System and treatment method of graded recovery of pigments and sugar from molasses

A technology for molasses and pigments, which is applied in the system of graded recovery of pigments and sugars in molasses and its treatment field, which can solve the problems of pollution, increase of osmotic pressure, waste of washing and filtering water, etc., and achieve the effect of avoiding a large amount of high-salt wastewater and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

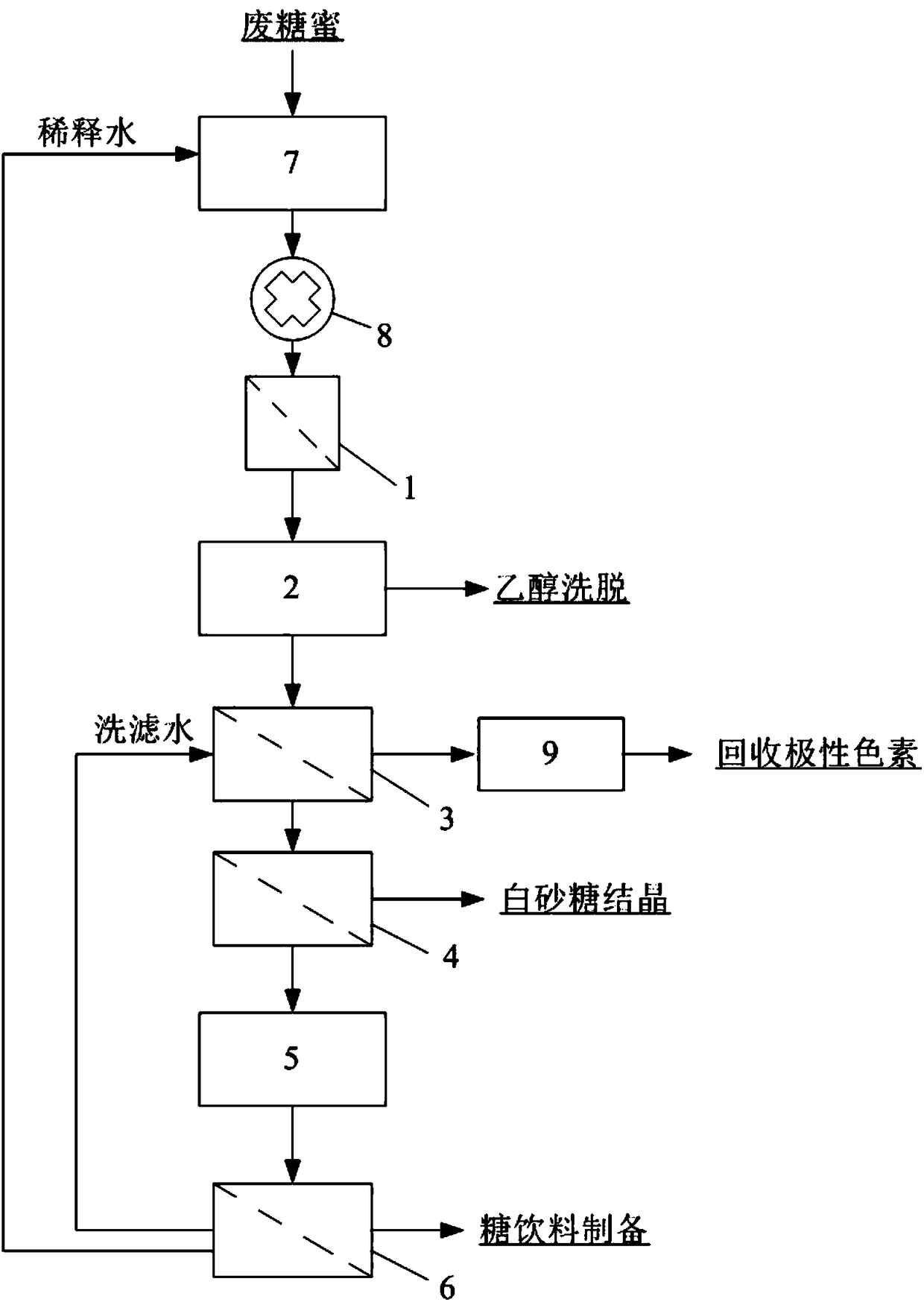

[0102] Present embodiment provides a kind of system of graded recovery pigment and sugar in molasses, such as figure 1 As shown, the system includes sequentially connected dilution device 7, separation device 8, microfiltration membrane treatment device 1, non-polar resin adsorption device 2, ultrafiltration membrane treatment device 3, nanofiltration treatment device 4, desalination device 5 And reverse osmosis treatment device 6; Described system also comprises drying unit 9, and drying unit 9 is connected with the concentrated solution outlet of ultrafiltration membrane treatment unit 3; The washing water inlet of the ultrafiltration membrane treatment device 3 is connected;

[0103] Among them, the separation device 8 is a centrifuge, the microfiltration membrane module used in the microfiltration membrane treatment device 1 is a polyvinylidene fluoride tubular membrane module with a pore size of 0.1 μm, and the resin used in the nonpolar resin adsorption device 2 is macro...

Embodiment 2

[0110]The present embodiment provides a system for graded recovery of pigments and sugars in molasses. The system refers to the system in Example 1, the only difference being:

[0111] The microfiltration membrane module used in the microfiltration membrane treatment device is a polyethersulfone coiled membrane module with a pore size of 0.01 μm, and the resin used in the non-polar resin adsorption device is macroporous styrene resin; the ultrafiltration membrane used in the ultrafiltration membrane treatment device The filter membrane module is a polyamide roll-type membrane module with a molecular weight cut-off of 500Da; the nanofiltration membrane module used in the nanofiltration treatment device is a polyamide roll-type membrane module with a molecular weight cut-off of 300Da; the reverse osmosis membrane module used in the reverse osmosis treatment device It is a polyamide spiral membrane module, and the standard desalination rate of sodium chloride is 99.0%.

[0112] T...

Embodiment 3

[0118] The present embodiment provides a system for graded recovery of pigments and sugars in molasses. The system refers to the system in Example 1, the only difference being:

[0119] The microfiltration membrane module used in the microfiltration membrane treatment device is a zirconia tubular membrane module with a pore size of 0.05 μm, and the resin used in the non-polar resin adsorption device is macroporous styrene resin; the ultrafiltration membrane used in the ultrafiltration membrane treatment device The membrane module is a polyamide coiled membrane module with a molecular weight cut-off of 1000Da; the nanofiltration membrane module used in the nanofiltration treatment device is a polyamide coiled membrane module with a molecular weight cut-off of 200Da; the reverse osmosis membrane module used in the reverse osmosis treatment device is Polyamide spiral membrane module, the standard desalination rate of sodium chloride is 99.8%.

[0120] The processing method of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com