Alternate two-stage aerobic membrane bioreactor

A technology of membrane bioreactors and reactors, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as long operation period, limited capacity, and discontinuous effluent , to achieve the effect of slowing membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

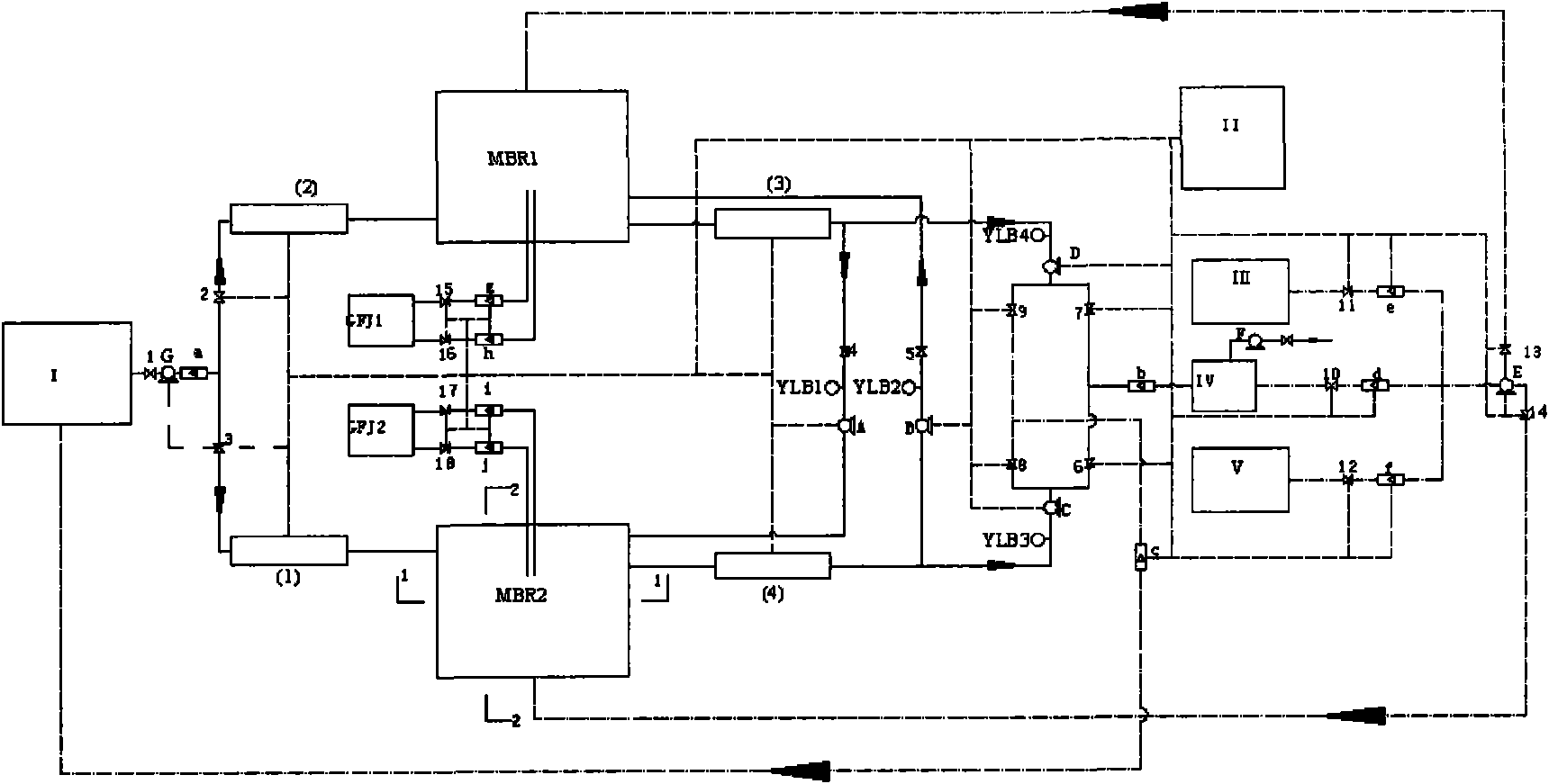

[0033] The present invention is described in more detail below in conjunction with accompanying drawing example:

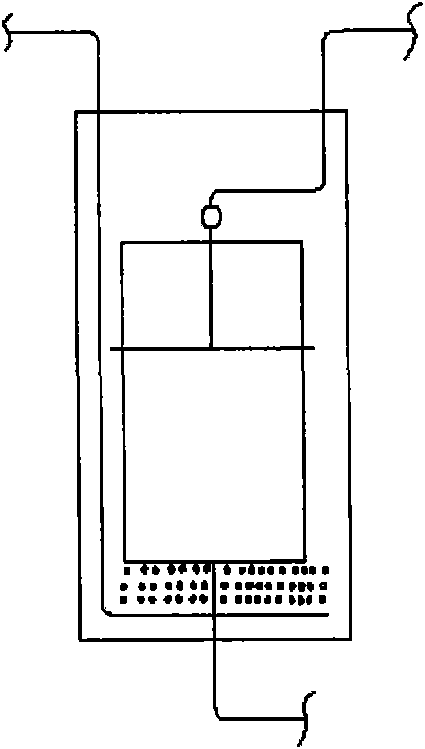

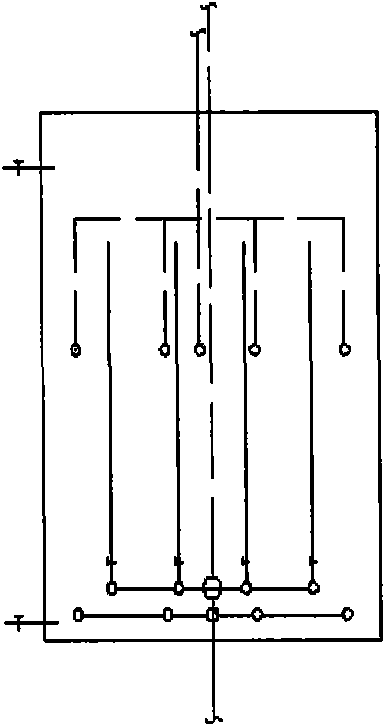

[0034] combine figure 1 , This set of equipment consists of the following components: membrane bioreactor MBR1, membrane bioreactor MBR2, regulating tank I, flow meter, valve, centrifugal pump, water storage tank IV, lye tank II, acid tank V, automatic control motor box Ⅱ. Blower GFJ1, blower GFJ2, perforated tube aeration device, shallow aeration device.

[0035] A valve 1, a centrifugal pump G and a flow meter a are connected to the water outlet of the regulating pool. The regulating tank and the first reactor MBR1 are connected by the water inlet pipeline, and the valve 2 and the second COD online measuring instrument are connected on the water inlet pipeline of the regulating pool and the first reactor MBR1, and the valve 2 and the second COD online measuring instrument are connected at the flow rate Between meter a and the first reactor MBR1. The regulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com