Oil-water separating device and method based on carbon nanotube film

A technology of oil-water separation device and carbon nanotube membrane, which is applied in the field of oil-water separation equipment and oil-water separation device based on carbon nanotube membrane, can solve the problems of narrow application range and high cost, and achieve stable properties, stable chemical properties, and high separation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

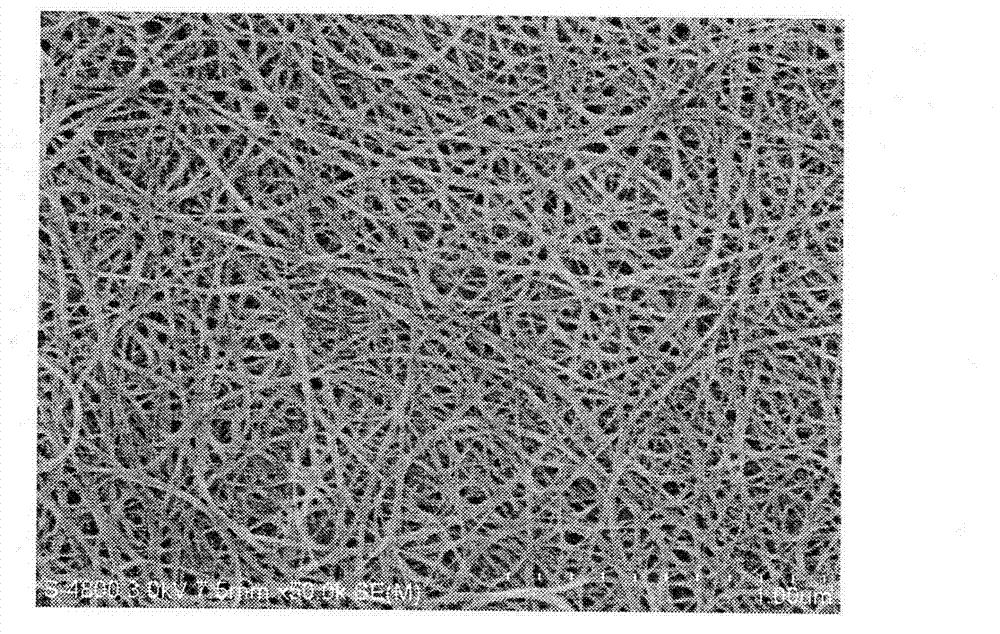

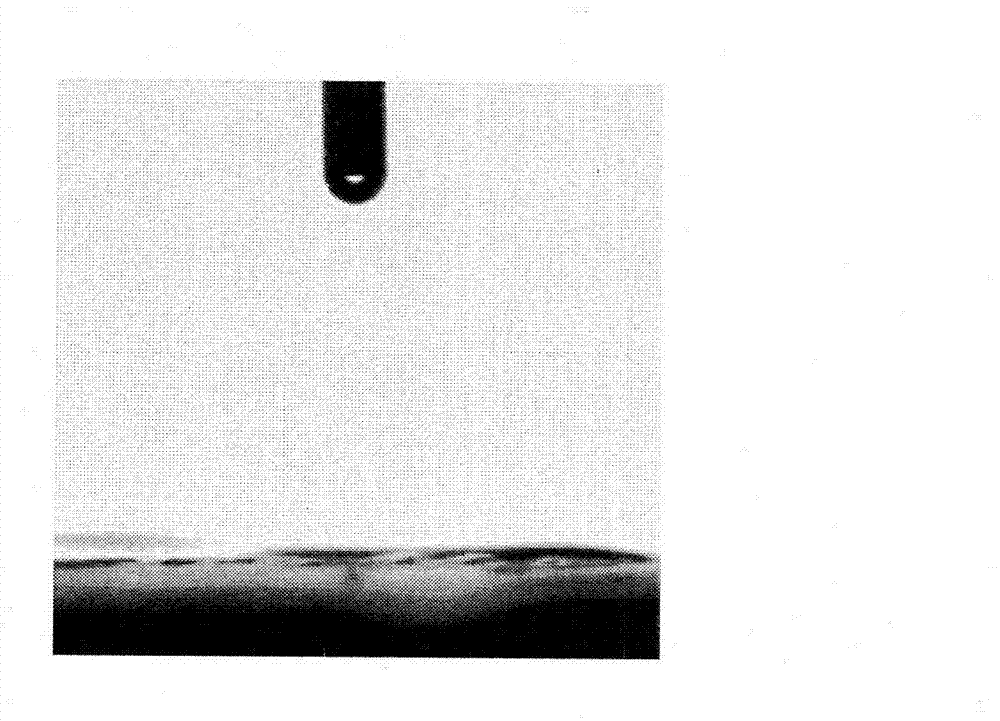

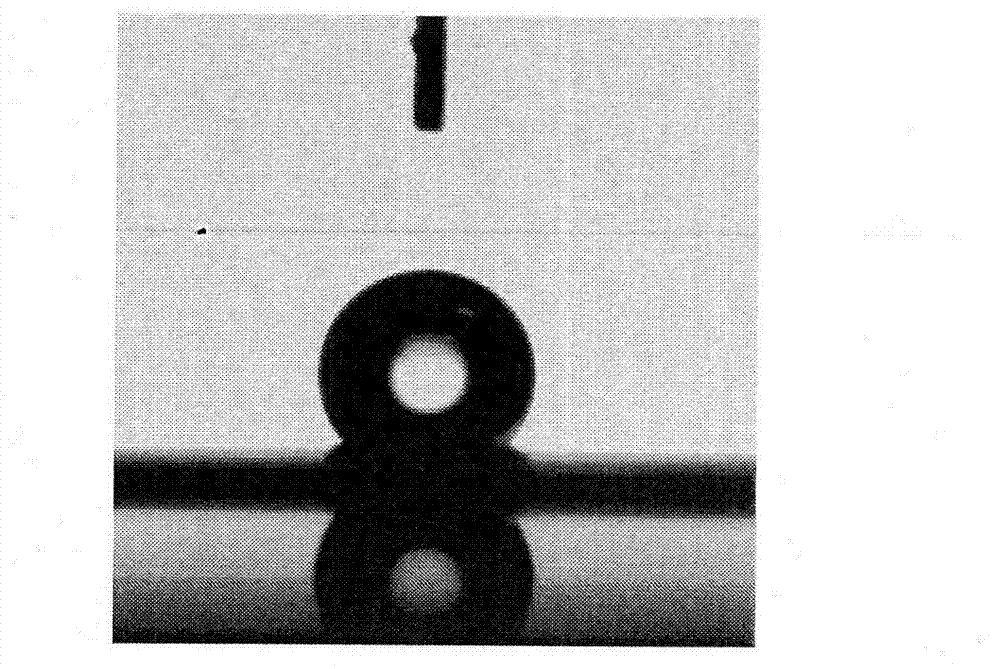

[0041] (1) Take an appropriate amount of carbon nanotubes dispersed in an aqueous solution, filter them into a membrane, and dissolve the substrate (such as a hydrophilic filter membrane) after drying. to obtain self-supporting carbon nanotube films (see figure 1 ). The carbon nanotube thin film obtained above is transferred to a ceramic membrane and placed in a separation container.

[0042] (2) Mix equal volumes of dichloromethane and water. After vigorous shaking, the stratification disappears, and then pour it into a separator. Under the action of pressure, the separation of dichloromethane and water is realized.

Embodiment 2

[0044] (1) Take an appropriate amount of carbon nanotubes dispersed in an aqueous solution, filter them into a membrane, and dissolve the substrate (such as a hydrophilic filter membrane) after drying. A self-supporting carbon nanotube film was obtained. The carbon nanotube thin film obtained above is transferred to a ceramic membrane and placed in a separation container.

[0045] (2) Mix dichloromethane and water with a volume ratio of 5:1. After vigorous shaking, the stratification disappears, and then pour it into a separator. Under the action of pressure, the separation of dichloromethane and water is realized.

Embodiment 3

[0047](1) Take an appropriate amount of carbon nanotubes dispersed in an aqueous solution, filter them into a membrane, and dissolve the substrate (such as a hydrophilic filter membrane) after drying. A self-supporting carbon nanotube film was obtained. The carbon nanotube thin film obtained above is transferred to a ceramic membrane and placed in a separation container.

[0048] (2) Mix dichloromethane and water with a volume ratio of 1:5. After vigorous shaking, the stratification disappears, and then pour it into a separator. Under the action of pressure, the separation of dichloromethane and water is realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com