Cleaning agent, method and device for tubular membrane

A cleaning device, tubular membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

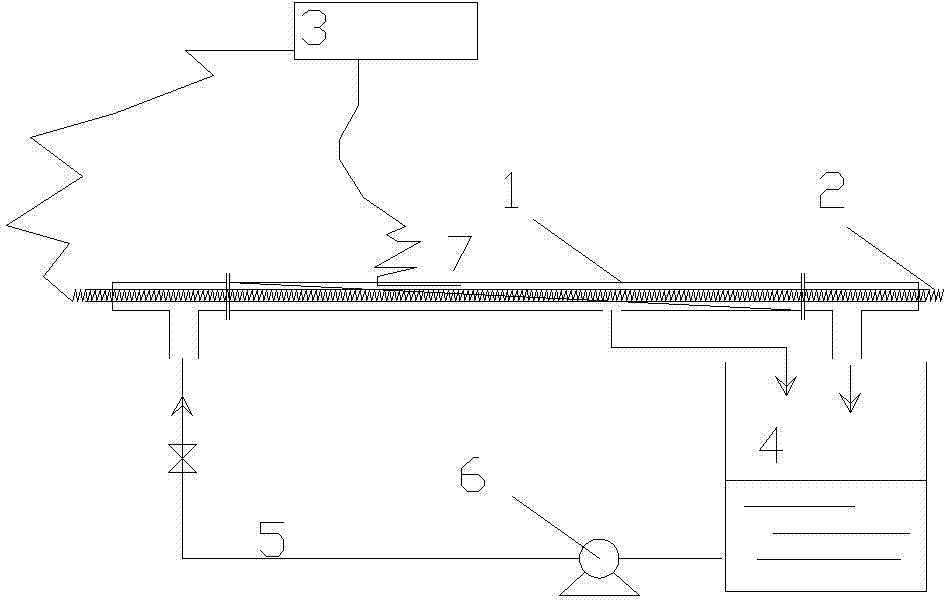

Image

Examples

Embodiment 1

[0026] The metal membrane that has been used for 3 years is used for cleaning experiments. The flux of the membrane tube has been attenuated by 20%, and the membrane flux is 40L / m 2 .hr, ordinary aqueous solution circulation cleaning has no obvious effect, and the device and cleaning method of the present invention are used for cleaning. First rinse the membrane tube with pure water, empty the water in the membrane tube, install a heating device and a temperature control device, prepare a methanol solution of 2% ammonia water, turn on the circulation pump, adjust the frequency to control the flow rate of the cleaning solution to about 2m / S, and open the membrane tube Heating device, the temperature is set at 65°C, the heating rate is 2°C / min, the timing starts when the temperature rises to 65°C, and the cleaning time ends at 45 minutes. Empty the lye in the membrane tube, rinse the membrane tube with pure water to neutral, then drain the water in the membrane tube, prepare a m...

Embodiment 2

[0028] The metal membrane that has been used for 3 years is used for cleaning experiments. The flux of the membrane tube has been attenuated by 20%, and the membrane flux is 40L / m 2 .hr, ordinary aqueous solution circulation cleaning has no obvious effect, and the device and cleaning method of the present invention are used for cleaning. First rinse the membrane tube with pure water, empty the water in the membrane tube, install a heating device and a temperature control device, prepare a 1% NaOH ethanol solution, turn on the circulation pump, adjust the frequency to control the flow rate of the cleaning solution to about 2m / S, and open the membrane tube Heating device, the temperature is set at 80°C, the heating rate is 5°C / min, the timing starts when the temperature rises to 80°C, and the cleaning time ends at 60 minutes. Drain the lye in the membrane tube, rinse the membrane tube with pure water to neutral, then drain the water in the membrane tube, prepare 1% ethanol solut...

Embodiment 3

[0030] The metal membrane that has been used for 3 years is used for cleaning experiments. The flux of the membrane tube has been attenuated by 20%, and the membrane flux is 40L / m 2 .hr, ordinary aqueous solution circulation cleaning has no obvious effect, and the device and cleaning method of the present invention are used for cleaning. First rinse the membrane tube with pure water, empty the water in the membrane tube, install a heating device and a temperature control device, prepare a 2% triethanolamine propanol solution, turn on the circulation pump, adjust the frequency to control the flow rate of the cleaning solution to about 2m / S, and turn on For the membrane tube heating device, the temperature is set at 90°C, the heating rate is 6°C / min, the timing starts when the temperature rises to 90°C, and the cleaning time ends at 60 minutes. Drain the lye in the membrane tube, rinse the membrane tube with pure water to neutral, then drain the water in the membrane tube, prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com