A2O (anaerobic-anoxic-oxic), MBR (membrane bio-reactor) and miniature animal bio-bed set for wastewater treatment and sludge reduction and application thereof

A technology for sludge reduction and sewage treatment, applied in biological water/sewage treatment, sustainable biological treatment, multi-stage water/sewage treatment, etc. Due to the large area of the sedimentation tank, the effect of reducing infrastructure costs and operating costs, efficient sewage treatment, and reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

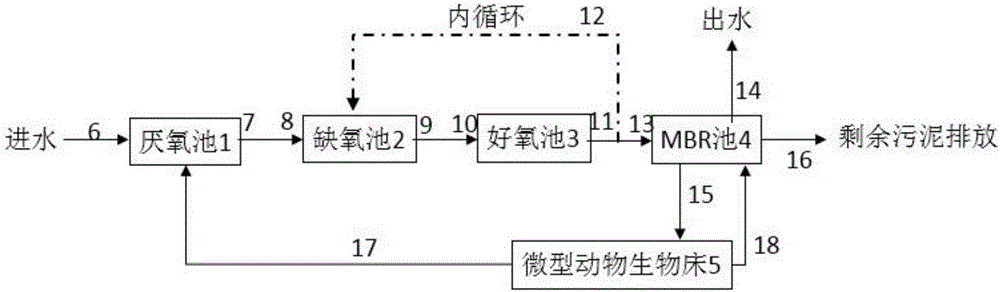

[0018] Specific implementation mode one: this implementation mode is described in conjunction with the figure, a kind of A of this implementation mode 2 O, the sewage treatment and sludge reduction combination device of MBR and micro-animal biological bed, it comprises: anaerobic pool 1, anoxic pool 2, aerobic pool 3, MBR4 and micro-animal biological bed 5; Wherein, anaerobic pool The water inlet of outlet pipe 7 is communicated with anaerobic pool 1, and the water outlet of anaerobic pool outlet pipe 7 is communicated with the water inlet of anoxic pool inlet pipe 8, and the water outlet of anoxic pool inlet pipe 8 is communicated with anoxic pool 2; The water inlet of the anoxic pool outlet pipe 9 communicates with the anoxic pool 2, the water outlet of the anoxic pool outlet pipe 9 communicates with the water inlet of the aerobic pool inlet pipe 10, and the water outlet of the aerobic pool inlet pipe 10 communicates with the aerobic pool 3 is connected; the water inlet of t...

specific Embodiment approach 2

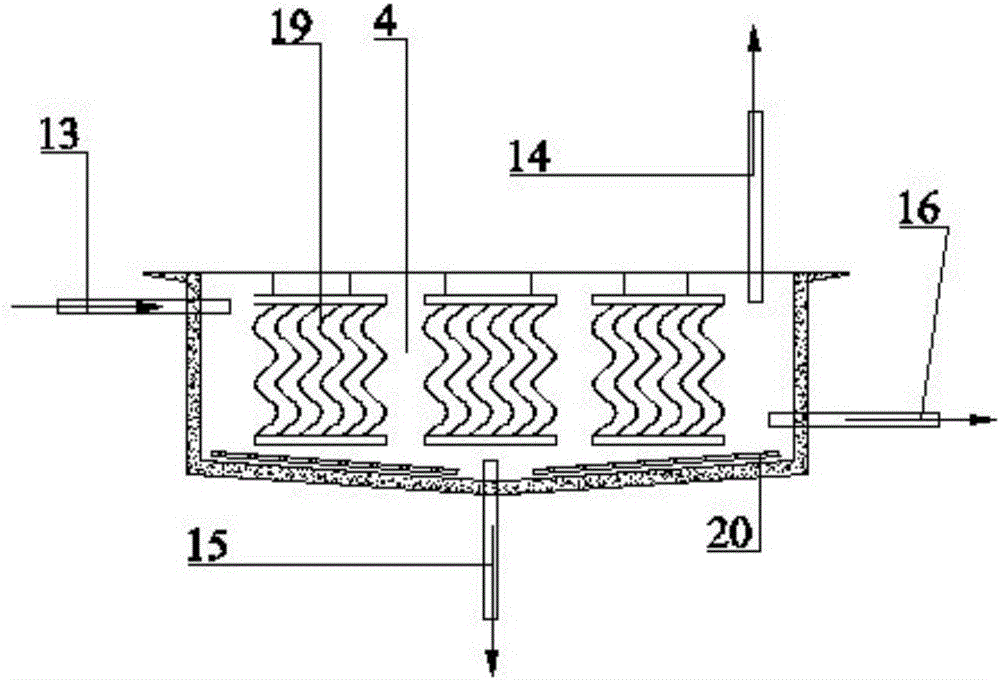

[0024] Specific embodiment two: This embodiment is described in conjunction with the figure. The difference between this embodiment and specific embodiment one is that: a membrane module 19 and an aeration device 20 are arranged in the MBR4; the material of the membrane module 19 is polytetrafluoroethylene, Polyethylene polypropylene, polyvinylidene fluoride or zeolite molecular sieves. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

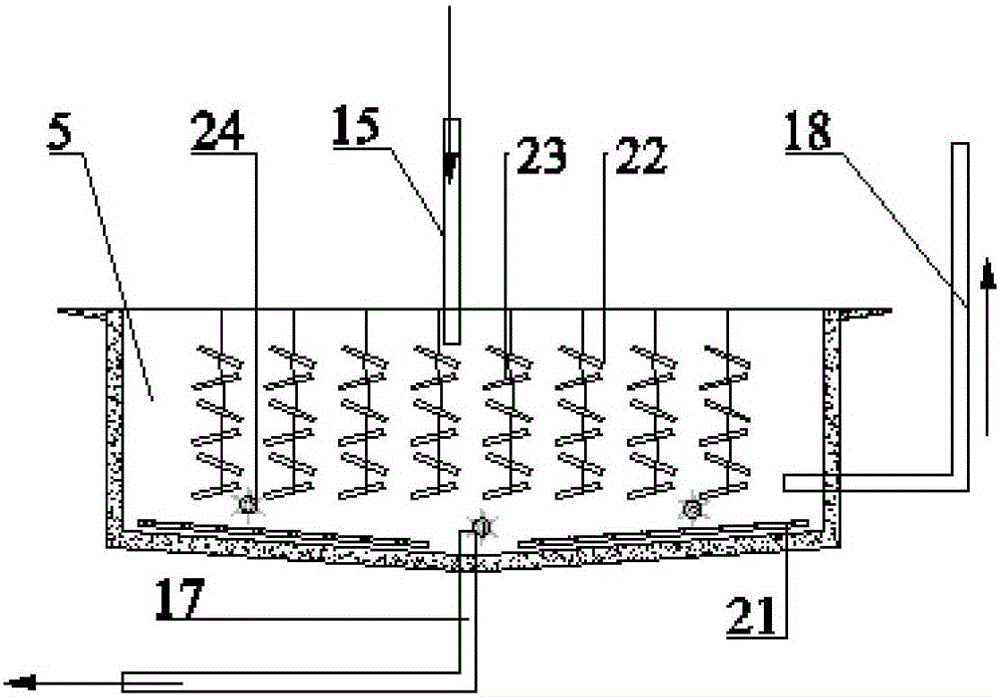

[0025] Specific embodiment three: This embodiment is described in conjunction with the figure. The difference between this embodiment and specific embodiment one is that the micro-animal biological bed 5 is provided with a micro-aeration device 21, a micro-animal carrier 22, a micro-animal 23 and a flow-pushing device 24 ; The micro-animal carrier 22 is a combination of fillers, elastic fillers, or made of nylon material, superfine fiber bundle material, polypropylene fiber bundles, polyethylene fiber bundles, etc. obliquely staggered rolling or arranged horizontally and vertically. Other compositions and connection methods are the same as those in Embodiment 1.

[0026] Embodiment 4: This embodiment is described in conjunction with the drawings. The difference between this embodiment and Embodiment 1 is that the micro-animal 23 grows and attaches to the micro-animal carrier 22, and the micro-animal 23 is a micro-animal that preys on sludge . Other compositions and connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com