Hollow fiber membrane cleaning agent and preparation method and application thereof

A fiber membrane and cleaning agent technology, applied in the field of membrane cleaning, can solve the problems of membrane pollution, shortened membrane life, increased content of inorganic iron salts and aluminum salts, etc., to speed up the reaction process, improve the cleaning effect, and save cleaning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Test materials:

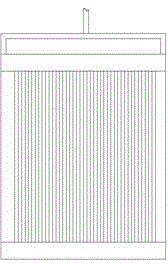

[0042] 1. Membrane module: PVDF hollow fiber membrane module such as figure 1 As shown, the length of the membrane filament is 0.45m, the inner diameter is 0.95mm, the outer diameter is 2.45mm, and the membrane pore diameter is 0.3μm, a total of 156 membrane filaments, and the membrane area is 0.5m 2 .

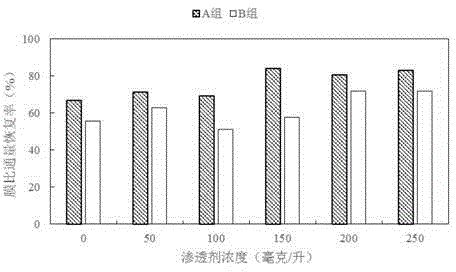

[0043] 2. Cleaning reagent: Keep the concentration of sodium hypochlorite constant, change the concentration and type of penetrant, and prepare hollow fiber membrane cleaning agents with 6 concentration gradients in groups A and B, and the volume of the cleaning solution is 40 liters. The composition of hollow fiber membrane cleaning agent is shown in Table 1.

[0044] Table 1 hollow fiber membrane cleaning agent concentration composition (unit: mg / liter)

[0045]

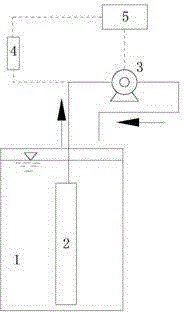

[0046] 3. Membrane specific flux measurement device: membrane specific flux measurement device such as figure 2 As shown, it includes a membrane module 2 , a peristaltic pump 3 ,...

Embodiment 2

[0055] 1. Test materials:

[0056] 1. Membrane module: Same as Example 1.

[0057] 2. Cleaning reagent: keep the mass concentration of sodium hypochlorite constant, change the concentration of complexing agent disodium EDTA, and prepare 6 cleaning solutions with different concentration gradients. The volume of the cleaning solution is 40 liters. The composition of hollow fiber membrane cleaning agent is shown in Table 2.

[0058] Table 2 hollow fiber membrane cleaning agent concentration composition (unit: mg / L)

[0059]

[0060] 3. Membrane specific flux measuring device: the same as in Example 1.

[0061] 2. Test method

[0062] 1. Measure the specific flux of the clean membrane. Using the membrane specific flux measurement test device (see figure 2 ) to measure the clear water flux of the clean membrane under different transmembrane pressure (TMP), the clear water temperature is 26°C-27°C, with TMP as the abscissa and the membrane flux as the ordinate, draw the cha...

Embodiment 3

[0069] 1. Test materials:

[0070] 1. Membrane module: Same as Example 1.

[0071] 2. Cleaning reagent: keep the mass concentration of sodium hypochlorite constant, change the concentration of penetrating agent AEP and complexing agent disodium EDTA, and prepare 6 kinds of hollow fiber membrane cleaning agents, the volume of cleaning solution is 40 liters. The composition of hollow fiber membrane cleaning agent is shown in Table 3.

[0072] Table 3 hollow fiber membrane cleaning agent concentration composition (unit: mg / L)

[0073] Cleaning reagent number

19

20

21

22

23

24

sodium hypochlorite

1000

1000

1000

1000

1000

1000

Penetrant AEP

0

0

150

75

100

100

complexing agent

0

100

0

50

150

150

[0074] 3. Membrane specific flux measuring device: the same as in Example 1.

[0075] 2. Test method

[0076] 1. Determination of the specific flux of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com