Hollow fiber ultrafiltration membrane organic fouling blockage cleaning method

A technology of ultrafiltration membrane and fiber, which is applied in the field of membrane cleaning, can solve problems such as difficult recovery of membrane flux and pressure difference, inability to remove gel layer, and degradation of membrane system performance, achieve good cleaning effect, and solve short water production cycle , The effect of less secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

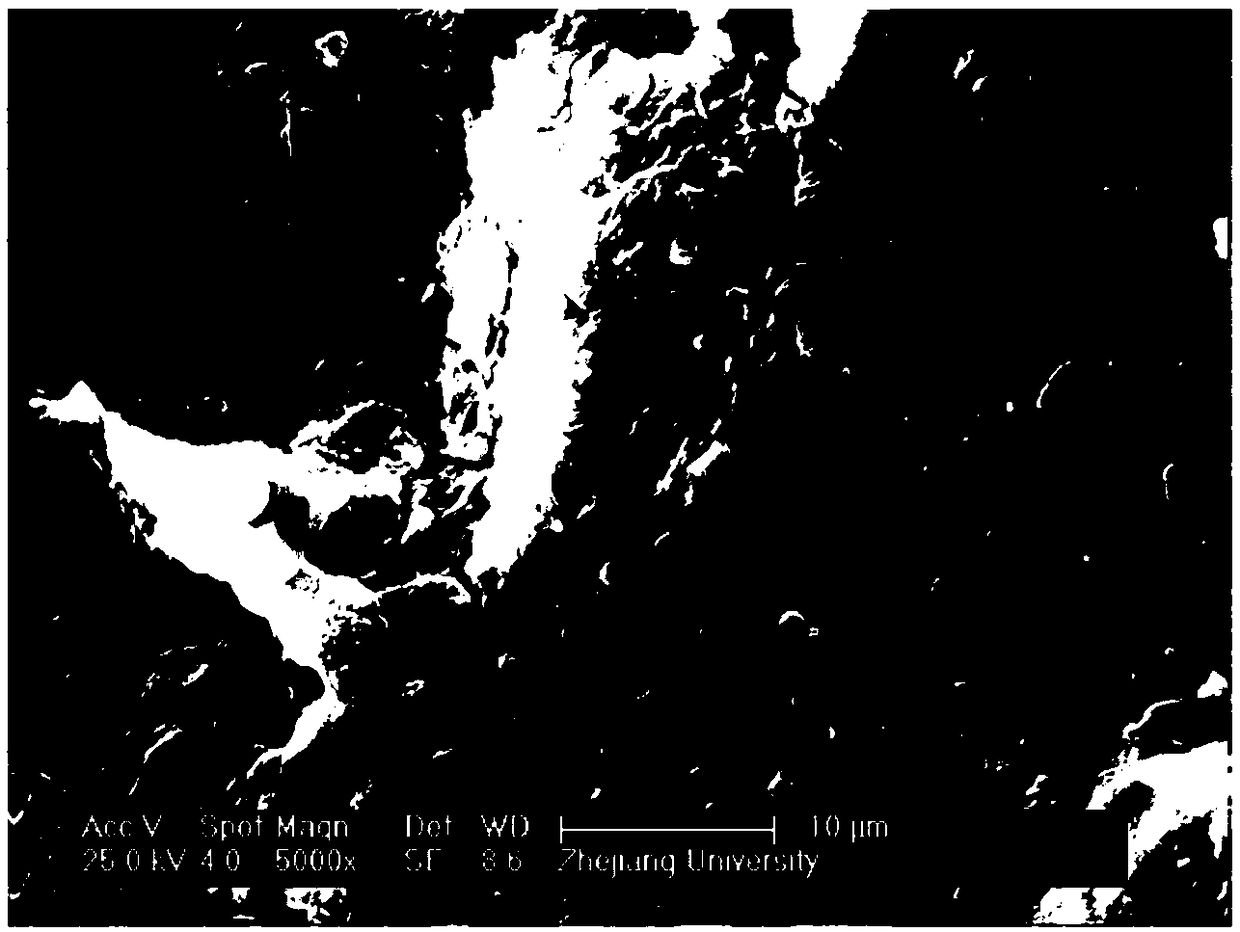

[0046] A power plant uses the secondary sewage from the sewage treatment plant as the production water source, and uses aerated biological tanks and ultrafiltration membranes to further treat the secondary sewage. During the operation of the system, the transmembrane pressure difference increases, and the chemical cleaning efficiency of conventional acid and alkali is low , The output drops obviously, etc., take the ultrafiltration membrane silk for in-depth analysis. The analysis results show that the fouling layer on the surface of the membrane is composed of a relatively dense fouling layer at the bottom and particles attached to the top, and the mass fraction of C, N, and O in the polluting substances reaches more than 96%.

[0047] figure 1 Schematic diagram of the ultrafiltration membrane before cleaning, figure 2 It is a schematic diagram of the ultrafiltration membrane cleaned by the present invention. After the chemical cleaning, the water production flux and the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com