Cleaning method and cleaning apparatus for beer filtration ceramic membrane

A cleaning device and ceramic membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of increasing brewery operating costs, reducing equipment utilization, long cleaning time, etc., to shorten the cleaning process time, reduce water and electricity consumption, and save cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

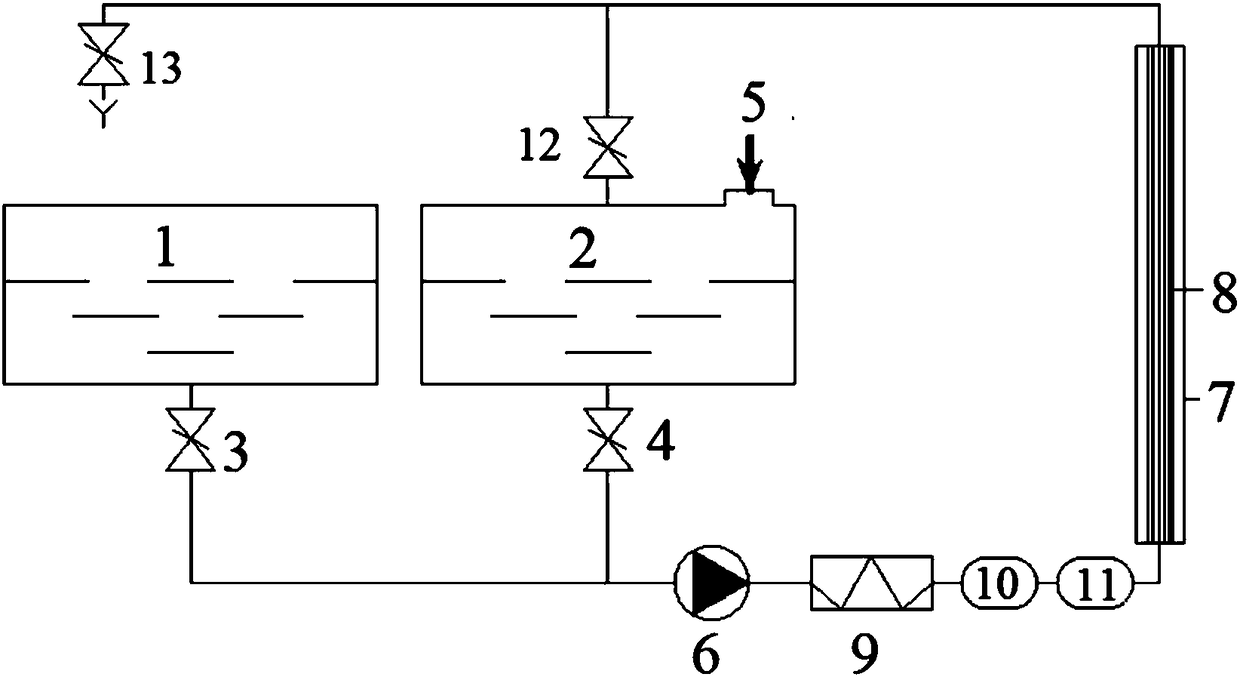

[0050] In embodiment 3, in addition to the device that embodiment 1 and embodiment 2 possess, flow meter 11 is installed between temperature measuring device 10 and ceramic membrane assembly 7 again, for measuring the flow rate when clear water passes ceramic membrane rod 8, and then The flow rate of clear water is controlled by the cleaning pump 6 . Depending on the cross-sectional area of the ceramic membrane rod 8, the selected cleaning flow rate is also different, and the specific flow rate can be calculated according to "cross-sectional area * flow rate * time". In this embodiment, the flow rate is further controlled at 2-3m / s. Too low a flow rate is not conducive to washing impurities in the ceramic membrane rod 8 with clean water. Too high a flow rate will have a greater impact on the device and generate greater noise. In this embodiment, the preferred clear water flow rate is 2.5m / s.

[0051] In addition, when the ceramic membrane itself has some impurities that are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com