ion complexing agent is ethylenediamine disuccinate tris A mixture of sodium and disodium edetate at a mass ratio of 1:1.5; the bactericide is a non-oxidative bactericide isothiazolinone; the water is reverse osmosis water.

[0045] The preparation method is the same as that in Example 1, the pH value of the final acidic reverse osmosis membrane cleaning agent is 1.5, and the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com