Venturi apparatus for strengthening liquid-membrane crushing effect

A Venturi tube and strengthening liquid technology, which is applied in the direction of combustion method, combustion chamber, combustion equipment, etc., can solve the problem of the influence of the fuel atomization of the Venturi tube structure, which is rarely studied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described now in conjunction with accompanying drawing:

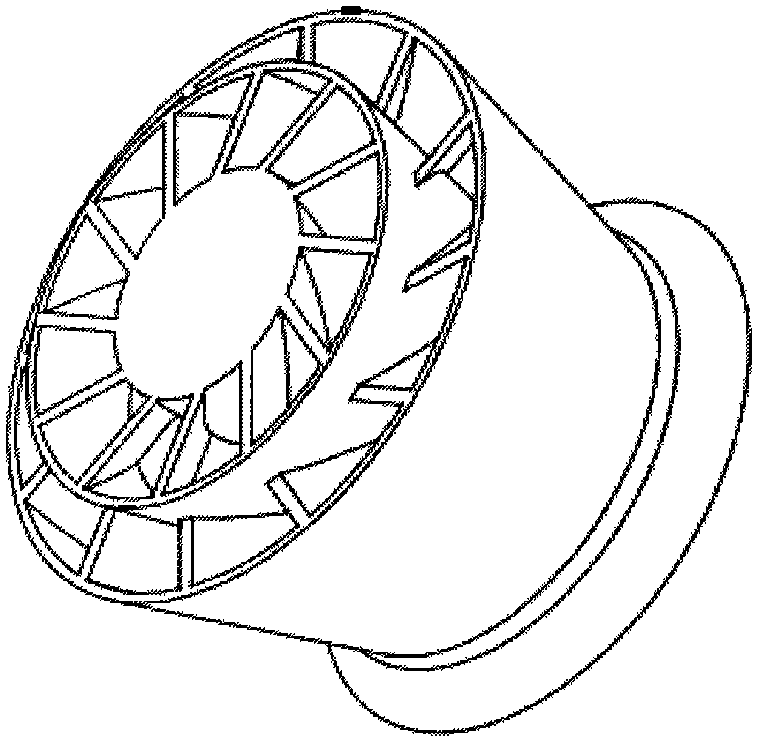

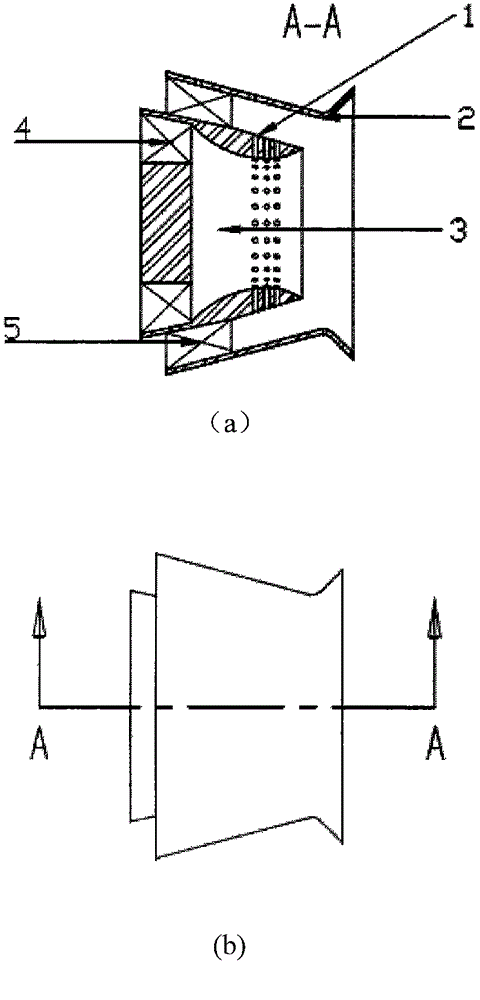

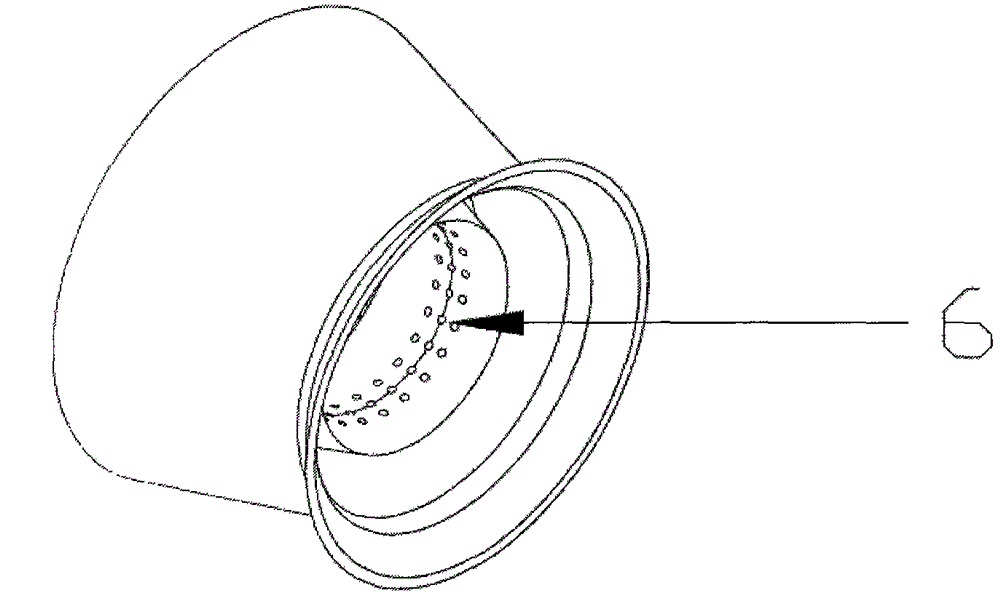

[0025] combine figure 1 , figure 2 , image 3 The present invention provides a new venturi tube for enhancing atomization effect, a swirler composed of the venturi tube and a gas turbine combustor formed by the swirler. figure 1 3D view of the two-stage cyclone, figure 2 , image 3 Indicates the approximate location of the venturi opening area. Figure 4 , Figure 5 Indicates two arrangements, fork row and straight row. Image 6 Shown is a Venturi tube in boss mode. When the high-speed liquid film flows through the opening or boss area of the venturi tube, the complete liquid film will be disturbed. Reasonable arrangement of the hole or boss position can promote efficient atomization of droplets and make the droplet size more uniform , to improve the atomization effect.

[0026] The rear part of the traditional venturi tube is smooth. After the fuel forms a liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com