Treatment process of membrane bioreactor in nondegradable industrial wastewater

A membrane bioreactor and industrial wastewater technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of membrane flux decline, membrane pollution, The removal of total nitrogen is difficult to meet the emission standards, etc., to achieve the effect of increasing the air exposure process and improving the removal rate of total nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

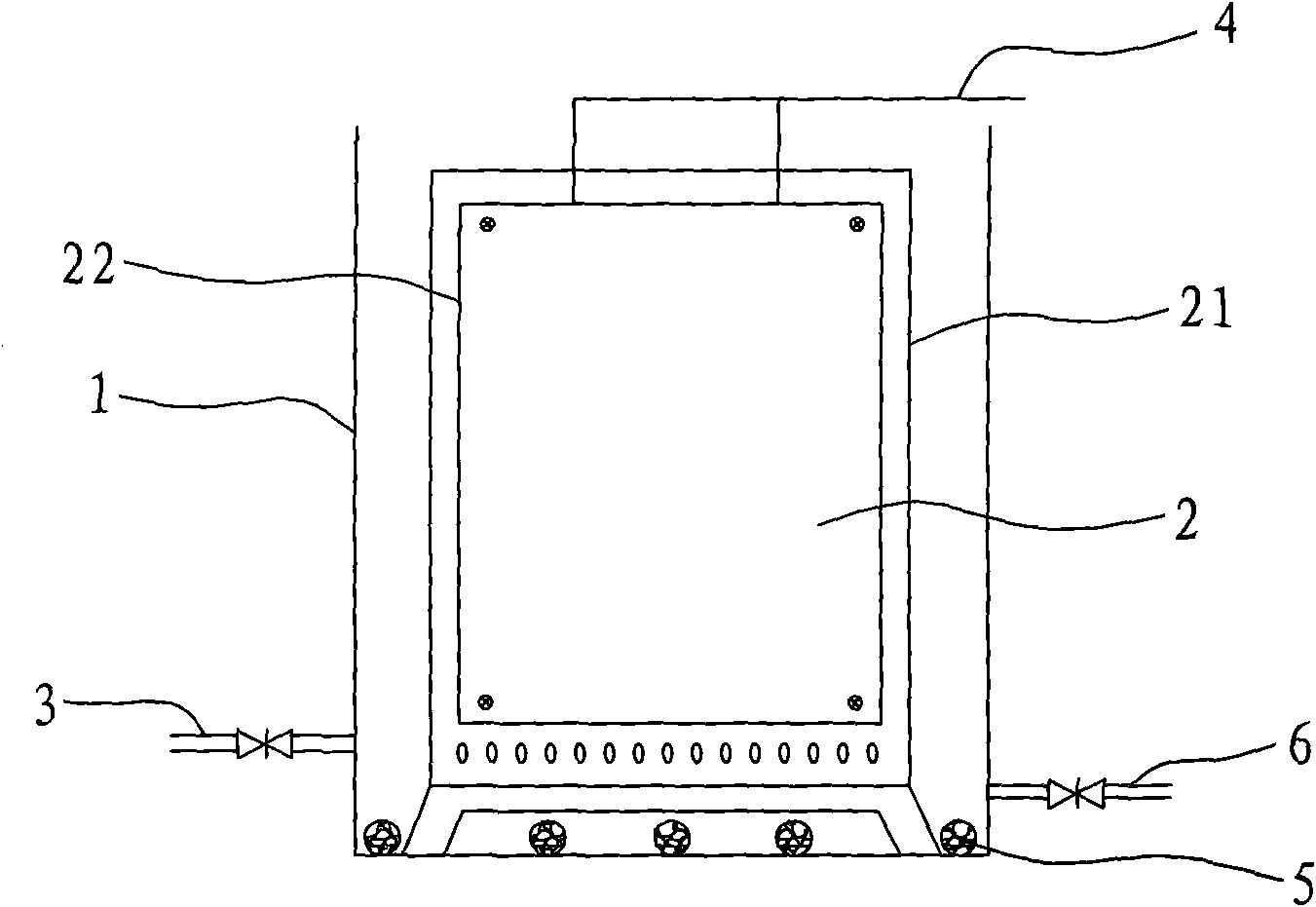

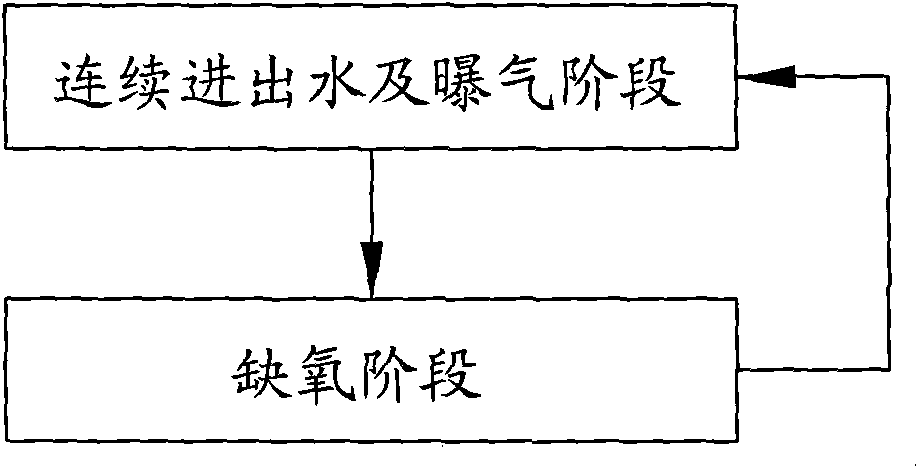

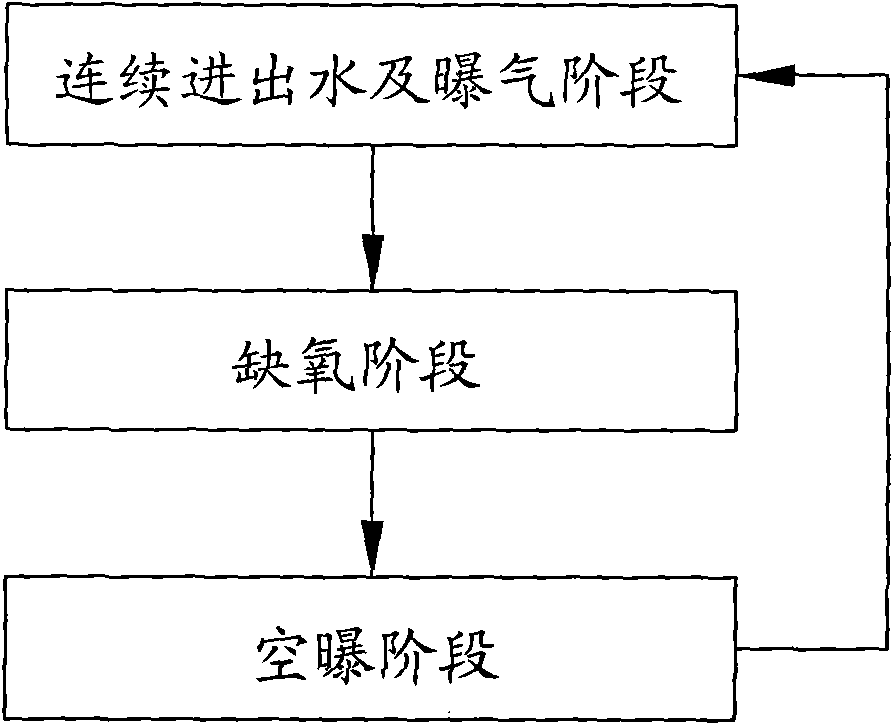

[0047] Disclosed by the present invention is a treatment process of membrane bioreactor in refractory industrial wastewater, such as figure 2 Shown is the process flow of the first preferred embodiment of the present invention. Described treatment process adopts traditional membrane bioreactor, and the structure of traditional membrane bioreactor can refer to as figure 1 As shown and referring to the background technology, its treatment process includes the following two stages:

[0048] 1. Continuous water in and out and aeration stage:

[0049] Water is continuously fed into the membrane bioreactor and pumped continuously, and the aeration pipe is aerated at the same time. In this stage, the waste water is biochemically treated and physically separated, and the obtained dialysate is discharged from the outlet pipe 4 . After this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com